Is inconsistent product quality, undetected defects, or compliance risks slowing down your business? Gain full control of your production, inspection, and reporting processes with AI-based quality control systems tailored to your industry and operational workflows.

Consulting

We can consult on constructing a practical and beneficial technical solution for your product.

Custom software

We deliver highly specialized, cutting-edge solutions for all niches of the logistics industry.

Dedicated teams

Jumpstart your long-term projects with a team of hand-picked professionals powered by AI.

Services

Technologies

- Adexin

- Services

- Custom software

- AI-powered quality control system development

AI-powered quality control system development

What quality control challenge are you solving today?

Lack of an AI-powered quality inspection solution

Lack of intelligent inspection management software tools

Lack of AI experts to build inspection management software

Lack of integration with ERP, MES, or CRM systems

No real-time AI visibility into defects and process deviations

Manual QA workflows based on spreadsheets and paper forms

Challenges in scaling AI-driven inspection processes

Disconnected production data and quality monitoring systems

Delayed, incomplete, or non-actionable quality reports

There is an AI-powered software solution for quality control

Flexible

Our AI-driven quality control software adapts easily to new compliance rules, changing product lines, and continuous improvement initiatives. Modular architecture and retrainable AI models allow your inspection processes to evolve without disrupting operations or rebuilding the system.

Comprehensive

From raw material inspection to final product release, we build AI-powered quality control systems that digitize and automate every QA stage. Machine learning and computer vision analyze inspection data in real time, detect anomalies, and ensure consistent quality across production, inspection, and reporting workflows.

Industry-oriented

We combine advanced AI development with deep expertise in manufacturing and logistics to deliver AI-powered quality control systems aligned with real operational challenges, regulatory requirements, and day-to-day inspection workflows across production environments.

Let’s build your AI-powered inspection management system

Our clients have trusted us for over a decade

- Foundation2011

Adexin has been operating continuously since 2011, amassing extensive skill and experience.

- Projects100+

We have successfully delivered more than 100 projects spanning different development areas.

- Clients70+

We value every client we have collaborated with and hope we can be the company of your choice.

Here are some of them

How to start cooperation

- 1

Set up a call

Share the issues you need to address and your vision of the solution.

- 2

Agree on a plan

Together, we'll define the necessary steps to achieve your goals in the most effective way.

- 3

Start a project

Begin boosting your company's productivity by solving your current challenges.

Book a free consultation to discuss your project

Still unsure about custom AI-powered quality control software?

Too expensive

While upfront investment may be higher, AI-powered systems reduce long-term quality costs by minimizing defects, rework, and manual inspections. You pay only for features that directly impact quality performance.

Too slow to develop

Our MVP-first approach delivers a working AI-powered quality control solution within weeks, allowing you to validate value early and expand functionality as ROI is proven.

High upfront costs

Using our AI-powered Adexin Tools Framework, we reduce inspection management software development costs by up to five times by reusing proven AI modules for analytics, workflows, and integrations.

Loss of control

You fully own your AI-powered quality control system, including models and data, without vendor lock-in, restrictive subscriptions, or loss of data ownership.

Hard to maintain

Built on modern, open technologies, our AI quality control platforms are easy to update, retrain, and extend as data volumes and inspection complexity grow.

Too complex for staff

With intuitive dashboards, AI-assisted recommendations, and role-based access, your teams can adopt the system quickly with minimal training.

