Digital technologies have launched a new era of efficiency and optimization of warehouse operations, leading to improved overall supply chain performance. This article provides an in-depth look at how digitization impacts warehousing in supply chain management.

We're exploring concepts such as warehouse tracking systems and deep integrations between warehouse management systems (WMS) and fleet management systems (FleetMS). This material also reveals the different types of operational management systems. You can learn more about what drives digital transformation in the supply chain management and warehousing industry.

How does digital transformation affect the supply chain and warehousing infrastructure?

We understand that for companies with limited resources, there is a huge dilemma based on what should be implemented in the warehouse; for small and medium-sized businesses digitization, ideas can be broad, but what is really needed in the warehouse can be questionable when it comes to solution expenses versus using your premises.

By looking through our experience, we want to make sure you get usable information. Rather, by using some of the cases of the implementation for our customer, like in cases of shipping document management platform for eTEU, a company from the UK, we want to show where and why such a DMS system was more valuable than other software solution deployments.

Let's analyze this case. When you're an SMB, it's obvious that digital technology should cover the first of what consumes most resources.

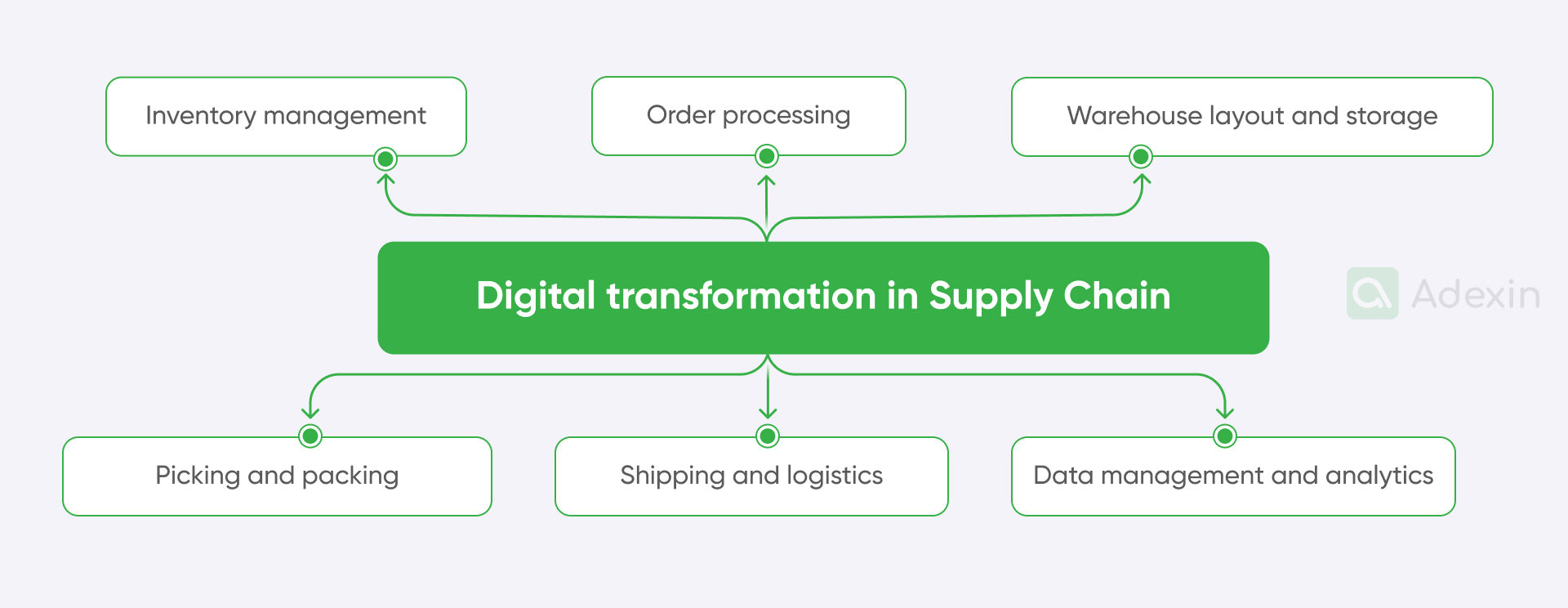

So, shortly, these are these areas:

Inventory management

Order processing

Warehouse layout and storage

Picking and packing

Shipping and logistics

Data management and analytics

Digital technologies in SCM and digital transformation approach

Every warehouse struggles with a tremendous amount of paperwork. I remember when I worked in UPS SCS in the Netherlands, where we stored shipping documents, such not in cabinets but in boxes stacked on euro pallets. There were thousands of paperwork documents in many pallets on the location, stored on shelves just like regular warehouse items.

