Get better control over your warehouse operations with fully integrated, AI-powered custom software development for a top warehouse management system.

Consulting

We can consult on constructing a practical and beneficial technical solution for your product.

Custom software

We deliver highly specialized, cutting-edge solutions for all niches of the logistics industry.

Dedicated teams

Jumpstart your long-term projects with a team of hand-picked professionals powered by AI.

Services

Technologies

- Adexin

- Services

- Custom software

- AI-powered warehouse management system development

AI-powered warehouse management system development

Where we can help

We deliver tailored AI-WMS solutions that digitize and optimize your entire warehouse ecosystem from receiving to shipping, analytics, and beyond.

Inventory management

Efficiently manage inventory using our AI-driven custom software's built-in features to identify and remove aging inventory, ensuring balanced inventory levels and eliminating surplus. Improve stock control and good management while avoiding missing and damage.

Shipping process

Streamline the shipping process by seamlessly creating orders within a custom AI-powered shipping feature in development within your warehouse management system. Optimize workflow to ensure timely and accurate deliveries.

Picking and packing

Get AI-enhanced, custom-built-in functionality for order picking integrated with stock. Efficiently manage the packing process with smart labeling and easy-to-track inventory management with barcode scanners. Increasing productivity and accuracy before any outbound.

Order management

Utilize AI-enabled custom software to streamline order processing. Ensuring a smooth and organized flow from order creation to fulfillment. Remove paperwork from your business environment and enable your personnel with digital, data-driven solutions tailored to their needs.

Analytics and KPIs

Access detailed AI-powered analytics and key performance indicators (KPIs) through custom software features with dashboards and interfaces with real-time metrics. Provide valuable insight into warehouse performance and enable data-driven decision-making for your personnel and customers.

Receiving processes

We deliver AI-supported software features for optimizing the receiving process. You can ensure a seamless transition from the inbound to their organized distribution in the warehouse. Keep stock organized on its shelves upon arrival.

Technology integration

Seamlessly integrate the warehouse management system with other technologies in the company, such as RFID, barcode scanners, and IoT devices. Digitalize processes, reduce errors, and decrease stock losses.

Traceability of goods

Increase traceability by using AI-powered software to accurately track the movement of goods in the warehouse and after shipping. Improve inventory management and monitoring precision with track and trace technology and digital proof of delivery.

Returns management

Effectively manage product returns with AI-assisted return packaging management software features, such as KLT. Provide your company with sustainable, eco-friendly technology for smooth and environmentally responsible practices.

Transportation integration

Integrate with AI-enabled transportation management systems (TMS) for a holistic approach to efficiently plan routes and optimize transportation. Ensure on-time delivery and cost-effective warehouse operations with maximum customer satisfaction.

Start your custom WMS project today

How custom AI-powered WMS helps

Define your warehouse operations with intelligent AI-powered automation and analytics that optimize logistics, transportation, and supply chain integration.

Warehouse space and costs

The WMS analyses space utilization using AI algorithms, minimizing waste and lowering material handling costs. It also lowers costs that arise from losses and time spent on warehouse searches. The system enables AI-driven material rotation, which increases warehouse space efficiency and minimizes storage expenses.

Inventory visibility

The WMS provides real-time AI-powered inventory tracking visibility. That's another way to prevent losses and backorders and get accurate delivery estimates. This shortly leads to increased customer satisfaction. It is a crucial fact that automation of these processes helps with AI-enabled inventory tracking and replenishment.

Efficient operations

The WMS assigns tasks based on employee skills and AI task optimization. This means that processes can be digitized, and proximity and equipment can be implemented. You can get AI-driven job forecasting and intelligent scanning, which increases productivity, reduces double-checking, and improves picking accuracy.

Traceable materials

The WMS makes it easy to track inventory materials using a coding system such as LOT, Batch, and serial numbers. This provides full AI-enabled traceability and reduces redundancy when implemented with barcode labeling and digital inventory tracking. Accurate inventory planning and allocation can be ensured, as well as real-time AI system updates.

Optimized supply chain

A WMS transform warehouse operations. Implementing a WMS leads to increased operational efficiency and cost reduction. Warehouse processes and information exchange with internal and external partners can be significantly improved. Broader AI-powered supply chain processes can be optimized.

Internal automation

A WMS allows you to integrate AI-driven automation technologies into your warehouse. You can integrate devices and machines based on IoT connectivity. In this way, you can simplify processes and increase scalability. In this way, you support continuous AI-driven operational improvement.

