Most modern success stories in logistics now emerge from a powerful mix of artificial intelligence, automation, sustainability, cybersecurity, and data-driven strategy. By 2026, logistics leaders will no longer compete only on speed and cost, they will compete on resilience, digital maturity, carbon reduction, and real-time visibility across the entire supply chain.

This article presents 5 real-world logistics management examples in 2026 that demonstrate how global companies are using AI-driven forecasting, robotics, digital twins, green logistics, and predictive analytics to stay competitive in an increasingly volatile market.

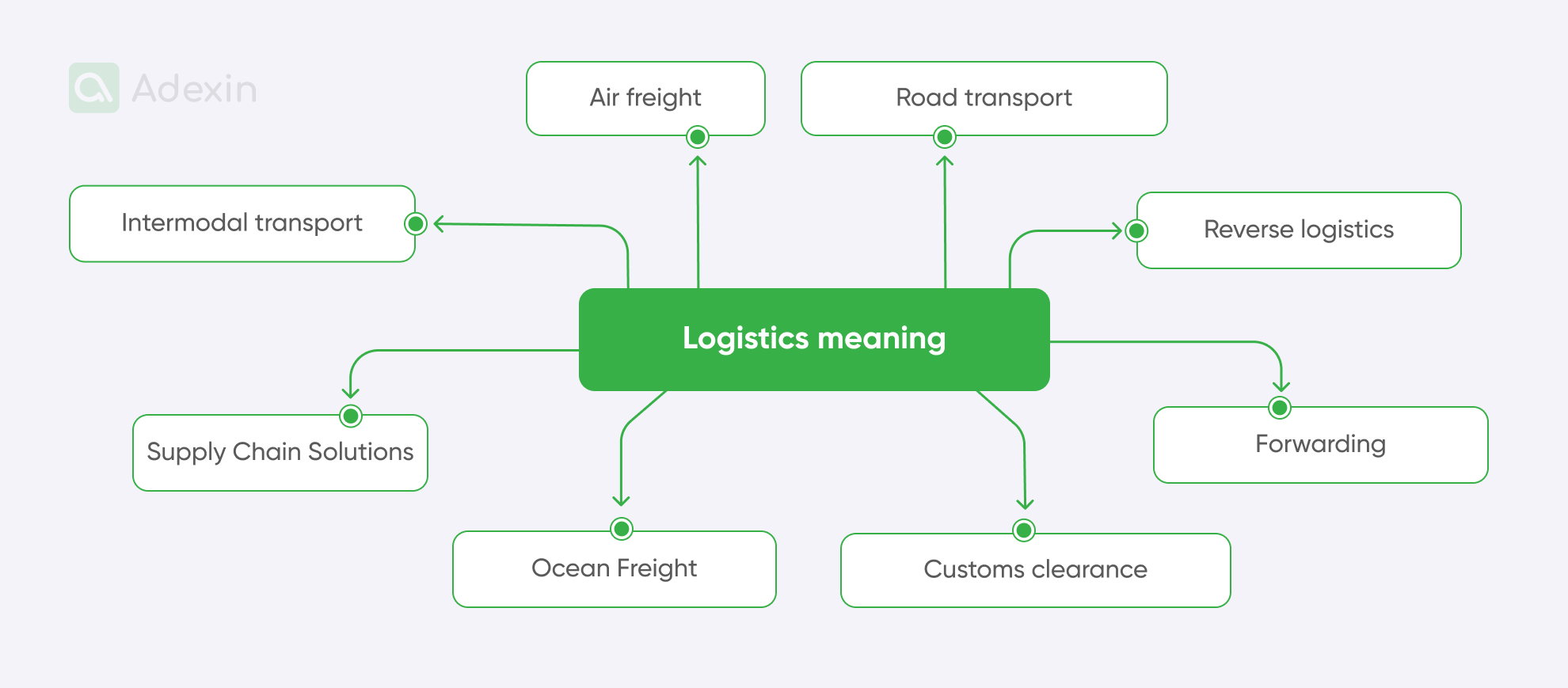

Logistics meaning with management example

Logistics is a complex process that concentrates on warehouse and inventory management to plan warehouse space and take care of all transportation means. The last one can cover intralogistics and road freight. The subject of logistics is also deeply tied to technology development, such as blockchain in supply chain management, digital twin, and other business logistics processes.