This is because the law in the Netherlands requires the documents to be stored for 7 years. But this is not the only reason. The second reason for that was the need to handle all disputes by having access to historical data. So, you can only imagine what the process of data retrieval would look like if we were obliged to check some documents 4 months back. A warehouse forklift operation was needed to pick up the pallet from some high location, and then we dived into the boxes to find the right shipping document, let's say. Sometimes it takes 20 minutes, up to 1-2 hours, and sometimes involves 2-3 people. Of course, UPS wasn't an exception to this method of document handling. Almost every company does this in that way.

So, in fact, we clearly understand at Adexin where and why you need certain deployments in the first setup. When we transform document flow with DMS provided by the eTEU platform, many transportation industry companies and logistics companies in the supply chain can benefit from the DMS system for shipping documents. This is how digital technology affects the Supply Chain by removing constraints of paperwork in practice.

Need help with document management systems development?

Learn how we can boost your business processes

Explore moreDigital transformation initiatives from a wider perspective

Looking now more holistically at each part of the business in warehousing and supply chain, the complex landscape of supply chain management shows many more issues that should be resolved in the first iteration.

In this context, integrating digital solutions has brought transformational changes that significantly impact performance. So, one of the key elements in this area is the role of warehousing. Warehouses play a key role in the supply chain ecosystem, acting as the interface between storage, distribution, and inventory management.

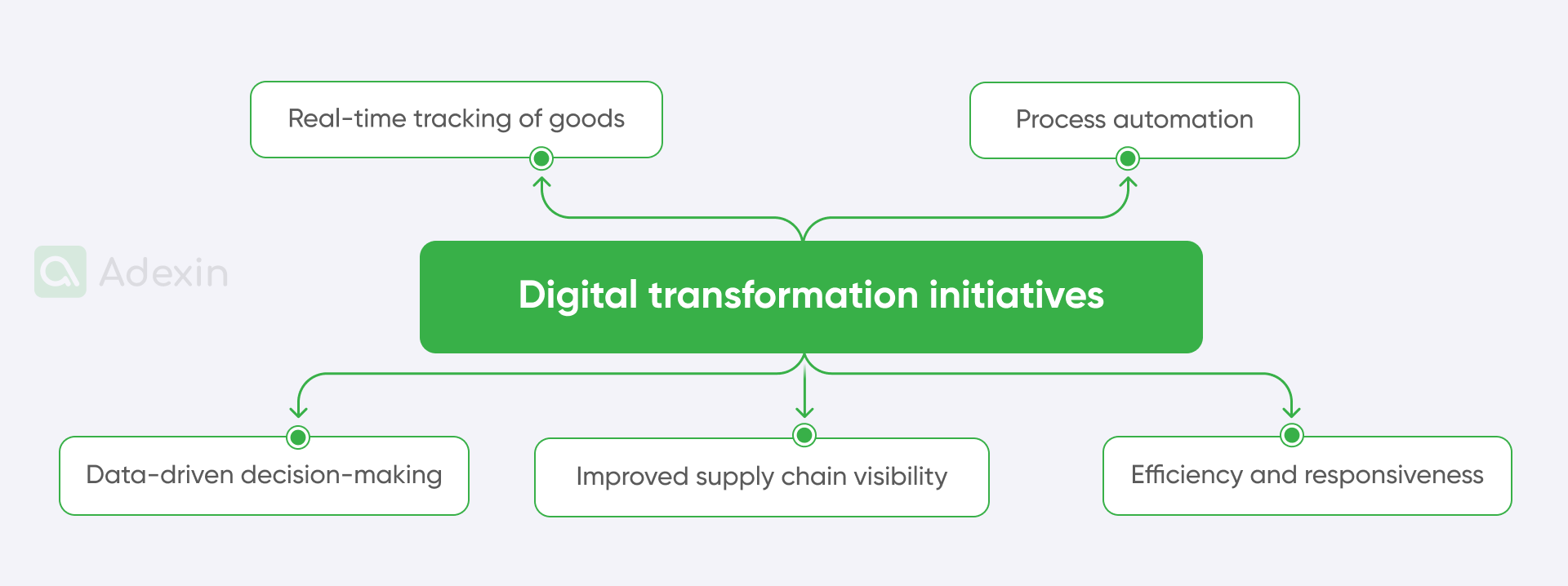

Digital transformation has had a significant impact on warehouse and supply chain performance, bringing innovation and improvements in key areas:

Real-time tracking of goods,

Process automation,

Data-driven decision-making,

Improved supply chain visibility,

Efficiency and responsiveness to customer needs

In addition to the digitalization trend, many other factors affect supply chain performance. For instance, globalization has led to longer supply chains, resulting in complex networks that increase the risk of interruption by geopolitics. Therefore, modern companies need robust digital transformation strategies.