Shipment management

The WMS effectively manages the scheduling of inbound and outbound shipments. You can optimize movements based on available manpower and equipment. It connects with AI-enabled transportation management systems (TMS) to optimize your other supply chain systems further.

Continuous improvement

The WMS is used as an AI-powered technology tool for continuous improvement. It enables incremental deployment and updates with newly developed features. The cloud-based AI WMS facilitates immediate updates and reduces the need for large IT teams.

Book a free consultation to discuss your project

Why Adexin

A unique symbiosis of education, AI expertise, and practical experience helps our company solve customer satisfaction tasks with top quality.

Adexin Tools

We leverage our proprietary AI-driven Adexin Tools, a ready-made codebase built on our industrial expertise, to accelerate project launches and cut development time by up to 5 times. It includes solutions for data management and outdoor tracking.

Expert group

Our AI-powered expert group offers direct access to top specialists who can assist with technical and industry-specific challenges, quickly assembling and integrating dedicated teams for your projects.

Industrial focus

We continually enhance our logistics expertise, adopting AI and machine learning technologies to drive industry growth and deliver better results for our clients.

Effective process

Recognized by Clutch among the top logistics software developers, Adexin ensures high-quality solutions by aligning with client goals and maintaining consistency across all business processes.

Scalable solutions

We develop AI-driven logistics software with built-in scalability, enabling future growth and advanced predictive features at minimal cost.

Full-stack development

Our AI-powered full-stack teams accelerate your digital transformation with faster time-to-market, improved efficiency, and enhanced customer service.

Adjustable process

We offer flexible contracts and adaptable processes to expand your teams, add new AI features, and optimize your final product as your needs evolve.

Cloud-based solutions

Cloud technology powers our AI-driven logistics solutions, enhancing agility, flexibility, performance, and innovation while reducing operational costs.

Industries

We provide the best AI-enhanced WMS systems for specific industries in our respective niche. We are focused experts in defined areas of business.

Logistics

Integrate AI into your warehouse operations with our WMS solution. Streamline order processing by combining it with complex internal operations. Gain full control over your goods flow and data insights with real-time visibility. Reduce costs and maximize overall operational efficiency.

Transportation

Streamline outbound shipment management and related transportation operations with our WMS, which tracks in real time from the warehouse to the destination. Use AI analytics for shipment optimization and reduce transportation time with lower shipment frequency.

Supply Chain

Get a comprehensive outlook and full control of your supply chain with our AI-driven WMS custom development. Take advantage of complex visibility to optimize processes and minimize fulfillment time, and increase process agility by leveraging data-driven decision-making.

Our case studies

Take a closer look at industry-related projects that help our clients gain a competitive edge.