A great example of logistics' meaning can be given by some companies that complete the picture of this vibrant landscape with various modalities. So, the best idea is to provide you with a logistics management example of an existing company that operates in multiple industries. To be most accurate, we can give an example of a business with fulfillment services.

A modern example of a global logistics company is UPS (United Parcel Service), which, by 2026, will operate as a fully AI-driven logistics ecosystem. Founded in 1907, UPS today delivers tens of millions of parcels daily in over 220 countries and territories, with advanced automation embedded across its entire network.

UPS has transformed its operations using:

AI-based demand forecasting,

autonomous sorting hubs,

predictive maintenance for fleet management,

and carbon-optimized routing for last-mile delivery

One of the most significant competitive advantages of UPS in 2026 is its use of AI-powered one-day and same-day delivery optimization, enabled by digital twins of its hubs and city logistics networks. This allows UPS to dynamically reshape delivery routes in real time based on traffic, weather, and carbon impact.

Here are examples of logistics that UPS operates in:

Intermodal transport. The way of transport that mixes rail, road, and sea for efficient movement of goods, optimizing costs and transit times.

Air freight. Fast and reliable air transport for urgent deliveries, including overnight and temperature-controlled services.

Road transport. This is a comprehensive road transport solution for domestic and international shipments, including LTL and FTL options.

Forwarding. This area concerns the management of global freight logistics, handling customs, documentation, and cargo insurance for hassle-free international shipping.

Supply chain solutions. UPS SCS offers extensive management services, including logistics, distribution, inventory optimization, and industry-specific solutions, such as healthcare and retail logistics.

Ocean freight. UPS customers can get cost-effective international ocean transportation services using full-container-load (FCL) and less-than-container-load (LCL) services.

Customs clearance. UPS often uses external companies to handle customs, but it also has a substantial department worldwide to handle customs issues. This one assists with import/export compliance, document handling, import duties, and regulatory compliance.

Reverse logistics. UPS efficiently manages returns, product recalls, recycling, and waste management.

Naturally, UPS has many competitors these days, and domestically, they are the US Postal Service (USPS) and Federal Express (FedEx). Stronger competition is even internationally, where companies such as DHL, TNT NV, Royal Mail, and Japan Post are trying to push UPS from its dominant position.