Digital supply chain inventory management and warehousing sector

In today's logistics networks, goods travel in multiple stages from the warehouse to the customer, including delivery and dispatch from the warehouse. Integrating all tasks into single warehouse transactions is important for optimizing product processing steps.

Efficient warehouse operations contribute to cost reduction across the entire supply chain. A company's strategic objectives often revolve around reducing warehousing costs, which is key to improving overall efficiency. In the context of modern supply chains, implementing digital technologies in the warehousing environment brings many benefits, allowing operations to be more efficient.

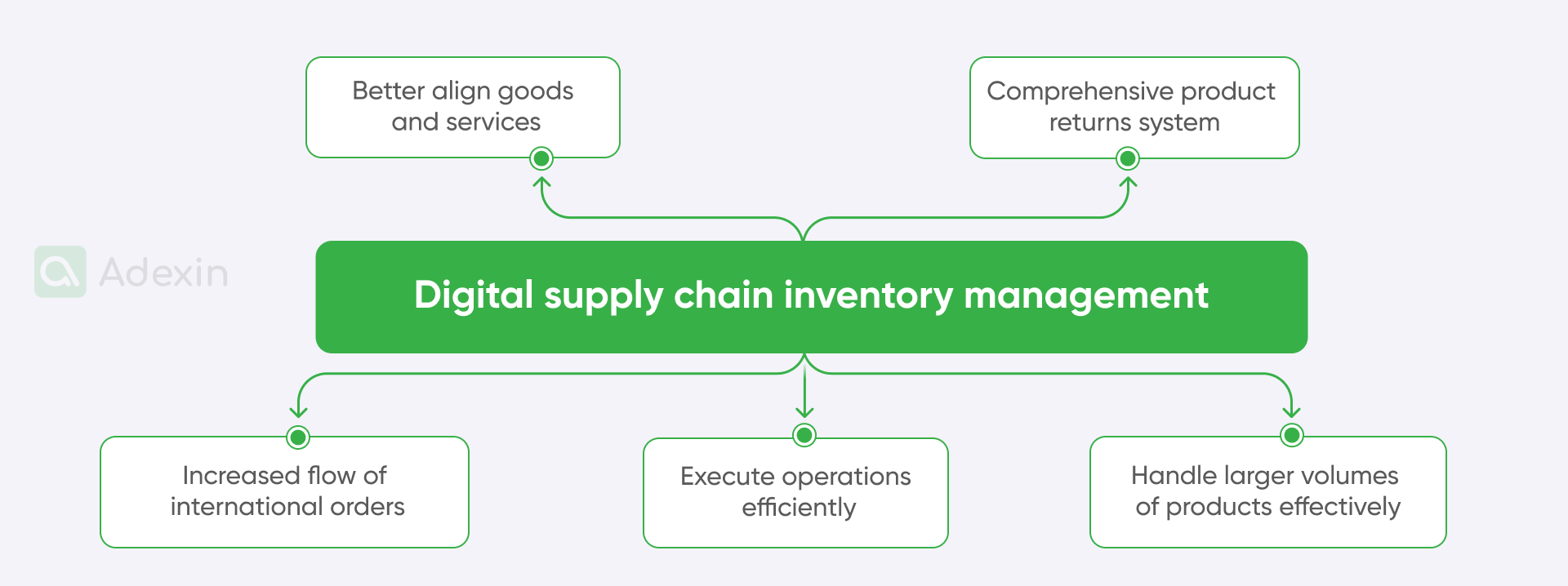

Here are examples of digital transformation in the supply chain and how to get there:

Execute operations efficiently on a smaller scale

Implement task automation and robotics systems, optimizing workflows for faster and more accurate processes. This can include automated picking systems, sorting solutions, and efficient route planning algorithms.

Process and handle larger volumes of products more effectively

Adaptation of advanced warehouse management systems (WMS) that use real-time data and analytics. Using technologies such as RFID and barcode scanning can improve inventory accuracy, while dynamic inventory allocation strategies help optimize storage with various requirements.

Better align goods and services with customer requirements

Integration of customer relationship management (CRM) systems with warehouse operations. Demand forecasting and personalized order processing algorithms can help tailor offerings to specific customer preferences.

Facilitate a more comprehensive product returns system

Implement advanced return system strategies to streamline the reverse logistics process. This can include setting up a dedicated customer returns portal, optimizing return inspection and restocking procedures, and using data analytics to identify recurring product issues.

Manage the increased flow of international orders, both inbound and outbound

Implement a Transport Management System (TMS) and Warehouse Management System (WMS) that helps navigate complex customs regulations and import/export procedures, alongside internal warehouse operations for storage, inbound and outbound (EDI system).