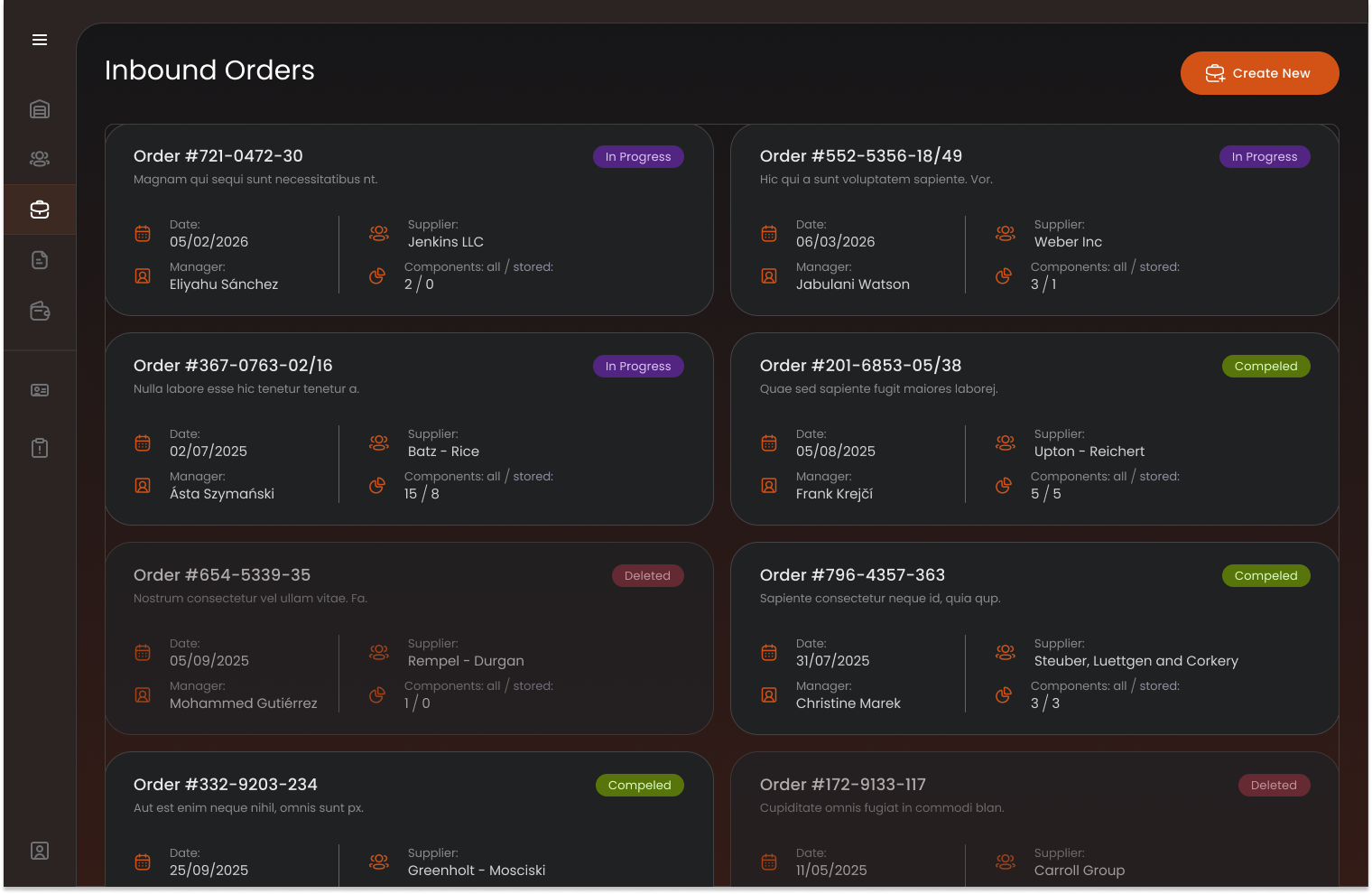

Lightweight WMS for manufacturing operations

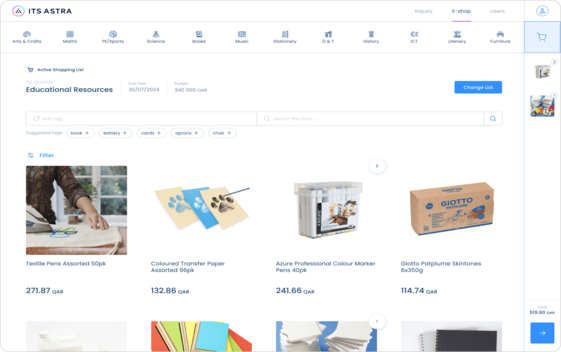

eProcurement solution for educational resources

Let Adexin guide your development

Main stages of AI-powered WMS development

We drive innovation with AI software solutions customized to your warehouse operations.

- 1

Understanding needs

1 weekThis step usually includes a series of meetings between you and our teams to discuss your business needs and pains. Also, we suggest signing an NDA to protect your sensitive information.

- 2

Solution and estimation

1 weekWhen requirements are clear enough, our team of experts determines the best suitable solution and provides a rough estimation of required time and resources, based on their extensive experience.

- 3

Project planning

1 weekWhen we understand the scope of the project, we will jointly plan the budget, timeline, and team structure. Also, this phase includes drafting an official agreement.

- 4

Phase 1.0

~3-12 monthsAdexin strongly recommends determining which functions and features of the new custom software are critical for the business and need to be implemented and tested in the first place. This phase can also be called the MVP phase. Usually, we follow the Kanban methodology during the logistics software development process. This gives the project flexible planning, fast output, clear focus, and transparency during the development cycle. We apply a full-picture reporting approach to make sure all parties are clear about the progress. This approach includes each team member's daily status reports, the whole team's weekly reports, biweekly demos, and monthly invoicing.

- 5

Phase 1.0 test

~1-2 monthsGetting the initial feedback from real users is very important. Having an MVP helps you to test your assumptions and business model. It allows you to really understand how users use the software, what should be added, and what needs to be fixed in the next development process.

