For many businesses today in logistics, supply chain, and transportation, innovation acquired through technology has become a key indicator of their competitiveness. Companies such as DHL, FedEx, and Amazon have built their empires based on a continuous improvement approach guided by innovation. By implementing innovative solutions, they could also become more responsible by integrating sustainability practices. According to the MHI Annual Industry Report in 2023, we can observe a significant increase in investments in innovation, which is becoming increasingly available for small and medium-sized businesses.

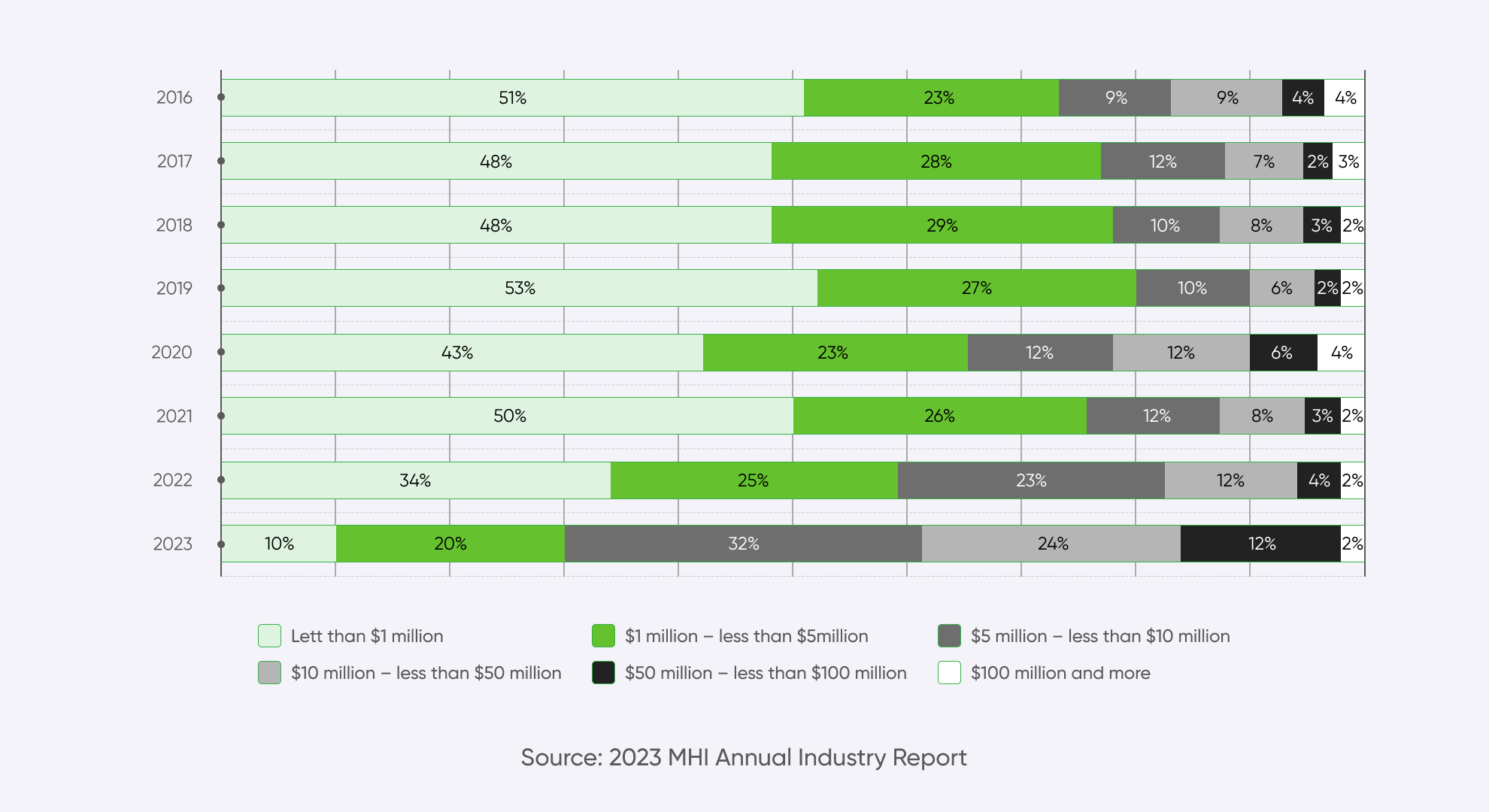

90% of companies plan to invest more than $1 million in supply chain resilience

Looking at the statement above, we may start to think about where these millions of dollars go, and the central question is if one million dollars is enough. Of course, it's not, especially when discussing a significant network of businesses in the entire supply chain. These results come from research and The Responsible Supply Chain Report provided by MHI. Ninety percent of surveyed companies plan to spend from $1 to $50 million on investments that can support their business operations and help them be more resistant to outside events.

The demand for modern solutions is increasing, especially in the investment in robust software responsible for keeping businesses up and running. This solution has also become available for small and medium-sized companies that can acquire custom software for nearly $50,000. This is not the bottom line, but this price estimates an average solution built from scratch to support businesses effectively in their daily operations.

Referring to total expenses for innovation between 2023 and 2025, there will be a significant shift compared to years before international crises like COVID-19. Companies could draw intelligent conclusions and want to be more flexible and ready to shift their business capabilities. Here is why investment in innovations is essential today:

Agile leadership. Companies want to implement leading models with agile approaches that improve anticipation and foster a better culture of adaptability to new business circumstances.

Diversifying revenue streams. Companies want to spread risk by expanding products/services. This can help them enter new markets, some failing due to external policy issues.