These advances improve operational efficiency and enhance the company's ability to meet customer expectations while optimizing costs across the supply chain.

Digital transformation in warehouse and supply chain operations

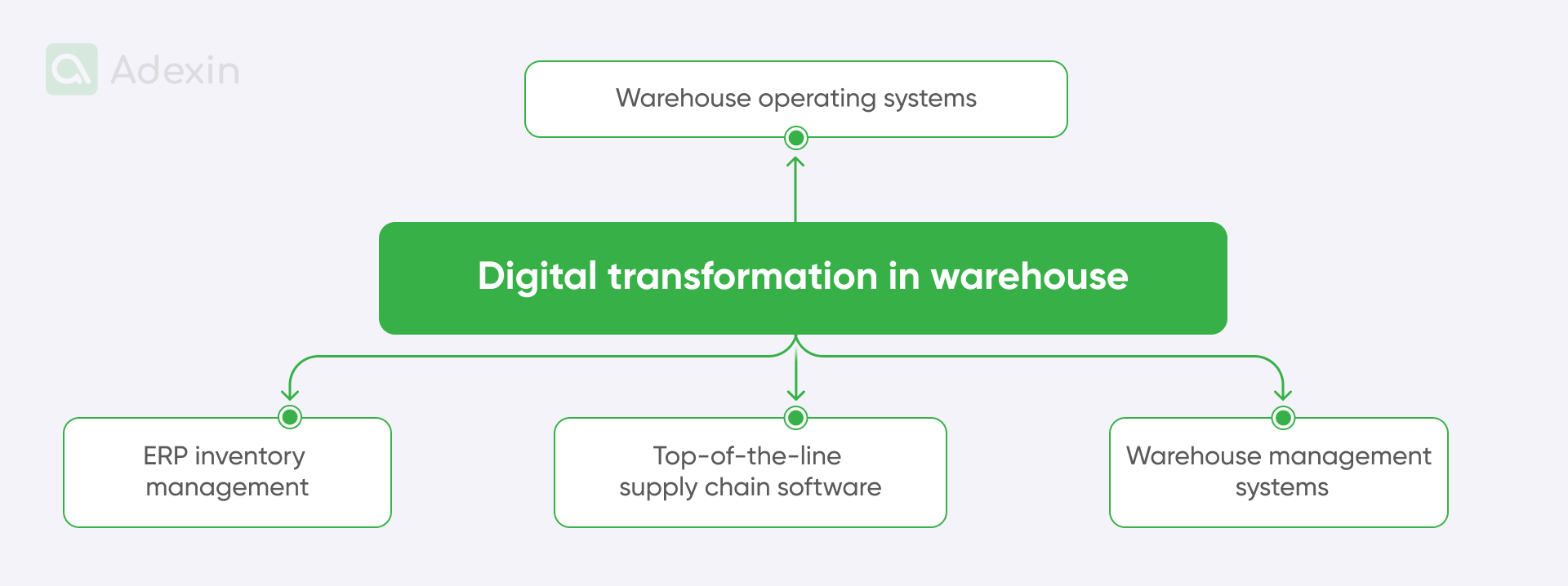

In the high-tech supply chain area, the transformation of supply chain and warehouse operations is driven by a strong emphasis on digitization. This shift toward digitization is changing how companies manage their logistics and inventory. Fundamental to this transformation is a set of new technologies drivers, including:

Warehouse operating systems

Systems have become vital tools for optimizing the flow of goods in warehouses. These systems seamlessly integrate various aspects of warehouse management, from inventory tracking to order processing. They facilitate real-time decision-making, enabling companies to respond quickly to changing requirements.

Top-of-the-line supply chain software solutions (out of the shelf or customized)

The best supply chain software solutions include a range of functions that address different needs in the supply chain ecosystem. These solutions are transformational, streamlining business processes such as demand forecasting, order fulfillment, and freight management. They increase operational efficiency by providing data-driven insights. The solutions are often fully customizable to meet individual operational needs.

Warehouse management systems

Central to the digital transformation in this arena is the Warehouse Management System (WMS), a cornerstone of modern warehouse operations. It orchestrates the movement of goods, optimizing tasks like receiving, storing, picking, and shipping. This integration ensures accurate inventory management, reduces errors, and improves efficiency.

ERP inventory management

The synergy of ERP systems and inventory management modules enables companies to synchronize inventory levels with demand and supply dynamics. This will minimize losses, reduce surplus inventory, and improve resource allocation.