- 6

Phase 2.0 and more

as much as neededCongrats, your first test showed that the project is promising and worth expanding. We will be glad to continue working on your project and grow together. The next phases can contain advanced features, additional functions, and logic requested by your users.

Our certifications in logistics

FAQ

You can better recognize crucial considerations about AI-powered warehouse management system development (WMS) from the following questions and answers. Learn how AI-driven automation adds flexibility and business freedom.

What is the WMS system software?

Warehouse management system (WMS) software is an application designed to manage and optimize warehouse or distribution center operations. It includes inventory tracking, order processing, and general warehouse management.

One of the primary functions of a WMS is to provide AI-enhanced, real-time visibility of inventory levels. It allows companies to track the flow of goods intelligently using predictive analytics. This enables proactive monitoring of inventory levels and ensures accurate stock management, reducing the risk of running out or overstocking.

The WMS streamlines the order fulfillment process, optimizing order picking and, in subsequent stages, packing and shipping. AI automation supports dynamic order prioritization and smart workflow adjustments. A WMS can help significantly reduce errors and increase the overall speed of order processing through data-driven decision-making.

What are the four types of warehouse management systems?

Four main types of warehouse management systems (WMS) meet different business needs and technology priorities:

- Standalone WMS. A standalone WMS operates as an independent system dedicated solely to warehouse management. This type is chosen by companies looking for a specialized solution focused solely on optimizing and streamlining warehouse operations without the complexity of broader business applications. The best option for this WMS solution is custom AI-enabled software development for predictive efficiency and automation.

- Enterprise resource planning WMS. ERP WMS integrates seamlessly with broader enterprise resource planning systems. This type of WMS provides a unified approach to business processes by integrating warehouse management functions into a comprehensive package. It enables organizations to manage warehouse operations and other aspects of their business through a centralized system. You can use AI integration services to connect WMS with ERP for predictive demand planning and smart inventory balancing.

- WMS in the cloud. Cloud-based WMS solutions are hosted on cloud platforms. They offer excellent scalability and AI-driven performance monitoring. This type of WMS allows companies to leverage the power of the cloud by facilitating remote access and real-time AI analytics. It also reduces the burden of maintaining local infrastructure while enabling adaptive scaling based on business patterns.

- Open-source WMS. Open-source WMS provides systems with a source code that is publicly available for modification. This type allows companies to customize the software to meet their unique requirements. An open-source system fosters a community-based AI innovation approach, encouraging collaboration and experimentation with machine learning modules for warehouse optimization.

How much is a warehouse management system?

Determining the cost of a warehouse management software requires consideration of several factors that affect the overall investment. Here is a more comprehensive overview:

- Size and complexity of the business. The scale and complexity of business warehouse operations play a key role in determining the cost of a WMS. Larger companies with complex supply chains and extensive warehouse inventory management software needs may require a more sophisticated and feature-rich system, which can impact overall costs.

- Features and functionalities. The specific features and functions required by a company have a significant impact on the cost of a WMS. Basic systems with basic features may have a lower initial cost. More advanced features, such as real-time analytics, automation, and integration capabilities, may add to the higher price.

- WMS type. Different types of WMS, such as standalone, integrated with ERP, cloud-based, or open-source, have different cost structures. Standalone systems may have lower upfront costs, while cloud-based warehouse management solutions often involve subscription fees. ERP-integrated WMS systems can be part of a broader software package. These factors are affecting the overall price.

- Implementation costs. The implementation process involves additional costs. It may include software installation, data migration, and employee training. The complexity of the implementation can affect overall costs. Companies should budget for software licensing and the professional services needed for a successful implementation.

What is the value of warehouse management?

The overall value of warehouse management goes beyond mere logistics. A WMS contributes significantly to a company's overall productivity and future success. Here are four key benefits:

- Improved inventory accuracy. Efficient warehouse management systems (WMS) improve inventory accuracy by providing real-time insight into inventory levels and multiple warehouse locations. Accurate inventory data reduces the risk of out-of-stock or excess inventory.

- Improved operational efficiency. The WMS optimizes warehouse processes such as order picking, packing, and shipping. Automation of routine tasks streamlines warehouse operations, reduces manual errors, and increases overall productivity.

- Improved supply chain management. A WMS is key in broader supply chain management, providing insight into inventory movement, order processing, and overall warehouse performance. By facilitating data-driven decision-making, companies can respond quickly to market changes.