Digital transformation. Using technology to streamline operations improves the customer experience and helps them stay more competitive in challenging times.

Build a strong team. Invest in employee development and arm them with robust digital solutions that make their lives easier and help them be more flexible in the workplace.

Financial resilience. Investments must help manage cash flow, reduce expenses, and build reserves to meet economic challenges and take advantage of opportunities in the future.

38% of companies committing more than $10 million to supply chain transformation

An exciting trend in global investment emerges from a report showing a 19% increase in companies planning to spend $10 million on investments. This means nearly 38% of companies are committed to significant supply chain development investments. It raises questions about the implications for companies that overlook this trend and choose not to prioritize investments. For many, the conclusion may be obvious: companies neglecting investment could risk being pushed out of the market in the coming years.

Generating extra revenue

Investing in the supply chain can provide companies with a higher percentage of profits generated by innovation (higher return on investment), which can be used to fund new products, expand into new markets, or improve financial performance.

Asset protection and development

Business investments often result in the acquisition of new capabilities, enabling companies to share in the success and growth of the business, thereby protecting and expanding their assets.

Both-sides benefits

Some supply chain investments offer companies both ownership and profit sharing. This means that shipping companies that invest in custom software can provide a powerful tool to generate revenue and protect assets simultaneously.

Inventory optimization achieved 87% of all improvements

Among the various investment areas in the supply chain, inventory optimization is one of the most interesting. Despite appearances, distribution directly impacts transportation and supply chain density. The conclusion is simple: better stock-keeping results in lower requirements for warehouse space, lower costs, and compliance with shipping demand, leading to more sustainable shipping models with reduced truck traffic.