Our work on software development for the industry

Check out our past projects

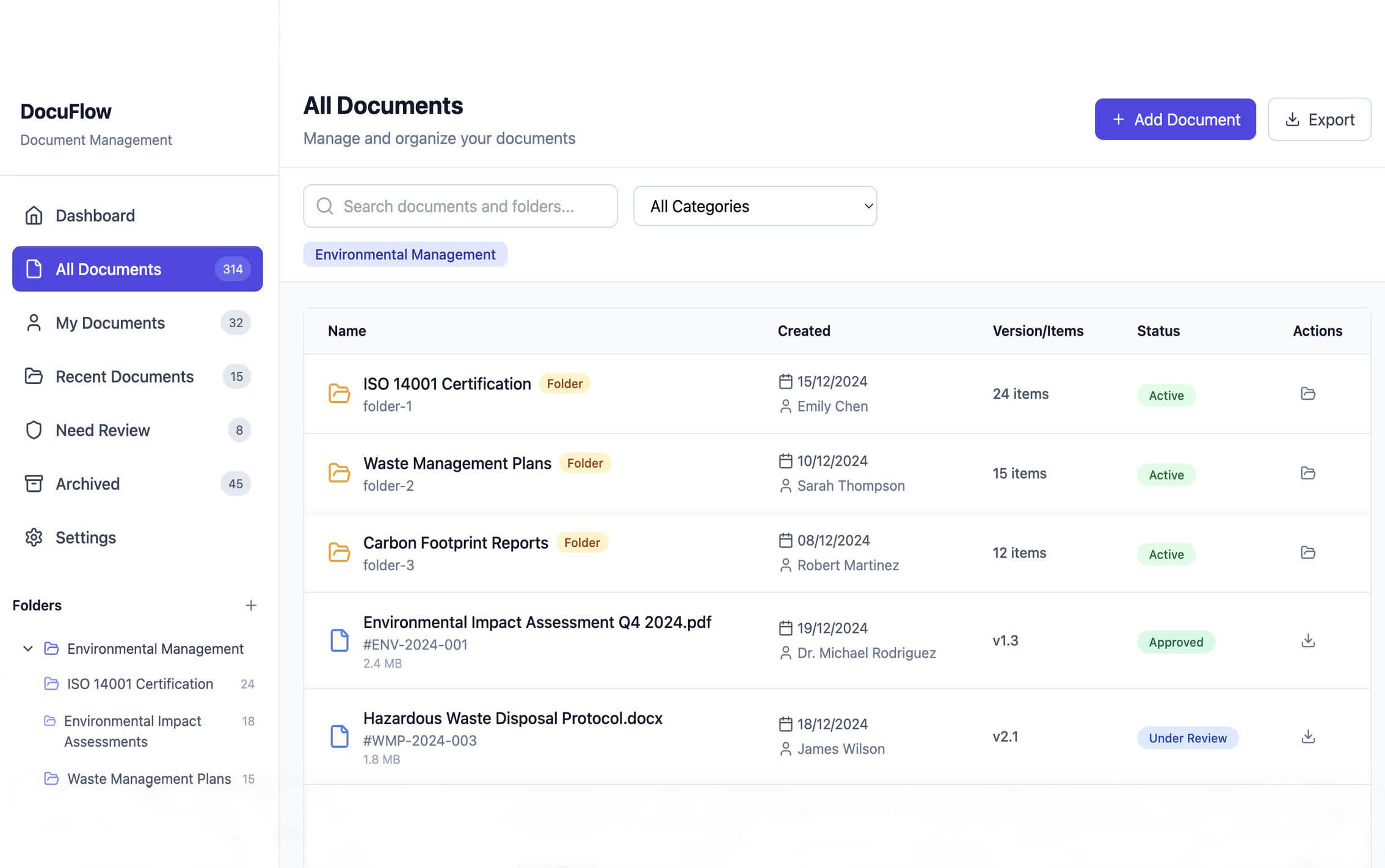

Document management platform for ISO certification

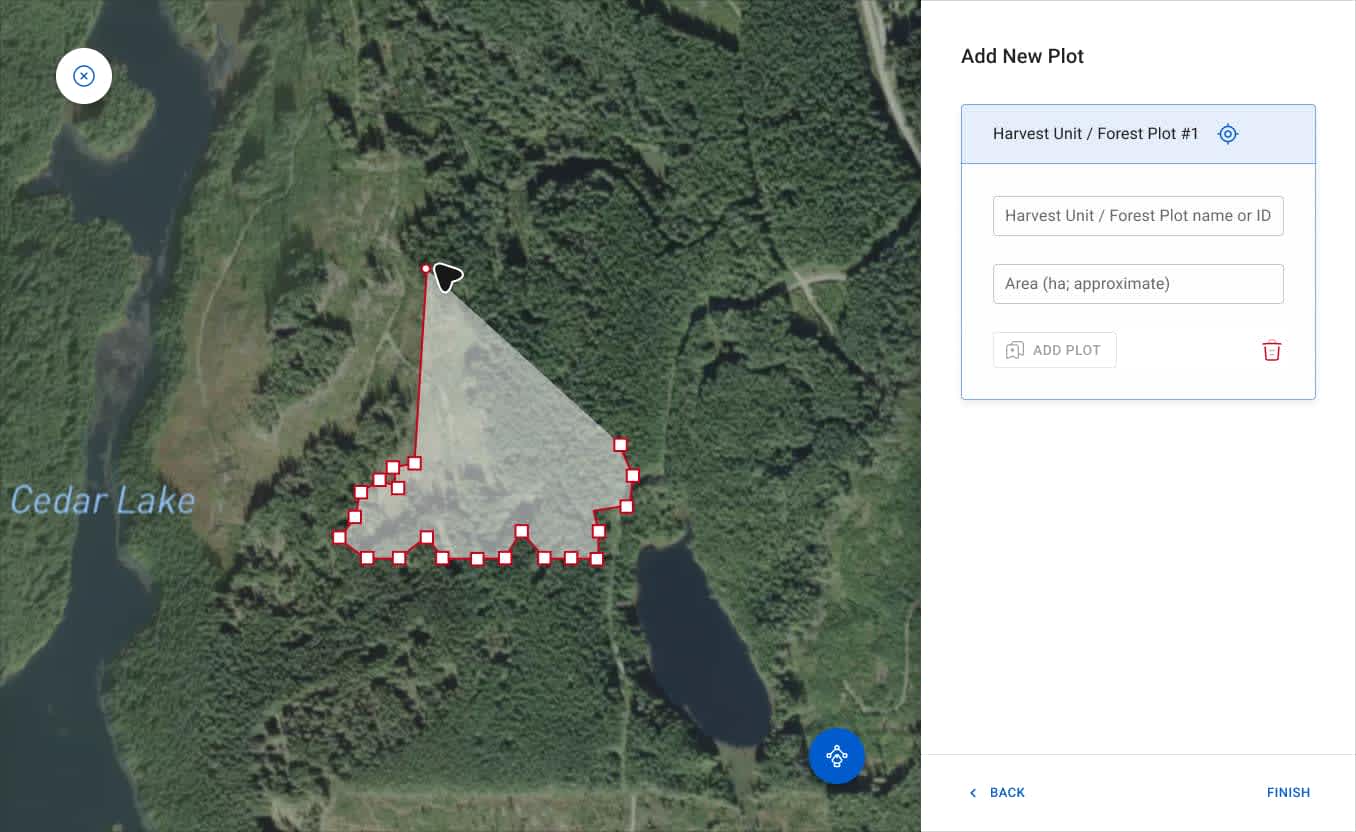

Blockchain-based Digital Material Passport app

Let Adexin guide your development

Key features of an AI-powered quality control system

Digital inspections and AI audits

Standardize inspection procedures with mobile-friendly digital forms enhanced by AI-driven checks and automated validation, improving accuracy, traceability, and consistency across inspections.

Intelligent compliance management

Automate compliance documentation, reporting, and traceability for ISO, FDA, GMP, and industry standards. AI continuously monitors deviations and flags compliance risks before audits occur.

Automated nonconformance handling

AI models detect anomalies, trigger corrective and preventive actions automatically, prioritize risks, and track resolution status to reduce repeat quality issues.

Predictive analytics and reporting

Access real-time dashboards with AI-powered insights into defect trends, yield performance, and compliance status, enabling faster and smarter quality decisions.

