Companies in the supply chain are now focused on taking steps towards critical technological advances that will enable their business with autonomous operations. There is a significant emphasis on self-driving vehicles, which, in fact, support logistics and transportation solutions. When we consider the supply chain context, the application of self-guided vehicles (SGV) is an ongoing trend affirmed by many of today's companies. Nearly half of the respondents in the latest report from The Business Continuity Institute (BCI) from the UK have confirmed that they are transitioning their business operations to become autonomous by 2035.

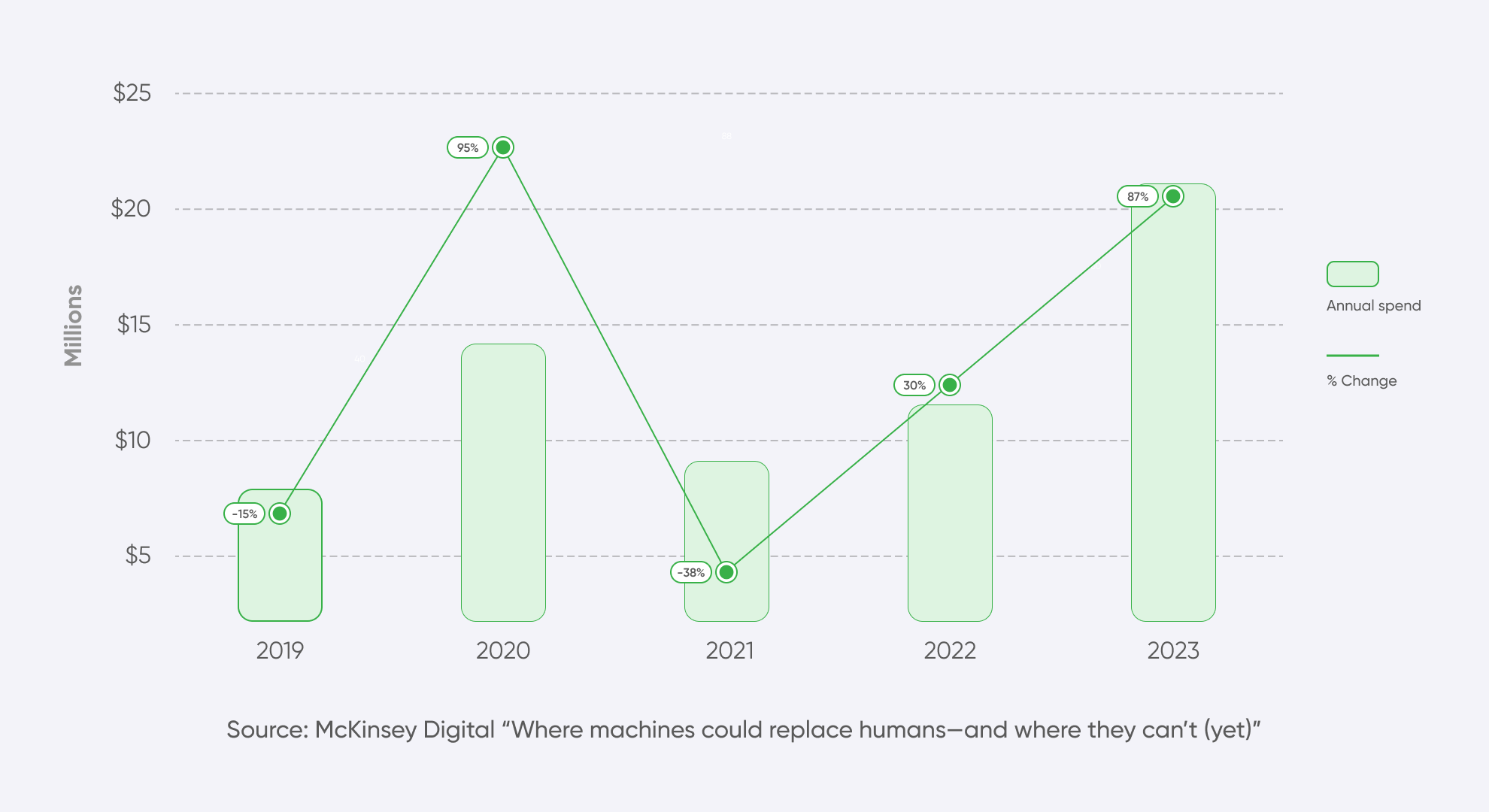

Supply chain leaders' investment in innovation exceeds 74% in 2023

Researchers at McKinsey analyzed over 2,000 work activities spanning more than 800 occupations. The study examined the time allocated to specific tasks and evaluated the potential for automating these activities.