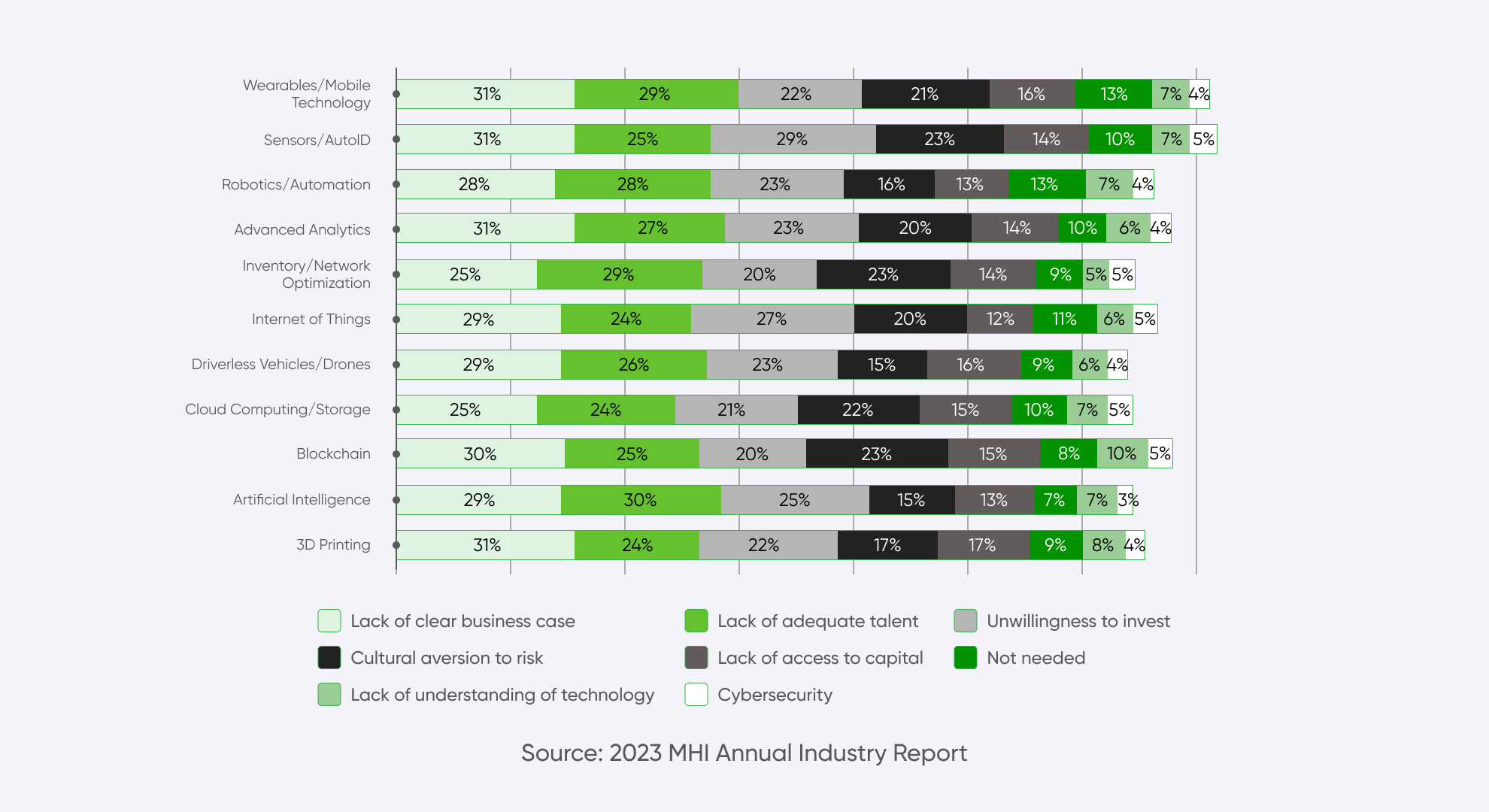

One of the investments in technology is covering inventory optimization, where served companies achieved 87% of all results by Inventory & Network Optimization. Nevertheless, for many companies, certain technologies are not easy to implement, which gives them many barriers and constraints that are difficult to tackle while implementing.

