If you're in the supply chain, this article is for you. We are discussing using the most popular app for the entire supply chain world. Excel has changed a lot, and no system to this day has been completely able to rip off its usage from the supply chain. Whether you already have a warehouse management system (WMS) or transport management system (TMS), these systems are still able to export data in CSV files, which is a format suitable for Excel and other systems to be opened or integrated. Excel still makes smaller operations and actions to cover daily routine tasks.

At Adexin, we cut our teeth working with Excel for supply chain and logistics. Our work experience has resulted in a brilliant understanding of the supply chain landscape and the actual usage of Excel as a multiverse tool for all-over operations. We share with you how Excel is used in the supply chain and how it integrates into logistics systems. You can gain a strong overview of what Excel is, its key elements, and where it is applicable as a powerful tool. You can learn also about Excel templates that can cover the unique needs of a company.

Excel in logistics systems

Today's logistics systems still link to MS Excel. As we said in the intro, you can still export data in CSV files from most systems, and logistics companies do this to open it in Excel format. So, whether you're using a complex system to run your supply chain and logistics, there is still an Excel spreadsheet in use somewhere.

In many cases, digital platforms took over the roles of logistics and supply chain operations. Many companies provide software that enables supply chain companies to excel with digital platforms. Frankly, digital platforms are part of Industry 4.0 and have been with us for a long time. Their capabilities provide many features, from procurement transparency to other services like personal management tasks.

We can conclude that Excel acts as a system of physical and technological records and reports that supply chain employees and managers use to collect, organize, present, and utilize logistics data collected at all system levels. So, its role is completely the same as, for example, a digital platform. However, you may need less skilled people to record, analyze, manage, and use supply chain data at every level based on a digital platform. Excel requires much more knowledge and skills to do it right, fast, and accurately.

You may not know that a digital platform, as a supply chain and logistics system, must enable effective business processes and workflows, which don't exist in typical MS Excel unless you build them manually on your own. You cannot perform forecasting, inventory management, distribution planning, reporting and ordering, order fulfillment, and so on by using Excel. Moreover, you cannot integrate IoT into Excel as easily as with a platform to monitor temperature, equipment maintenance, performance monitoring, etc.

You cannot do many things but you can still perform routine data management processes with Excel. On the other hand, you must know that using appropriate technology that is deployable and maintainable in a digital platform requires expertise and knowledge at every level of the supply chain. So, you'll most likely be able to build a simple solution for data management on your Excel rather than custom software on your own.

You may ask me, where are we going with this conclusion? So, I want to tell you that you can effectively use Excel in your supply chain and logistics without having custom logistics software, but the probability of failure might be much higher. This is because you need to maintain Excel on many levels more frequently than with, for example, a digital platform.

What are supply chain Excel templates?

When I worked in supply chain management, we used Excel for almost everything that needed to be registered and tracked. We created many supply chain Excel templates, which were pre-designed spreadsheets used to streamline various aspects of supply chain management. These templates offered our colleagues a structured framework so anyone, even less savvy employees, could save time and effort for tasks of all sizes.

The importance of setting up processes in various locations and providing people with robust tools (Excel templates) to work within the supply chain was very characteristic of that time.

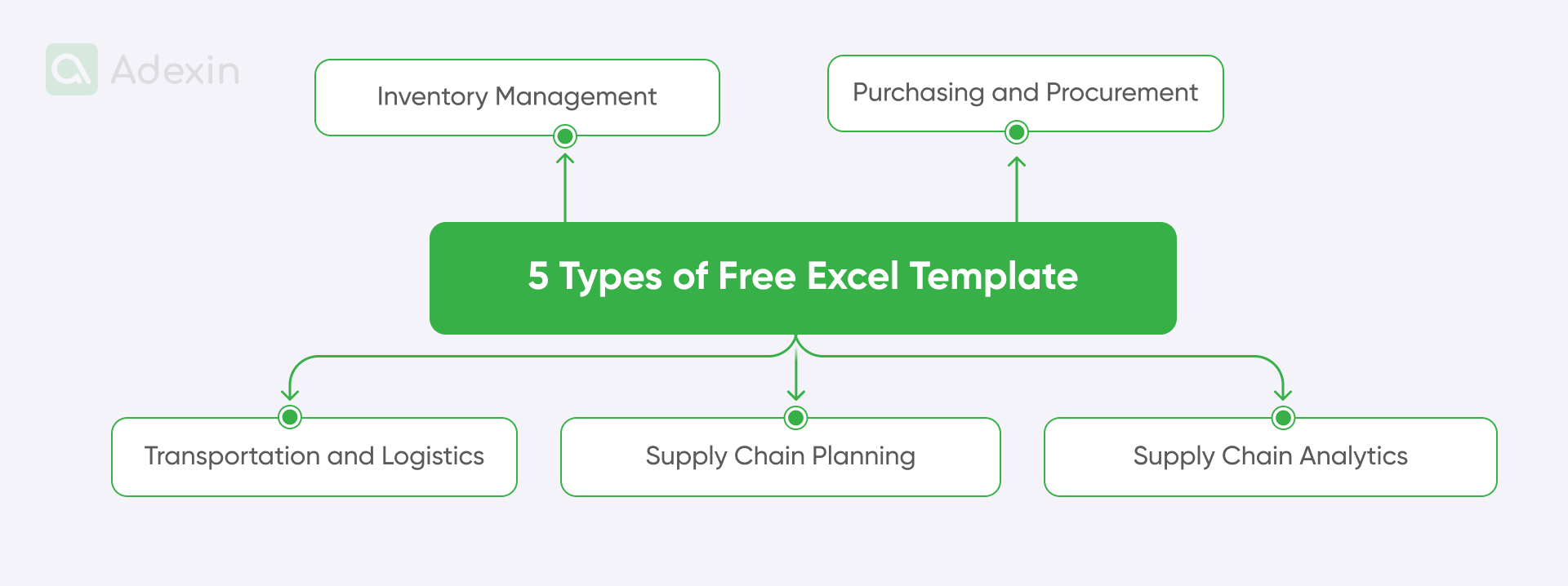

Well, I can give you several examples of how to use Excel for supply chain in your operations. Here are some of them, just, I would say, pretty frequent ones:

Inventory management

Stock tracking. You can create templates to monitor and track inventory levels. These can indicate reorder points and lead times to some point.

