The world of supply chains is evolving, and with it come the demands on businesses. No longer is it enough to simply move goods from point A to point B efficiently and further down the road without optimization of freight cost? Today, companies face intense pressure to operate sustainably. This is an ethical duty, and everyone has an eye toward future disruptions. This shift is highlighted by a significant trend, in 2021, 29% of companies incorporated environmental, social, and governance (ESG) metrics into their employee incentive plans, a 7-percentage-point jump from the previous year, with an indication to grow further by 2025. This isn't just about good corporate citizenship, it's about mitigating reputational, regulatory, and financial risks.

Consider the example of Henkel, which doesn't know them. This company understands and has demonstrated the tangible benefits of intense environmental action. Over a decade, their sustainability initiatives have led to a 40% reduction in energy consumption and a 20% decrease in waste. These impressive results weren't achieved by chance. They leveraged advanced strategies like a digital twin that connects and benchmarks 30 factories, providing real-time insights for optimization.

This proactive approach to sustainability is cleverly combined with innovative technological adoption. This underscores a critical lesson – robust supply chain monitoring is far from a mere operational task. For us, supply chain software development experts, it is a strategic imperative that drives resilience and competitive advantage. In this article, we'll tell you all about how to achieve this level of monitoring.

What is supply chain monitoring, and why is it important?

At its core, supply chain monitoring is the continuous oversight and analysis of all activities, supply chain processes, and performance indicators within a supply chain. It aims to ensure efficiency, identify potential risks, and drive continuous improvement. It is a comprehensive health check for your supply network, providing real-time visibility and actionable insights.

This fact-based approach considers the resources needed to create a product, including labor costs, freight costs, service rate, gross profit percentage, and even machine productivity (aiming for metrics such as >80% equipment efficiency), as well as material spending and production impact. Using data, companies can achieve greater cost reductions, often as much as -18% compared to the conventional range of -50% to -30%, while promoting shipping costs transparency and collaboration.

For someone like Maria, a transportation costs manager, the ability to monitor her freight cost and fleet's fuel efficiency in real time instantly flags deviations. For her, this is a game-changer. It's not just about cost savings and gross margin return, it's about minimizing her department's carbon footprint and aligning with company-wide ESG goals.

Similarly, a business analyst, David, relies on integrated supply chain data to identify potential bottlenecks before they escalate, like those in physical inventory management. He uses advanced analytics to predict demand fluctuations and proactively advises on average inventory turnover adjustments. This allows him to shape demand and enhance labor planning, ensuring that even unforeseen events have minimal impact on damage-free delivery schedules.

These personal stories highlight how effective supply chain metrics empower individuals and departments to make data-driven decisions that contribute to larger organizational goals. We use them to prove that a focus on advanced analytics and sustainability isn't just good for the planet, it's good for business.