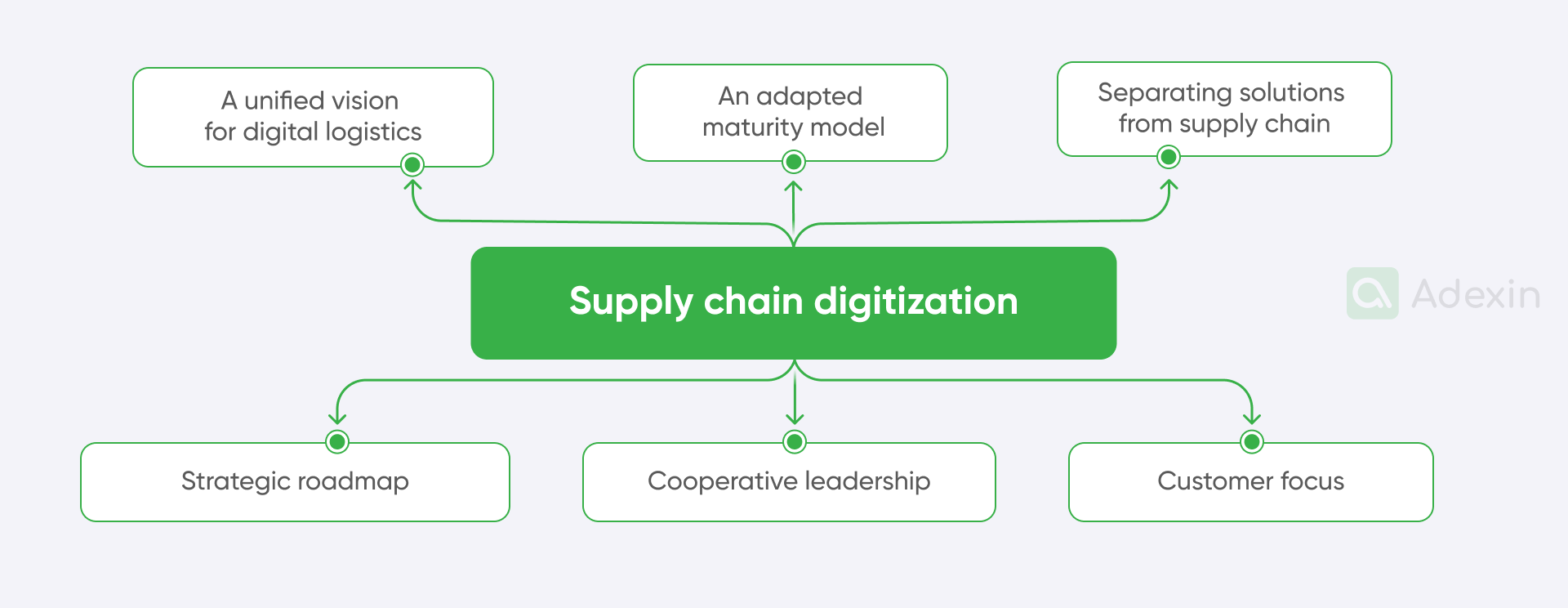

Going forward with supply chain digitization

Exploring the logistics and supply chain digitization field, I noticed that distinctive factors have brought companies to the forefront of this evolution. Here are the steps that help move forward with certain steps in supply chain digitization:

A unified vision for digital logistics

Successful transformation requires a collective understanding of how digital transformation in logistics and supply chains works. This involves recognizing the fundamental shift from traditional practices to knowledge-based strategies, where digitization goes beyond simply automating processes.

An adapted maturity model for logistics

Leadership should develop a maturity model tailored to logistics and supply chain processes, identifying key digitization milestones relating to these areas. Progression should be intentional, developing digital competencies across functional and regional aspects of the supply chain.

Separating solutions from supply chain capabilities

A key lesson is distinguishing between acquiring "solutions" and developing "capabilities" within logistics and supply chain operations. While operational goals are clear, few have systematically considered the digital capabilities required to achieve those goals.

Strategic roadmap for digital transformation

Successful digital transformation in logistics and supply chains requires a strategic roadmap considering core initiatives and complementary technologies. This roadmap ensures the coordinated success of related technology initiatives. You can create a roadmap with your business partner, especially within cross-functional and semi-autonomous logistics operations.

Cooperative leadership

Driving logistics transformation and supply chain digitization requires a collaborative approach. Forming a coalition of representatives from different logistics functions ensures the efficient allocation of resources and a unified vision. You may need to consider choosing a good software partner.

Customer focus in supply chain transformation

In logistics and supply chains, organizations should prioritize capabilities that resonate with customers and differentiate them from competitors, providing a competitive advantage and aligning with business objectives.