Integration-ready architecture

Seamlessly integrate with ERP, MES, IoT sensors, and CRM systems, creating a centralized AI-driven quality data hub across departments.

Secure audit trails

Maintain immutable, time-stamped records of inspections, approvals, AI decisions, and corrective actions to support audits and regulatory reviews.

Why choose Adexin for AI-powered inspection management system development?

Adexin Tools Framework

Save time and budget with prebuilt AI-powered modules for reporting, workflows, and integrations, accelerating your custom inspection management system delivery.

Deep logistics expertise

Our experience across manufacturing and logistics ensures AI-powered quality control systems aligned with real production challenges.

MVP first delivery

We deliver a functional AI-driven quality control platform quickly, allowing early validation and continuous improvement based on real inspection data.

Integrated dev approach

We work closely with your QA, compliance, and IT teams to ensure AI models, workflows, and integrations match operational and regulatory needs.

Scalable AI architecture

Developed for growth, our systems support multiple facilities, large inspection data volumes, and continuous AI model improvement.

Security first engineering

Enterprise-grade encryption, role-based access control, and secure cloud infrastructure protect sensitive inspection and production data.

FAQ

an AI-powered quality control system, and why do I need one?

An AI-powered quality control system is a software platform that applies machine learning, computer vision, and advanced analytics to automate, monitor, and continuously improve quality assurance processes. Unlike traditional QC tools, it analyzes inspection data in real time to detect defects, identify patterns, and predict potential quality risks before they escalate. This enables organizations to reduce defect rates, minimize rework and recalls, strengthen compliance, and gain full visibility into quality performance across production, logistics, and inspection workflows, turning quality control into a proactive, data-driven function.

Can it replace manual QA workflows?

Yes. An AI-powered inspection management system replaces spreadsheets, paper checklists, and fragmented tools with unified digital workflows enhanced by automated validation and intelligent checks. Inspection data is captured once through digital forms or devices, verified by AI models, and instantly shared across teams. This reduces manual errors, speeds up inspections and approvals, improves traceability, and allows QA teams to focus on root cause analysis, continuous improvement, and strategic quality initiatives instead of repetitive administrative tasks.

Can it handle regulatory compliance?

Absolutely. AI-powered quality control software embeds regulatory and industry-specific requirements directly into inspection workflows to ensure consistent execution. Automated documentation, electronic signatures, time-stamped audit trails, and AI-driven deviation detection simplify compliance with standards such as ISO, FDA, and GMP. The system continuously monitors inspection results, flags compliance risks early, and supports quick updates when regulations change, helping organizations reduce audit effort, avoid penalties, and demonstrate a strong commitment to quality and transparency.

Will it integrate with existing tools?

Yes. Our AI-powered inspection management systems are deeveloped to integrate seamlessly with ERP, MES, CRM platforms, IoT sensors, and custom databases. This enables automatic data exchange between quality, production, and supply chain systems, eliminating manual data entry and silos. By consolidating inspection results, operational metrics, and AI-driven insights into one platform, organizations gain a unified view of quality performance and can make faster, more informed decisions across departments.

Is inspection management software secure and cloud-based?

Yes. Our AI-powered quality control systems are cloud-native and built with enterprise-grade security at every level. All inspection and production data is encrypted in transit and at rest, with role-based access control, authentication mechanisms, and detailed audit logs. Secure cloud infrastructure ensures high availability, reliable backups, and disaster recovery, while enabling authorized teams to access real-time quality data securely from multiple locations and production sites.

How quickly can an AI-powered inspection management system be deployed?

Deployment timelines depend on system scope, but our MVP-first approach enables rapid delivery. A core AI-powered inspection management solution can typically be launched within weeks, covering essential inspection workflows and analytics. Prebuilt components from the Adexin Tools Framework accelerate development, while iterative deployment allows early validation, continuous refinement of AI models using real inspection data, and scalable expansion as operational and compliance requirements evolve.