A three-level look at key supply chain issues

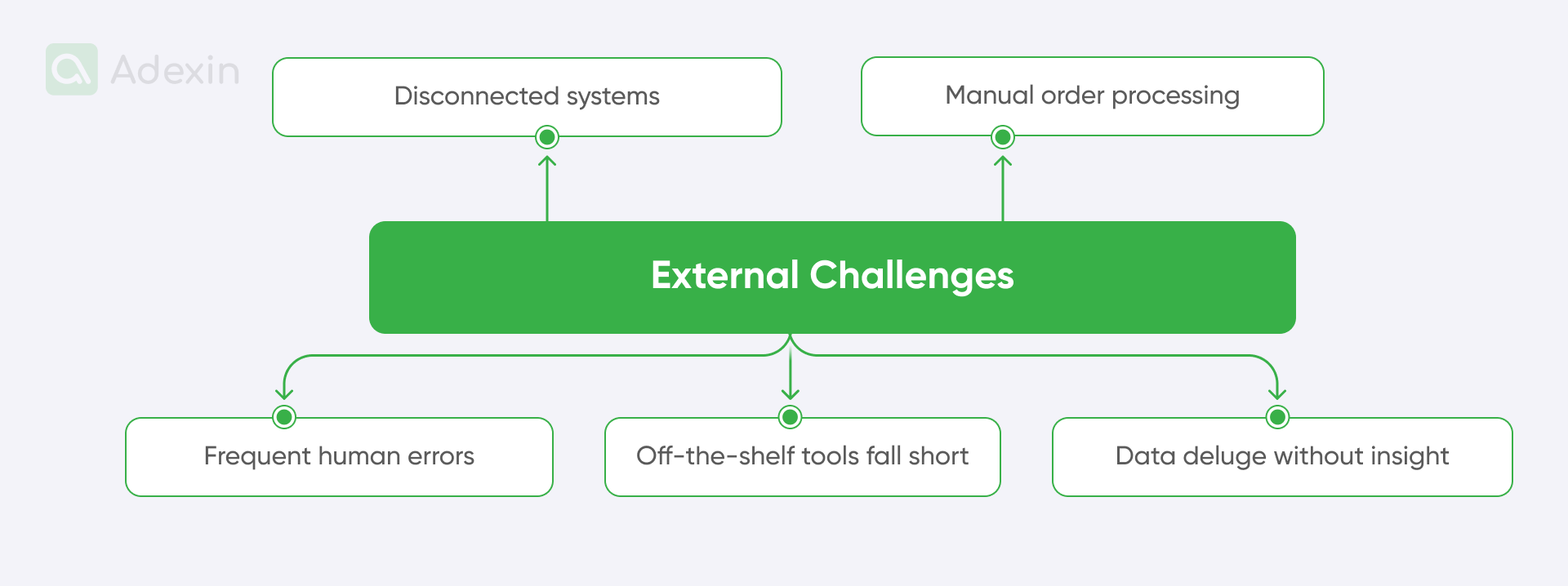

While an essential source of competitive advantage, supply chain management is fraught with complexities and challenges. These problems arise from the rapidly evolving corporate environment and often manifest at three interrelated levels: external, internal, and philosophical.

Many organizations grapple with fundamental structural and operational hurdles at the external level:

Disconnected systems. We often see warehouse management systems (WMS), transportation management systems (TMS), and enterprise resource planning (ERP) platforms that simply don't talk to each other.

Manual order processing and slow workflows. This fragmentation leads to bottlenecks, inefficiencies, and bogging down operations.

Frequent human errors. These cumbersome, disjointed processes inevitably result in mistakes.

Off-the-shelf tools fall short. Despite their promises, generic tools often fail to address the unique needs of individual businesses.

Data deluge without insight. While the explosion of data from sources like IoT is promising, it often exacerbates issues when not effectively managed, leading to a flood of information without actionable insights.

Supply chain efficiency can be calculated only with key performance indicators (KPIs) to avoid a lack of metric measures for supply chain performance.