Demand forecasting. This Excel tool helps predict future product demand and optimize inventory planning.

ABC analysis. "ABC Excel" templates to categorize inventory based on value and usage to prioritize management.

Purchasing and procurement

Purchase order templates. You can build spreadsheets to standardize forms, which can help manage purchase orders efficiently.

Vendor performance tracking. These are the Excel templates to evaluate vendor performance and identify areas for improvement.

RFQ/RFP templates. These Excel templates are perfect for covering repetitive tasks such as creating requests for quotations or proposals.

Transportation and logistics

Route optimization. Templates to determine the most efficient routes for deliveries and minimize transportation costs.

Freight cost tracking. Excel transportation templates monitor freight expenses and identify cost-saving opportunities.

Carrier performance evaluation. The procurement team mostly created these Excel templates to assess the performance of transportation carriers.

Supply chain planning

Demand planning. This template was used to forecast demand and align supply with customer needs.

Capacity planning. Templates to ensure adequate production capacity to meet demand.

Supply chain risk assessment. Templates to identify potential risks and develop mitigation strategies.

Supply chain analytics

KPI tracking. Templates to monitor key performance indicators (KPIs) and measure supply chain performance.

Data analysis. Templates for analyzing supply chain data to identify trends and insights.

Using Excel in logistics and supply chain management

If I ask you, what would you choose? Could you speed over precision or do it the other way around? Working in supply chains, we talked with hundreds of companies, and we've seen that many organizations transitioning from spreadsheets to modern planning tools prioritize analysis speed. It is because these companies face the complexity of global supply chains, and planners seek tools that offer flexibility to adapt to rapidly changing conditions.

We've often said on our blog that companies should seek agility. It is how companies in fast-moving industries can set themselves apart. Instead of waiting hours for spreadsheet recalculations and fixing bugs in macros, we prove that modern planning applications deliver results in minutes at Adexin. We build various digital systems that enable deeper analysis of potential solutions. These tools are often designed to be as accessible as Excel, so users cannot capture the difference. However, the engine behind the architecture allows it to increase its calculation capability hundreds of times over.

Ease of adoption is a key differentiator. You cannot do this with Excel because it isn't as robust. I can give countless examples where new people came to work and old Excel tools (which means ready-to-use templates for various operations) crashed. No one could fix them. It crashed because someone made a change to a formula.

Thanks to custom software, companies can lower the adoption barrier. Organizations can expand the tool's use cases to include many tasks traditionally performed in spreadsheets. For example, unlike static analysis, modern planning tools continuously ingest and update data, providing a real-time view of each planning scenario.

The power of custom software over Excel

I don't want to say it because, at Adexin, we really love Excel, but honestly, Excel has a lot of challenges and there are so many better ways of handling data today. In fact, people are stuck in the old-fashioned way of managing data. In most logistics companies, there is no such pressure to avoid changing things that are already working. Transitioning to new tools means costs that people want to avoid. However, we already know that some changes are inevitable. It's just a matter of time.

So, it's clear that while multiple benefits come from using Excel, these can easily be outweighed by modern custom software for supply chain management. While Excel is a versatile tool, it can become limiting when dealing with complex, specialized tasks or large datasets.

Custom software offers several distinct advantages:

Tailored functionality. Designed to meet specific business needs, eliminating the need for workarounds or complex formulas.

Scalability. Easily adapts to growth and changing requirements, handling large datasets and complex calculations without performance issues.

Integration. Seamlessly connects with other systems, improving data flow and reducing errors.

Security. Enhanced protection for sensitive data, ensuring compliance with industry regulations.

Cost-effectiveness. Long-term efficiency and cost savings through reduced errors and improved operations.

Competitive advantage. Offers unique solutions and streamlined operations, providing a distinct edge in the market.

Here I would like to give one of the examples of Adexin development. Our team created and delivered an eProcurement solution for the German company Its Astra. We managed to completely remove Excel from the workflow, but at the same time left its functionality, and also added additional options to the web solution. The main value that the customer received, in this case, was the development of an advanced Excel-to-Web platform for eCommerce with built-in intelligence, capable of quickly and efficiently organizing the procurement process in an educational institution.

Need help with order management systems development?

We are happy to assist you

Explore moreFinale takeaway

Excel remains a valuable tool in supply chain management, particularly for smaller operations and routine tasks. Its ability to integrate with other systems and widespread familiarity makes it a convenient choice. However, custom software offers significant advantages for complex operations, large datasets, or advanced analytics.

Is your supply chain struggling with Excel's limitations? Let Adexin help you explore the potential of custom software. Our experts can assess your needs and develop tailored Excel-to-Web solutions to streamline your operations and drive growth.

Contact us today to schedule a consultation and learn how custom software can transform your supply chain.