- Cost reduction. Implementing an effective WMS results in cost reductions in a variety of ways. Simply by minimizing order processing errors, companies avoid returns and re-shipment costs.

What does the WMS feature do?

Here are eight crucial WMS features:

- Accurate inventory tracking. Real-time monitoring of inventory levels, location, and movement in the warehouse

- Order processing and shipping. Streamlined workflows for efficient order picking, packing, and shipping

- Receiving and shipping management. Automated processes for receiving goods into the warehouse and managing shipments.

- Real-time visibility and traceability. Instant access to up-to-date information on inventory, orders, and overall warehouse activity.

- Demand forecasting and market predictions. Tools to predict future demand based on historical data and market trends.

- Automation functions. Automate routine tasks to improve efficiency, reduce errors, and increase overall productivity.

- KPI reporting and analytics. Robust tools to analyze warehouse performance. It is what generates reports and gains insights.

- Integration features. Seamless integration with other business systems, such as ERP and legacy systems, to ensure data consistency.

How does WMS improve your operations?

Warehouse management software streamlines operations using a variety of software engines and technologies. Here are selected facts about how WMS systems streamline operations:

- Streamlined processes. Modern warehouse management solutions optimize warehouse management workflows by automating tasks such as order processing, inventory control tracking, and replenishment.

- Reducing errors. Automation and real-time visibility minimize manual errors. It reduces inaccuracies in inventory management and overall warehouse management processes.

- Increased speed of order fulfillment. Automating and optimizing order picking, packing, and shipping with WMS speeds up the order fulfillment process.

- Real-time visibility and decision-making. A WMS provides real-time visibility and optimize warehouse operations. Here is how you're enabled with quick and informed decision-making.

What is the difference between custom WMS software and COTS?

Custom warehouse management system (WMS) software and commercial off-the-shelf (COTS) solutions offer different approaches to meeting companies' specific, unique needs. Here's a compilation of the key differences:

- Custom WMS software. A custom warehouse management system is specifically tailored to the unique requirements and workflows of a particular company. This approach involves developing a WMS solution from scratch or customizing existing software to match an organization's processes precisely.

- COTS (commercial off-the-shelf) WMS. COTS WMS solutions are off-the-shelf, standardized software packages that are commercially available and designed for the wider market. These solutions include features designed to meet typical warehouse management needs.

How long does the WMS software development process take?

The development timeline for warehouse management system (WMS) software can vary significantly depending on several factors. Here are the key factors that affect the timeline:

- Complexity of requirements. The complexity and depth of functions required in a WMS play a key role. A more complex system with advanced features may require a longer development time.

- Personalization needs. Suppose a WMS is being developed from scratch or requires extensive customization to fit specific business processes. Development time is likely to be longer. Customization increases complexity and may require more thorough testing.

- Integration requirements. Integrating a WMS with existing systems, such as enterprise resource planning (ERP) software or customer relationship management (CRM) systems. It can impact the development schedule.

What people need to be involved in the WMS custom software development process?

Successful development of a warehouse management software requires collaboration between different professionals with diverse skills. Here are the key roles that should be involved in the custom WMS software development process:

- Business analysts. Business analysts play a key role in understanding business requirements and translating them into technical specifications. They work closely with stakeholders to gather and document detailed functional and non-functional requirements for the WMS.

- Project managers. Project managers oversee the entire warehouse management system designed process, ensuring that the project remains on schedule and budget. They coordinate tasks and allocate resources internally.

- Software developers. Software developers are responsible for writing the code that brings the WMS system to life. They can be front-end and back-end developers, as well as database specialists. Their experience is crucial in building functionality and ensuring system performance.

How does WMS impact the supply chain and transportation?

Warehouse management systems (WMS) have a significant impact on both the supply chain and transportation. Here is how a WMS impacts these aspects:

- Increased inventory visibility. A WMS provides real-time visibility into inventory control levels, location, and movement within a warehouse. This visibility extends throughout the supply chain. It allows you to make informed decisions based on accurate and timely inventory information.

- Optimized order fulfillment. The WMS streamlines order fulfillment processes, improving the speed and accuracy of picking, packing, and shipping in the warehouse. This optimization directly impacts transportation, ensuring more efficient and timely order processing.

- Dynamic routing and transportation planning. The WMS can integrate with transportation management systems to facilitate dynamic routing and planning. Optimize routes based on real-time inventory control levels.