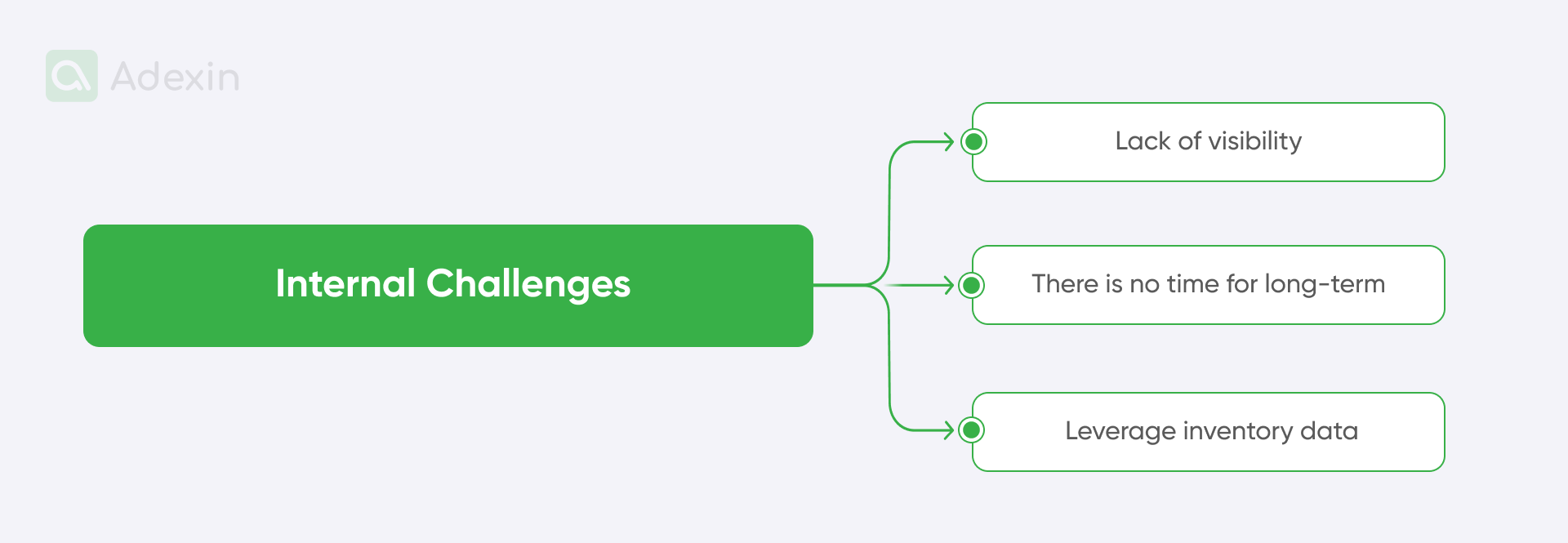

Internally, these external issues cascade into a series of managerial difficulties:

Lack of visibility. A profound oversight across the supply chain forces teams to engage in constant reactive management.

There is no time for long-term planning. This perpetual firefighting creates pressure on staff, leaving little opportunity for strategic development.

Inability to leverage inventory data. We struggle to effectively access, use, and appropriately analyze the ever-increasing amount of available data, a critical internal roadblock hindering efficient and effective supply chain operations.

Finally, these daily frustrations coalesce into a pervasive philosophical question that haunts many in the industry. So, I'm asking you today, why does logistics still feel stuck in 2005, even though it's 2025?

Despite significant technological advancements and the clear benefits outlined by Industry 4.0 concepts such as automation, artificial intelligence, blockchain, and big data analytics, many organizations struggle to fully leverage these innovations.

We should somehow bridge the gap between tech and reality. The broader adoption needed to transform supply chains into resilient, flexible, and truly modern operations remains a significant hurdle. This philosophical disconnect between available technology and current operational reality underscores the need for a fundamental shift in how supply chain metrics are approached.

Exploring supply chain monitoring through the case studies experience

Supply chain monitoring tools are advanced technological solutions that provide real-time visibility, enhance decision-making, and streamline operations across the supply chain. They transform traditional, reactive logistics into a proactive and highly efficient system.

Modern supply chain metrics tools revolutionize logistics by offering key features that dramatically improve efficiency and responsiveness. First, they enable the automation of basic decision-making actions. Monitoring helps handle routine tasks to boost efficiency and accelerate response times.

This advanced cloud software leverages real-time data and automation to optimize transportation assets, demonstrating Adexin's ability to not only understand but also enhance complex operational workflows with bespoke solutions.

By the second, these tools leverage AI for real-time data insight. So, for example, machine learning sifts through vast amounts of information, like weather reports and port dwell times. All that to anticipate delays and provide actionable insights. Truly effective visibility tools must harness AI to enhance operational capabilities, but not as the best solution.

Adexin, an expert in logistics and supply chain, perfectly integrates into the client's processes, delivering completely custom solutions tailored to specific needs. Let's see below the two customer cases from us:

eProcurement solution for educational resources

ITS Astra’s order management system (OMS), developed by Adexin, demonstrates how monitoring tools streamline complex procurement processes for educational resources. This system allows for processing inquiries for hundreds of inventory items in minutes instead of days, provides full transparency on logistics and the supply chain for delivery managers, and enables a 100% reduction in paper usage and automated and accurate documentation flow along with inventory turnover ratio velocity. Over two years, it has enabled ITS Astra to significantly scale transactions without sacrificing quality.

It has also helped eliminate paper catalogs and manual Excel usage for school employees and procurement agency managers, and simplified principal budget control and approvals.

AI-powered parking management system

Adexin and 6sense Innovations collaborated on an AI-powered parking management system that showcases how real-time data and automation optimize transportation assets. This advanced cloud software leverages computer vision and AI to process around 100,000 cars and related transactions daily, helping parking businesses increase revenue up to 10 times and lower operational costs and investments by up to 90%. This is how to get the inventory turnover ratio.