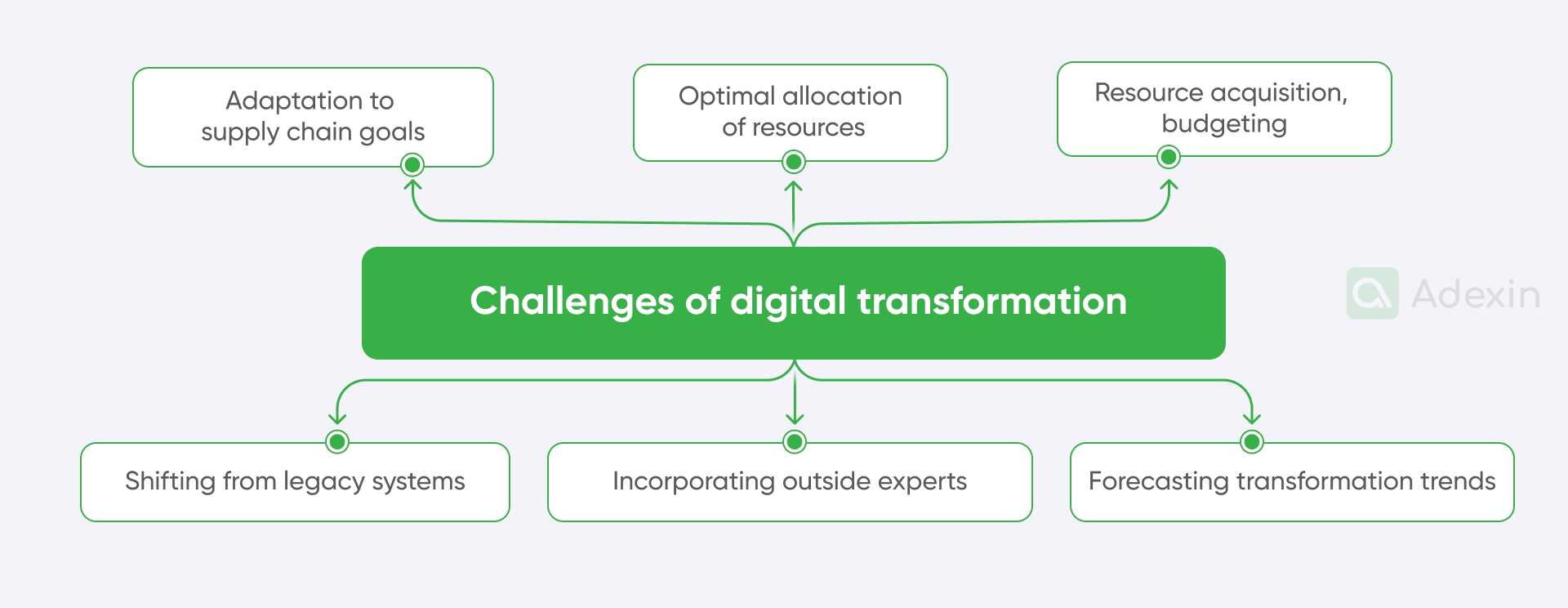

What are the recent challenges of digital transformation?

In the initial part of this article, we touched on some of the challenges. Now, let's delve deeper into how we can outline future trends in warehousing. Moving through digital transformation in the supply chain presents numerous challenges to organizations, demanding strategic foresight and adaptability. However, these barriers can also be transformed into opportunities for growth, innovation, and competitive advantage.

Here are some of the key challenges facing organizations entering their supply chain digital transformation:

Adaptation to supply chain goals in the transportation sector

The success of digital supply chain transformation hinges on closely aligning technological advancements with overarching supply chain goals and key performance indicators (KPIs). If you run supply chain operations, you're involved in the transportation industry, logistics, and warehousing, which requires integration within your internal systems and with systems used by your stakeholders in the supply chain.

A common practice is integrating Electronic Data Interchange (EDI) with your system and carriers. Achieving this balance ensures digital innovations translate into measurable value and tangible results.

Optimal allocation of resources

We all remember situations when crises have occurred. Jobs in lower functions within warehouses became insecure, but the logistics and transportation industries were not as heavily affected. In fact, the demand for truck drivers has increased even during these times. Companies faced challenges due to resource shortages.

At this point, accurately allocating resources to the right transformation areas became paramount. Recognizing these challenges, supply chain companies must prioritize investments that will impact supply chain performance, customer satisfaction, and overall expansion.

Resource acquisition, budgeting, and digital transformation strategy

Digital transformation in the supply chain requires a financial commitment that includes technology, training, and infrastructure. Effectively acquiring these resources while remaining fiscally responsible remains an ongoing challenge.

So, to give you an example, I recall a situation in a warehouse where we lacked resources to implement even basic solutions like mobile devices for order picking. Employees had to collect orders using printed picking lists. This poor condition led to ongoing errors and inaccurate orders. The dilemma is whether to raise your service fees or maintain error-free operations. There's a risk of losing customers in both scenarios, so finding a balance is crucial.