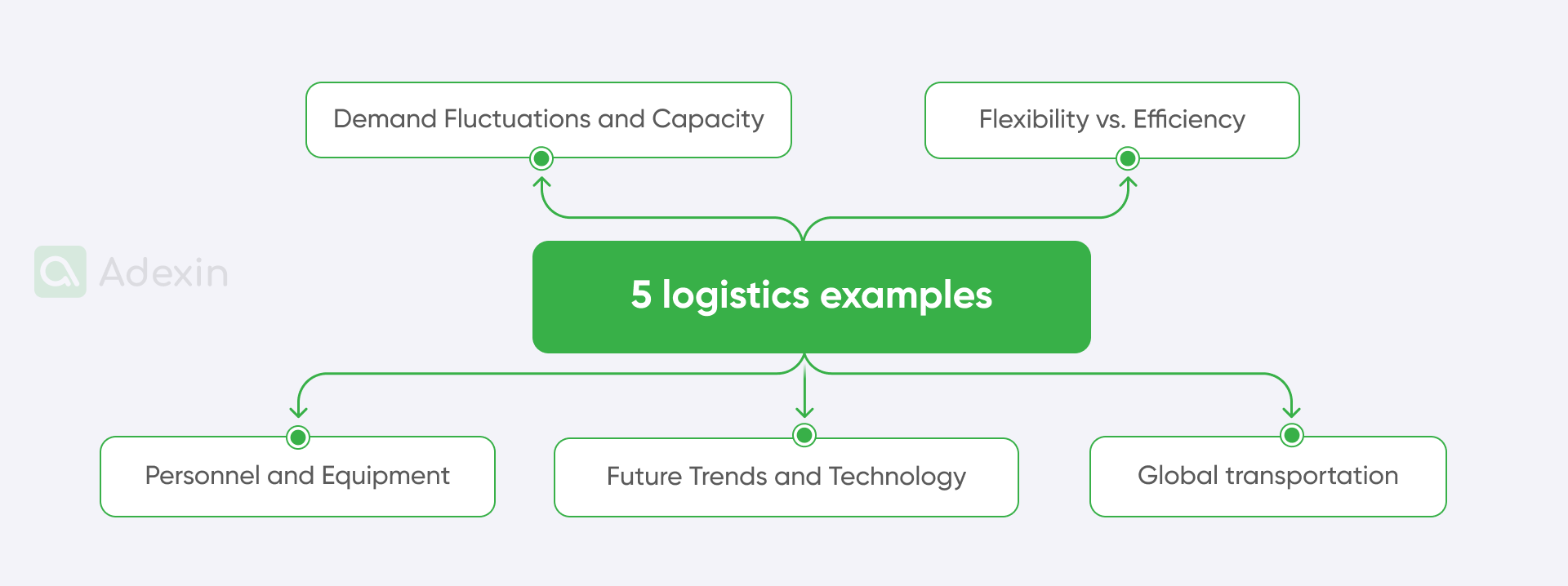

Real-world case studies: 5 logistics management examples

In the post-pandemic and post-geopolitical-shock era, UPS shifted its strategic focus from crisis-driven healthcare logistics to full-scale supply chain resilience. By 2026, the company will have restructured its global network around nearshoring, regional distribution hubs, and AI-based risk forecasting to withstand geopolitical tensions, port congestion, and climate disruptions.

Beyond UPS, we can call 5 other strong logistics management examples that, in addition to their core parcel delivery services, can expand your knowledge about logistics strategies and management. Below are 5 short case studies to get insights into logistics strategy, technology adaptation, and the ability to shift operations.

We set up several problems that occurred in the logistics and explained how businesses tackled them with real-life examples.

1. Demand fluctuations and capacity with supply chain management

Logistics companies, most of the time, struggle with fluctuations. Decreasing demand for one product cannot be compensated by rising demand for another. From this aspect, we can conclude the following: demand for products can fluctuate, creating challenges for internal logistics management (e.g., trucks, staff).

An excellent approach to solving these issues is fostering long-term relationships with clients. We have observed this based on XPO Logistics, a company from the US. By offering a range of contract lengths and adaptable solutions, the company caters to changing market conditions and evolving client requirements while fostering long-term partnerships and customer satisfaction.

In 2026, XPO will have additionally implemented AI-driven demand sensing and real-time labor optimization. These systems dynamically predict volume peaks up to 14 days in advance and automatically adapt staffing, warehouse capacity, and trucking schedules without manual intervention.

2. Flexibility vs. efficiency in the global supply chain

Companies often keep their logistics management in-house to maintain direct customer contact and respond to changing customer demand planning. This creates control in management and limited flexibility but helps maintain efficiency. Here is the challenge posed by this approach: Finding a balance for internal management that allows for direct customer interaction and quicker response to changing needs without losing efficiency.

A logistics management example of FedEx successfully handling this issue shows how the company adapted, though many others have faced similar challenges. By 2026, FedEx will have integrated autonomous delivery pilots, drone-based last-mile services in rural regions, and AI-powered carbon-aware routing, allowing the company to balance flexibility, profitability, and ESG compliance simultaneously.

3. Personnel and equipment for effective logistics management

The availability of personnel and equipment in a company conducting logistics activities in-house entails responsibility for personnel matters such as recruitment, selection, and training. Sufficient equipment must be available for any necessary repairs. Companies face this challenge: At a certain point, In-house logistics require managing personnel (recruitment, training) and equipment maintenance. This requires upfront investment in logistics infrastructure to prevent failures in equipment and all business processes.

An excellent example of how these issues are handled is DHL. They outsourced logistics management, which was quite a relief for the company and allowed for overhead cost reduction. They identified that different customers have varying needs by industry, enabling them to deploy a more suitable logistics management model for each facility.