By providing real-time data on parking space loading, it allows for immediate optimization in response to increased customer demand, saving resources and enhancing the user experience for the hundreds of car parks in Scandinavia, the Baltic, and Central Europe that currently use 6sense Innovations solutions.

Need help with custom software development for your supply chain business?

Learn how we can help you

Explore moreSolution pathways for effective supply chain monitoring

Going further down the road, achieving excellent supply chain metrics requires a strategic approach to technology deployment. While the challenges in modern logistics are multifaceted, solutions can be tailored to an organization's specific needs and existing infrastructure.

Let's take a look at solution paths that improve supply chain performance and ensure robust monitoring:

Leveraging existing solutions for the entire supply chain

This approach involves the rapid integration of off-the-shelf warehouse management systems (WMS), transportation management systems (TMS), and business intelligence (BI) tools. This path prioritizes speed and ease of deployment. It often involves plug-and-play configurations where readily available software is adopted with minimal customization.

Among the advantages fastest time to implement, lower initial development costs, and leveraging established features and community support. Among the disadvantages is that it may not perfectly fit unique business needs, leading to workarounds, limited flexibility for highly specialized processes, potential for vendor lock-in, and stock availability limitation or excess inventory turnover.

Using hybrid solutions across the entire supply chain

A hybrid solution combines the benefits of existing, robust platforms with tailored custom modules to address specific organizational requirements. This path involves integrating entire processes of off-the-shelf components, for example, a commercial ERP system or a standard dashboard with custom-built modules, for example, a proprietary routing engine, a specialized analytics module, or a unique vendor portal.

Among the advantages, balances speed of deployment with customization, addresses unique operational needs without rebuilding an entire system, potentially more cost-effective than fully custom for specific scenarios, like on-time actual delivery date of the entire inventory turnover. Among the disadvantages, integration complexity can be significant and difficult to fill the rate of investment return, requires expertise in both commercial software and custom development, and ongoing maintenance can be challenging across disparate systems.

In addition to leveraging existing solutions and hybrid approaches, completely custom solutions offer an alternative for organizations with highly unique or complex supply chain requirements. These solutions are built from the ground up to precisely match an organization's operational workflows, data integration needs, and long-term strategic goals.

Adexin specializes in delivering such custom supply chain monitoring tools. By deeply understanding a client's specific challenges and objectives, Adexin designs and develops bespoke software that offers unparalleled flexibility, scalability, and integration capabilities, ensuring a perfect fit and maximizing operational efficiency.

Why modernization is no longer optional

Well, it's the reality we've soft orders delivered for companies like S1Seven, ITS Astra, 6sense Innovations, and eTEU. With the right supply chain monitoring tools, your future can include dispatchers getting real-time status on one screen, providing immediate oversight. Supply chain managers receive automated alerts when something goes wrong, enabling proactive problem-solving.

Delaying the modernization of your supply chain monitoring isn't just standing still, it's falling behind. Sticking with outdated methods means:

Continuing to rely on Excel leads to delays and penalties, as processes remain prone to human error and lack real-time insights. You may get higher supply chain costs and stock outages.

Uncoordinated processes result in wasted inventory investment and wasted logistics costs, often adding 1,5-2 times to your total supply chain costs.

Implementing wrong-fit software creates another patchwork mess, failing to address core issues, and adding more complexity to your operations.

Achieving success in modern supply chain metrics hinges on several key factors, including real-time visibility, operational optimization, improve customer satisfaction, increased agility, and data-driven decision-making. So, what we’re saying, that this transformation fosters stronger customer satisfaction relationships and builds a more resilient and adaptable supply chain. You can truly rely on it and get what ultimately drives continuous improvement and a competitive edge.

Are you in search of a reliable tech partner?

Adexin can help with advanced logistics solutions

Contact usFinal takeaway

The personal stories and case studies presented here underscore a critical truth. This is saying that effective supply chain monitoring is no longer a luxury but a necessity for competitive advantage. Well, with no doubt, we truly agree with that. From proactively managing inventory turnover and optimizing labor to streamlining complex procurement and revolutionizing parking management, all say that the power of real-time data and advanced supply chain analytics is undeniable.

Let's connect and get ready to elevate your supply chain performance. We draft a technical approach and timeline. See more of our case studies to see where we've helped companies like yours and ensured customer satisfaction for years.