Shifting from legacy systems

Distinguishing between technologies that optimally serve different functional aspects of the supply chain requires rigorous evaluation. Organizations must differentiate between solutions that streamline operations, meet specific requirements, and reduce unnecessary complexity.

Many companies use outdated processes within ERP systems because they avoid upgrading them due to the high costs involved. To cope with the challenge of obsolescence, set aside custom software solutions, such as WMS, FleetMS, and order management systems, to elevate your business operations with new technology.

Need help with warehouse management system development?

Learn how we can boost your logistics processes

Explore moreForecasting transformation trends within robust digital transformation strategies

Staying at the forefront of rapidly changing digital transformation trends and opportunities requires constant vigilance. Organizations must consistently monitor developments to take advantage of emerging innovation opportunities.

Analytics, analytics, and, once more, analytics. This is crucial, and modern custom software development can deliver this quality by integrating various operations into a single source of truth. You can consolidate your data under one roof, like a Control Tower in logistics. Data from all sources allows you to create more adaptive workflows and make informed decisions.

Incorporating outside experts

Being open to sourcing knowledge from outside an organization's industry can bring fresh perspectives and innovative solutions. Organizations using diversity in talent acquisition can leverage unique insights to strengthen their digital expedition.

Why has this become a challenge? Access to knowledge is increasingly difficult due to a shortage of industrial experts and a high demand for SCM and warehousing expertise. Therefore, when deploying a software solution like an ERP system for SMBs, it's crucial to find experts who have experience in custom software development and logistics software development. They should have hands-on experience with supply chain software development projects.

Comprehensive end-to-end transformation is crucial to consider successfully executing a seamless digital transformation across an organization. When you have a warehouse, a distribution center, and a small fleet of trucks, it's not a good idea to focus solely on warehouse operations. Think holistically and also address your fleet management, providing truck drivers with, let's say, truck assistance applications in the trucking industry.

So, the main challenge we're discussing here is to break down silos and cultivate collaboration to ensure a unified and comprehensive approach across all operations.