The statement from McKinsey clearly shows that there is a right moment to break industrial trends. As stated in The 2023 MHI Annual Industry Report, more than half of respondents have condemned their investments in innovations, including autonomous operations and green energy developments. More than 2000 companies have stated that they will invest in the following areas:

Cloud-Based Computing & Storage

Internet of Things (IoT)

Inventory Management & Network Optimization

Predictive Analytics

Robotics and Automated Systems

Self-guided vehicles (SGV) and automated guided vehicles (AGV)

Sensors and Automatic Identification

Wearable and Mobile Technologies

3D Printing

How to automate 70% of operations?

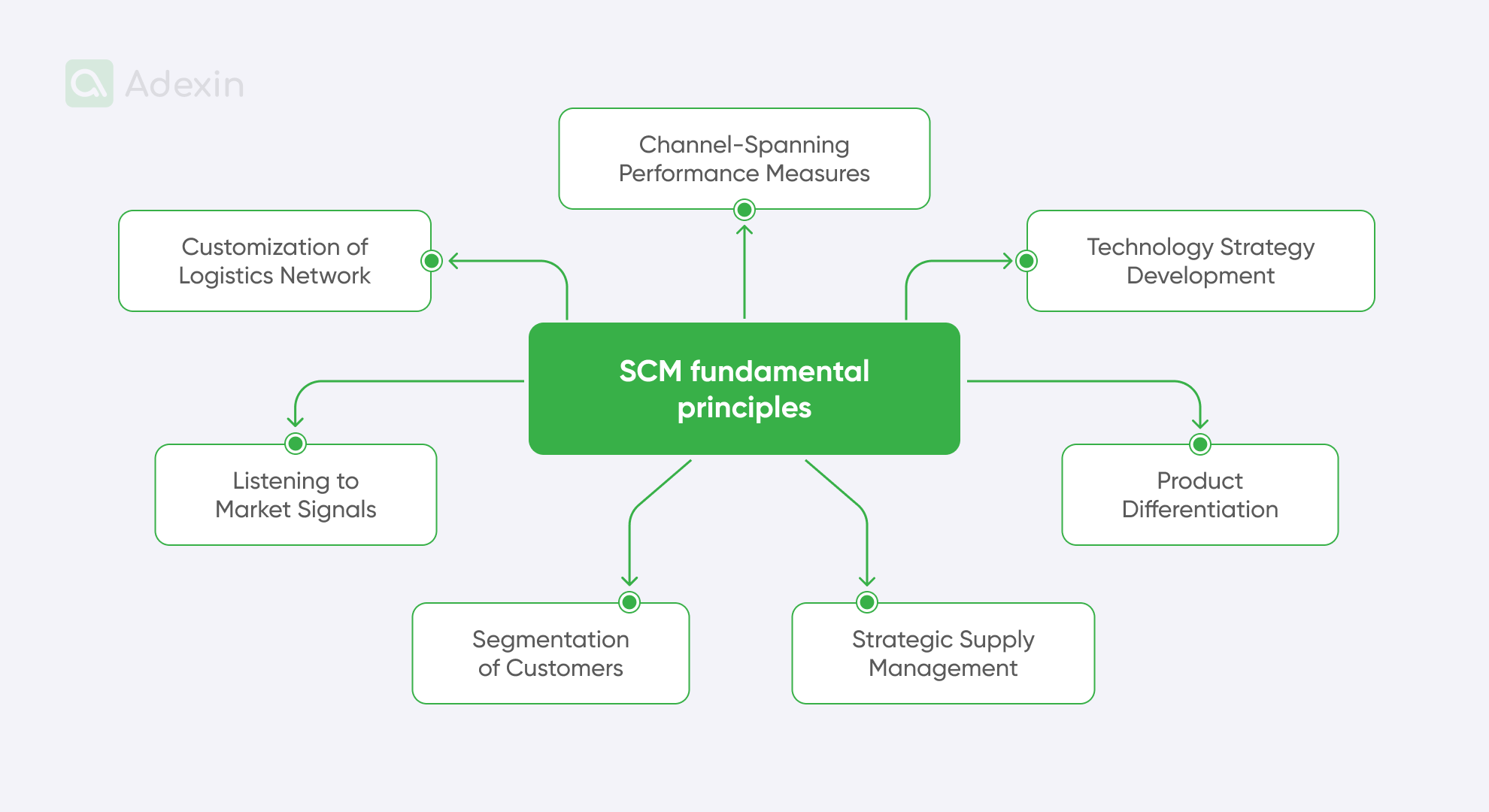

Supply Chain Management covers many operations, and sophisticated planning, which is essential for selecting the best possible carrier within the procurement process. You need to combine and optimize distribution and production sequences. Each principle for covering the entire subject was well defined by the Supply Chain Management Review. These principles have a visible influence on measurable results regarding autonomous operations.

Here are these principles:

Segmentation of customers based on the service needs and consequent adaptation.

Creating a responsive logistics network that seamlessly adapts to service requirements.

Vigilant interpretation of market signals and harmonious demand planning throughout the supply chain.

Personalizing products close to the customer to accelerate communication throughout the supply chain.

Strategic sourcing management to tactically reduce the total cost of ownership of materials.

Formulating an expansive supply chain-wide technology strategy to facilitate nuanced decision-making and provide a transparent overview of product, service, and information flows.

Adopt cross-channel performance metrics as a collective measure of success in effectively reaching the end user.