In 2026, DHL’s strategy will have evolved into “smart outsourcing,” where human resources, robotics, and AI orchestration work together. Outsourcing is no longer only about cost reduction, it is about scalability, cyber-resilience, data sovereignty, and automation readiness across regions.

4. Future trends and technology through automation and inventory management

The impact of emerging trends and concepts is now heavily focused on technology in logistics methods. The high-tech industry has brought changes to different sectors of the logistics industry. These trends are expected to influence many major changes over time. The major challenge here is: Technology adaptation for various logistics modes, including warehouse automation, intralogistics, and energy efficiency.

DSV from Denmark sets an example of a logistics management that has handled this challenge. They initially created their own DSV fulfillment factory with a significant investment in automation in a single facility. By establishing a modernized center as a testing and development site, they expanded automation adaptation to other facilities. DSV has fostered technology and adapted trends as an early adopter of technology in small areas of its operations.

In 2026, DSV extended this approach by introducing full digital twins of warehouses and transport corridors. These virtual environments allow real-time simulation of capacity, energy consumption, labor demand, and congestion, reducing operational risks before physical execution.

5. Global transportation and logistics management

Everything is becoming increasingly expensive, and global transportation is no exception. When we need to ship quickly, we typically use air freight, which has become more expensive due to environmental considerations. Transportation costs are among the top challenges facing the freight logistics industry, as they constitute one of its primary expenses. Global transportation has become a pressing issue. Here is the defined challenge: Air freight has become highly expensive and has faced significant international criticism due to the lack of green policies for air shipping, which affects the brand image and leads to lower shipping volumes.

A good management example is KLM Cargo, which has implemented sustainable transportation models for air cargo and fuels to lower its carbon footprint. In 2026, KLM Cargo will operate under a multi-layered green aviation strategy that includes sustainable aviation fuel (SAF), AI-based fuel optimization, carbon-aware pricing models, and digital emissions reporting for enterprise clients. These measures not only reduce environmental impact but also directly influence large corporate customers’ supplier selection processes.

Below are some good examples of how to deal with the latest challenges in the logistics industry. The main lesson for small and medium-sized companies is that no logistics challenges can be overcome. We've given you a glimpse of how it works. In the next part of this article, we will reveal how companies can truly achieve their business goals by positioning themselves effectively in the market.

Top 10 examples of logistics technology for effective management

In 2026, traditional logistics software is being replaced by autonomous digital ecosystems powered by artificial intelligence, digital twins, and real-time risk engines. The most critical logistics technologies today include:

AI agents for autonomous supply chain decision-making

Digital twins of warehouses, fleets, and ports

Predictive risk and disruption engines

Blockchain 2.0 for trusted cross-border documentation

Cyber-resilient logistics platforms

Autonomous transport and robotic fulfillment

Carbon intelligence and ESG reporting systems

Real-time multimodal control towers

Autonomous TMS and WMS platforms

Supply chain data lakes for predictive analytics

There are several ways to leverage technology in logistics. One of the best approaches is to learn from others' experiences. Fortunately, plenty of high-tech developments currently available on the market can be utilized in your logistics management.

Let's explore together what is worth considering:

1. Warehouse automation for accurate inventory control

Many logistics companies like Amazon and Alibaba have implemented advanced robotics and automated systems in their warehouses, such as autonomous vehicles. These technologies help optimize inventory management, order picking, and packing processes, improving efficiency and reducing operating costs.

2. Route optimization software for efficient routes

Companies such as UPS and FedEx use sophisticated route optimization software. These systems analyze various factors, such as traffic patterns, delivery locations, and package sizes, to determine the most efficient delivery routes. This reduces fuel consumption and emissions and increases delivery speed and customer satisfaction. Very often, these companies build logistics management software tailored specifically to their needs.

3. Tracking and monitoring using IoT for logistics service

IoT (Internet of Things) devices are increasingly used in logistics management to track shipments in real-time. These devices provide precise location data, monitor environmental conditions (such as temperature and humidity in the case of perishable goods, in other words, FMCG), and alert logistics managers to any potential problems or delays. This technology provides better visibility and control over the supply chain, leading to better decision-making and customer service.