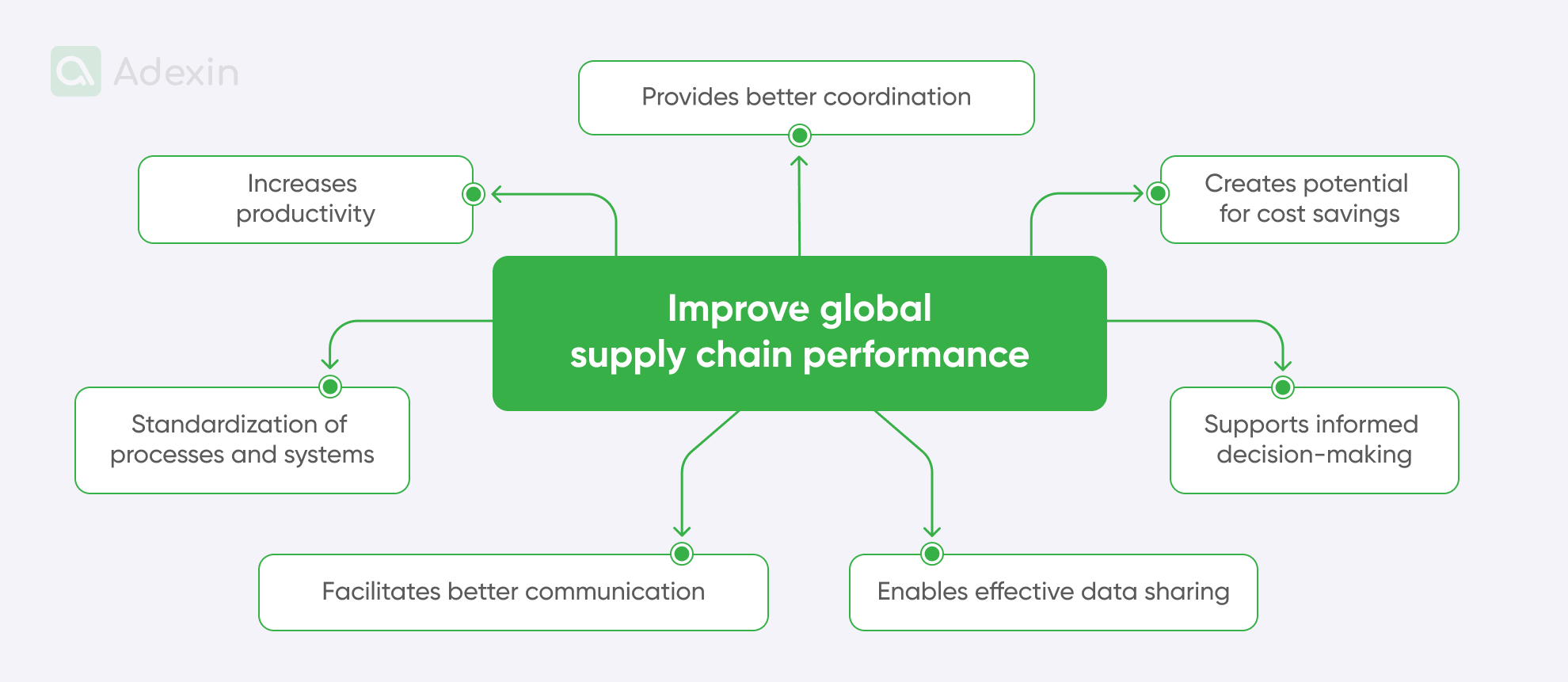

How can we improve global supply chain performance and the warehousing sector?

The most precise illustration of agility is the context of the economic changes resulting from a global pandemic in 2019 and geopolitical disruption in Eastern Europe that occurred since 2022. Real examples of logistics companies able to cope with the global crisis can be found among companies such as UPS SCS, which have managed to adapt to these changes and even increase their economic strength (in 2021, UPS earned US$8.9bn in operating income, up 58% more from the same period in 2020). Collaboration and integration have become indispensable pillars for efficient supply chain management.

Better collaboration between different stakeholders in the supply chain, such as suppliers, manufacturers, distributors, and retailers, brings these values to business:

Provides better coordination. Clear communication channels and real-time updates can support various facilities and extensive networks.

Increases productivity. The company can streamline workflows with maximized resource allocation and reduced bottlenecks.

Creates potential for cost savings. Direct process optimization can focus more on day-to-day operations to reduce overall expenses related to fuel costs, labor costs, which require working hours, etc.

Standardization of processes and systems. Businesses can consider integration with embedded functions of common logistics platforms that unify processes and systems across the supply chain.

Facilitates better communication. Logistics companies can embed digital collaboration tools into their operations to enable transparent information sharing and open communication channels.

Enables effective data sharing. Companies can implement interoperable data formats that secure platforms and data availability while enabling effective sharing.

Supports informed decision-making. Through increased access to accurate and up-to-date data and analytical tools, companies can get automatic updates that support informed decision-making.

Warehouse of the future: What is a smart warehouse?

A smart warehouse is an automated warehouse within a technologically advanced facility in which automatic decisions are made using various forecasting models to optimize operations. These warehouses can quickly adapt to changing customer requirements or processes and offer more flexibility compared to conventional warehouses.

Future trends in warehousing are showing a major shift in technologies, such as blockchain, where operation managers have so-called smart warehouses in their hands. A smart warehouse is actually the concept of the future setup for today’s warehouses.

It includes technologies such as:

Internet of Things: Connecting devices and software, it gives warehouse operations remote control to operate daily (for example, IoT can connect sensors and RFID and provide data to ERPs).

Robotics: Warehouses are facilitated with autonomous vehicles that can independently deliver goods from docks to stock and vice versa.

Big Data Analytics: This technological advancement helps collect data from all areas in the warehouse, making all operations planned more accurately.

Digital Twin: This is one of the best digital warehouse solutions for predictive analysis, which can create an entire warehouse layout in a simulated environment.

Drones: Flying equipment is used to control stock levels, perform inventory cycle counting, and check inaccessible locations on higher shelf levels.

Blockchain: This digital software technology secures internal transactions, becoming most adapted for financial transactions but also could replace EDI protocols in the future.

Implementing a smart warehouse comes with higher installation costs, a time-consuming transition process, and the need for strong management support. So, this is not an easy task as a whole. Today's automated warehouses are often known for the use of AGV equipment, such as palletizing robots, carton flow racks, rotary storage cabinets, and storage and retrieval machines. More recently, they have been used by UPS, which also places great emphasis on automated storage and material flow mechanisms that are a key element of an automated warehouse or distribution center. An example of this is the UPS SCS warehouse in Redmond, in the Netherlands.

Are you in search of a reliable tech partner?

Adexin can help with advanced logistics solutions

Contact usFinal takeaway digital transformation efforts

Digital technologies have ushered in a new era of increased efficiency in warehouse operations, resulting in an overall increase in supply chain performance. Analyzing the implications of digitization on the complexities of warehousing in the supply chain management field, we highlight aspects such as warehouse management systems (WMS) and others.

The infusion of digital solutions has transformed the supply chain management landscape, fundamentally changing its outlines at the center of this shift in warehousing, which functions at the center of distribution and inventory management within the vast supply chain ecosystem.