Each principle is linked to more autonomous operations that create less dependent businesses and are better tailored to business needs. But the sixth principle mentioned, which is about a supply chain-wide technology strategy, defines autonomy as a requirement, as it represents current technology development supporting all mentioned areas along with self-driving vehicles and solutions for the supply chain. Many examples illustrate the natural outcome of autonomous supply chains and applications of self-guided vehicles.

Need help with supply chain software development?

Learn how we can boost your business processes

Explore moreStudy case #1: Self-driving robots perform 70% of tasks in the "smart warehouse" from Alibaba

In 2018, Alibaba, one of the biggest retailers in the world, established the first smart warehouse with more than 700 robots responsible for moving goods to designated areas where employees can pick up items and ship them further. The deployment was focused on a warehouse floor with a facility covering about 3000m².

Study case #2: Autonomous vehicles will handle up to 85% of last-mile deliveries by 2025

In recent years, many companies, such as logistics providers like FedEx or UPS, have launched pilot programs and implemented new models for same-day delivery. UPS is starting deliveries by using Waymo's autonomous Class 8 trucks. According to McKinsey's forecast, autonomous vehicles will handle 85% of last-mile deliveries by 2025 (McKinsey, 2016).

Custom software development

Focusing on all these areas, custom software development is a significant requirement. Our company is a supporter of optimizing all business processes and introducing innovations thanks to our stack of technologies used. Often react, angular, javascript, typescript, and node js web development services are capable of delivering an advanced solution for any logistics niche.