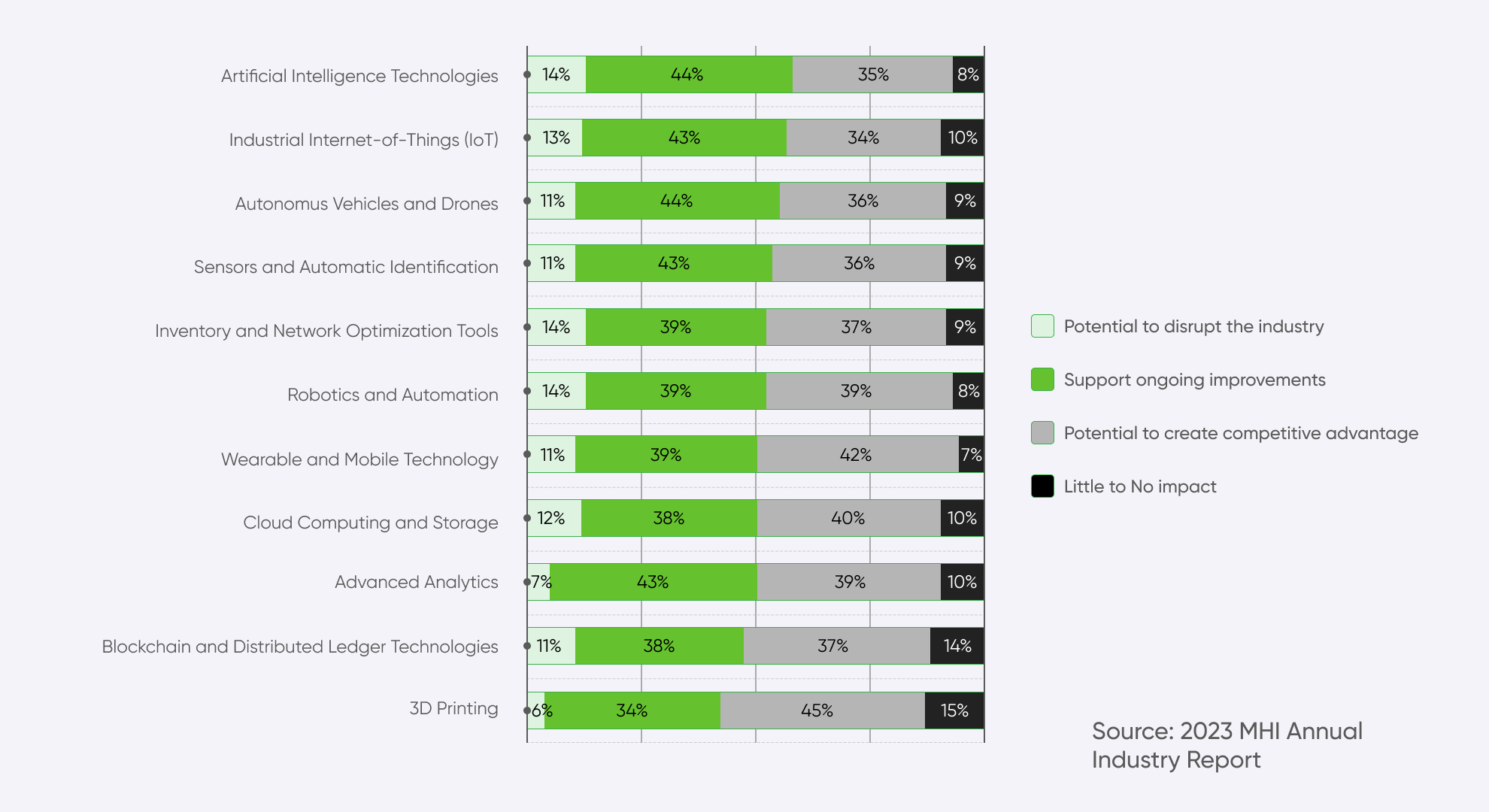

Here is what all investments in technology look like, with indicated significant barriers to investment in particular technologies.

All technologies above are based on custom software development. Custom software has various approaches in development and used techniques. Therefore, some of the indicated constraints can be easy to remove. It is also worth mentioning that small and medium companies can really benefit from custom software, as it can allow them to implement more sophisticated technologies in a much simpler way. This can give them a competitive edge with the lowest effort ever.

Final takeaway

We discuss significant investments in supply chain transformation. By optimizing inventory and creating custom software, we are facilitating technological advances for companies. Much of this can be appreciated, especially for small and medium-sized enterprises (SMEs), which can gain a competitive advantage with relatively low investment by achieving a top-tier service delivery model. Strategic investments drive growth, protect assets, and maintain competitiveness in today's dynamic business environment.

Adexin is a custom software development company that delivers top-quality customer software development services for supply chain, logistics, and transportation. We specialize in driving innovation among small and medium-sized businesses. With a deep understanding of the complexities of large business operations in our industries, we can help you become competitive in a highly challenging business landscape. Contact us today, and let's see how we can help drive positive changes in your market together.

Are you in search of a reliable tech partner?

Adexin can help with advanced logistics solutions

Contact us