4. Transportation management for more effective logistics

Transportation management systems (TMS), provided by companies like Oracle, SAP, and IFS, are used to manage freight. These systems help in managing and optimizing freight movements, carrier selection, and freight costs. However, relying on large logistics management software providers may not always meet the specific needs crucial to your business. Opting for a custom-built TMS system tailored to your business requirements can provide the same affordability as off-the-shelf solutions while ensuring it addresses your unique operational needs effectively.

Need help with transport management systems development?

We are happy to assist you

Explore more5. Fleet management system for better customer experience

Fleet management systems (FleetMS) are used to track and manage fleets of vehicles. These systems provide real-time monitoring of vehicle locations, maintenance schedules, driver behavior, and fuel consumption, helping to optimize fleet operations and reduce costs. Implementing a comprehensive FleetMS that covers all transportation modalities can be challenging, especially in highly saturated transportation environments. Customized FMS solutions can address specific needs such as loading and route planning, ensuring efficient and effective fleet management.

6. Supply chain control tower to reduce costs

Supply chain control towers integrate data from various sources across the supply chain to provide real-time visibility and control. Examples include SAP's Supply Chain Control Tower and Oracle's Supply Chain Management Cloud. These platforms enable proactive management of supply chain disruptions, inventory levels, and demand forecasting. SCCT systems can be complex, and we highly recommend getting a custom SCCT system rather than an off-the-shelf one.

7. Enterprise resource planning system

Enterprise resource planning systems (ERP), such as SAP ERP, Oracle ERP Cloud, or Microsoft Dynamics 365, integrate and manage core business processes across an organization. In logistics, ERP systems can operate as inventory management software, procurement, finance, and customer service operations, providing a unified platform for data management and decision-making. If you have small and medium-sized businesses, you can get a custom ERP system developed at a lower fee than purchasing one from the market.

8. Document management system for better quality control

Document management systems, such as MS SharePoint, are used to digitize and organize documents related to logistics operations. These systems facilitate efficient storage, retrieval, and sharing of shipping documents, ensuring compliance with regulatory requirements and improving team collaboration. In any case of need, you may need your DMS system only for POD or invoice management. Both instances are characteristics of SMBs. Here, you can also benefit from custom DMS system development.

We have successfully implemented a DMS system at one of our clients. In this case, the implementation enhances the quality of shipping document management with built-in security and compliance features that enable on-time document generation and digital document flow through all departments. This solution also provides a competitive advantage as it improves network management.

9. Warehouse management system to improve logistics processes

WMS software manages warehouse operations, such as Warehouse Management from Manhattan Associates or Blue Yonder (formerly JDA Software). Warehouse management systems optimize inventory storage, picking, packing, and shipping processes, improving warehouse efficiency and accuracy. You can also get your modern WMS system tailored to your business needs.

10. Order management system to gain a competitive edge

OMS platforms, such as IBM Sterling Order Management or Salesforce Order Management, streamline order processing and fulfillment. These systems manage orders from receipt to delivery, optimizing order routing, inventory allocation, and customer service, increasing overall order management efficiency. Custom OMS systems can guarantee more efficiency and remain more cost-effective.

Are you in search of a reliable tech partner?

Adexin can help with advanced logistics solutions

Contact usSummary on logistics management

In 2026, logistics management will have entered an autonomous, AI-driven, and sustainability-centered era. The combination of artificial intelligence, digital twins, cyber-resilient infrastructure, robotics, ESG-driven operations, and predictive analytics defines the new standard of global logistics excellence.

Leading companies such as UPS, XPO Logistics, FedEx, DHL, DSV, and KLM Cargo prove that competitive advantage now depends not only on speed and cost but on real-time visibility, environmental accountability, geopolitical resilience, and automation maturity.

Businesses that fail to modernize their logistics architecture risk losing efficiency, profitability, and market relevance. Custom-built digital logistics ecosystems, tailored to individual business models, are becoming the dominant strategy for companies that seek long-term scalability and resilience.