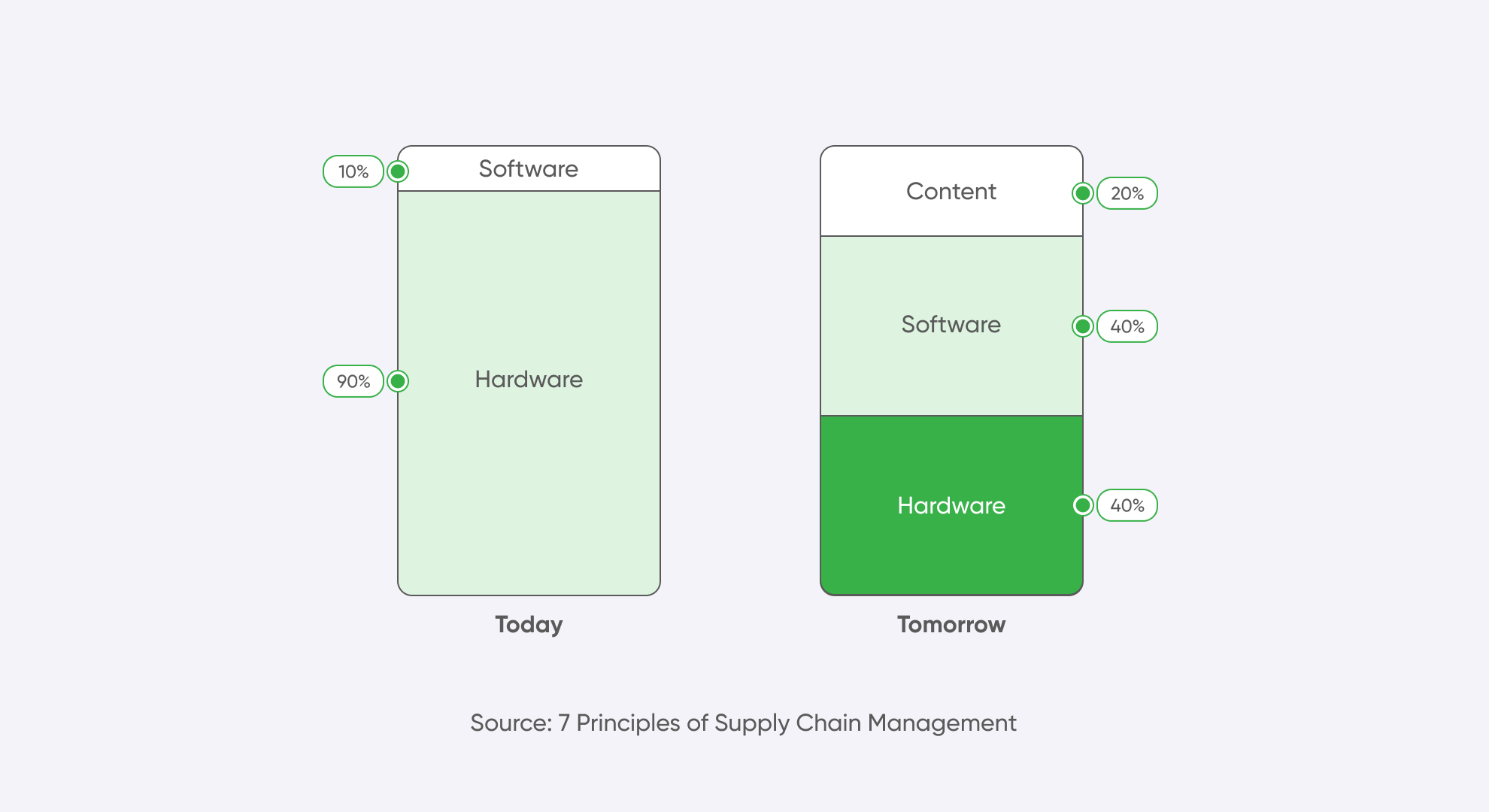

Let's take a look for one example, when we use SGV or AGV it is an electric vehicle that runs on pre-programmed software to operate in a controlled space, moving within fixed paths and known locations using guidance. It means these vehicles directly apply to the supply chain, supporting warehouse operations. There must be software in place to integrate all logistics legacy systems. The chart below shows the growing value of software compared to traditional vehicles.

Breaking industry trends: only 4 out of 10 businesses are using technology in the supply chain

