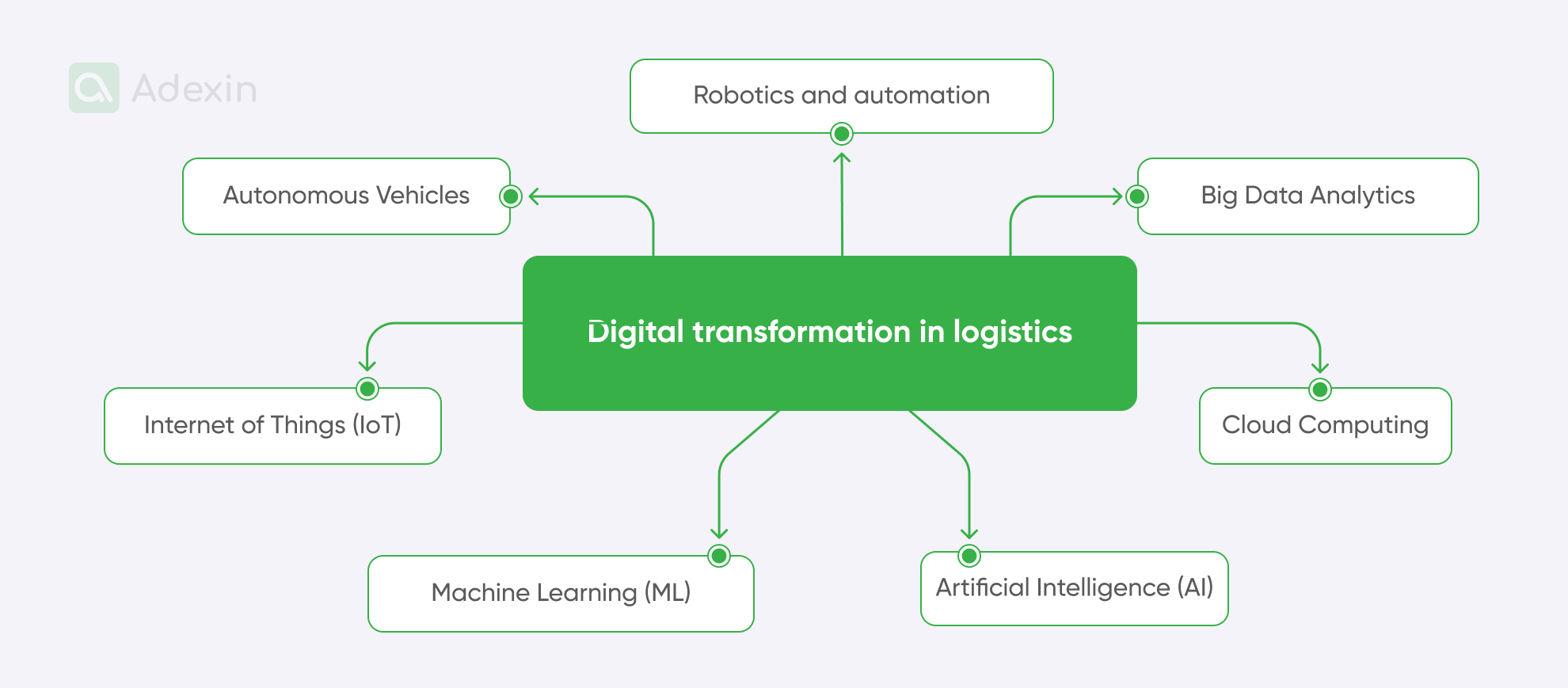

Digital transformation in logistics is bringing significant changes to the logistics industry as we know it. We can observe an increasing demand for minimizing human presence and removing manual work through automation, supported by modern custom software solutions and other technologies, such as the Internet of Things (IoT), Artificial Intelligence (AI), Big Data, predictive analytics, autonomous vehicles, robotics, and many others. This shift, based on digital transformation, is to help logistics companies lower operational costs in distribution and move away from the extensive use of internal resources needed to get the job done.

In 2026, digital transformation in logistics is no longer about adopting isolated technologies. It is about building AI-native logistics ecosystems. Companies are moving from simple automation toward predictive, self-optimizing supply chains powered by Generative AI, real-time analytics, digital twins, and intelligent orchestration platforms. Instead of reacting to disruptions, logistics leaders now predict, simulate, and automatically respond to risks before they impact operations.