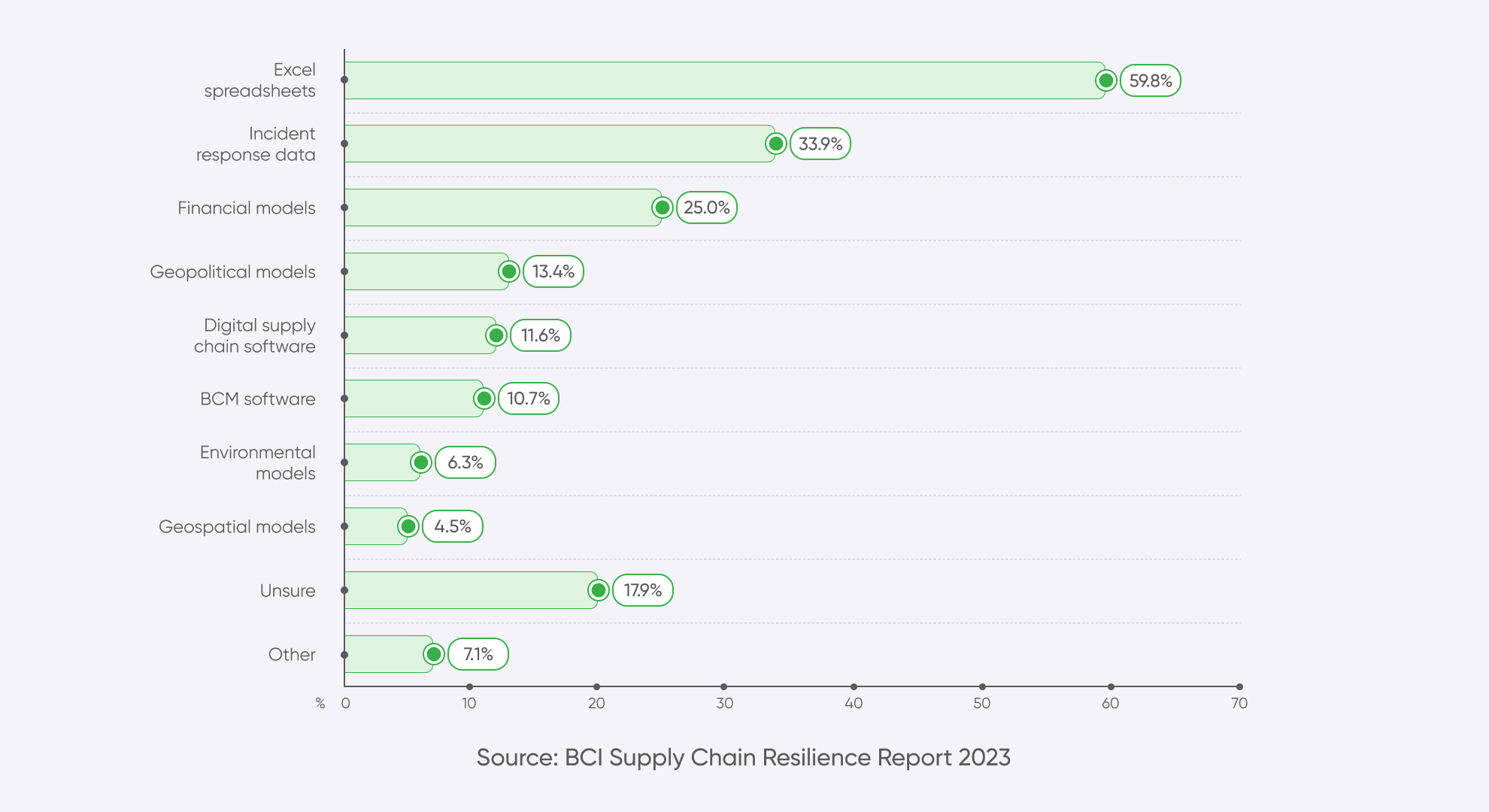

A very important aspect for each industry is data collection and automation. These areas are crucial for autonomous operations. Only by collecting data within supportive software do companies have a chance to be more accurate in their predictions.

Autonomous operations require fast data processing that cannot be performed by the typically used Excel spreadsheet. Data collection is one of the biggest problems in today's supply chains. Companies strive for data quality, for all costs, to implement more efficient solutions that can improve future operations and contribute to technology development toward autonomous operations.

Final takeaway

The autonomous supply chain is a closely emerging reality, but no company will likely become independent, in the supply chain context, in the next few years. Because of its nature, there is not much room in the supply chain for the complete elimination of technological shortcomings.

The autonomous supply chain highly depends on custom software development that finds ways to integrate various systems. It is how companies can shorten the path of digital transformation towards autonomous operations and eliminate technological shortcomings in the supply chain.

At Adexin, we're closely monitoring recent developments in transportation, logistics, and the supply chain. By understanding ongoing trends, we can help businesses be more agile in these uncertain times. Contact us today to learn more about custom software development for your industry.

Are you in search of a reliable tech partner?

Adexin can help with advanced logistics solutions

Contact us