In this article, we explain in closer detail what today's logistics look like and the factual value that logistics digital transformation is bringing to businesses. You'll get to know how to increase customer satisfaction with digital technologies. We offer our perspective on specific problems in logistics and highlight the potential downsides of incorporating unreliable approaches in this shifting process. Get to know more about digitization in logistics with expert insights from your industry's digital transformation journey.

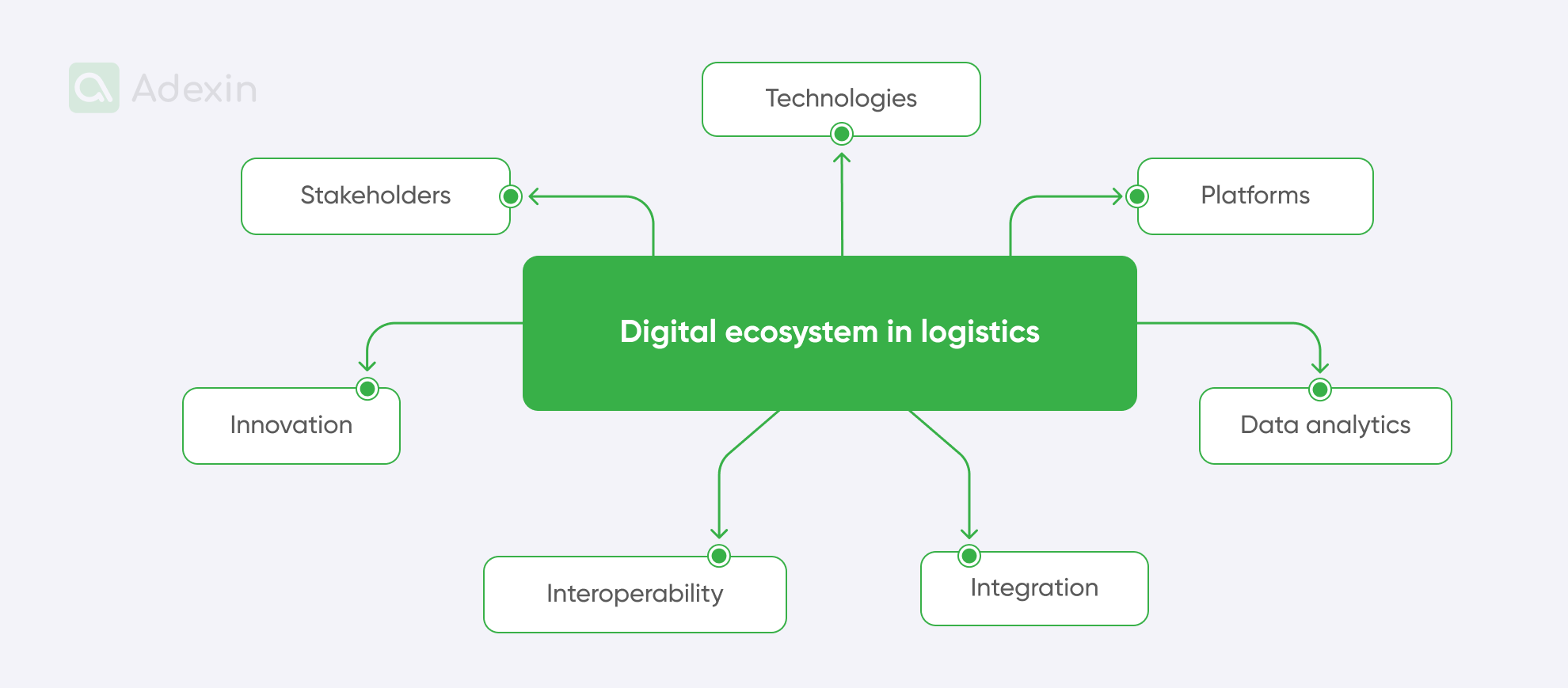

7 components of the digital ecosystem in logistics

When talking about digital transformation in logistics, it's important to understand the digital ecosystem of logistics. Along with overseeing the complexity of logistics's business operations, we'll become aware of which parts of logistics not only require digitization but also where we can really expect the major challenges and, what's also probable, where digitalization isn’t needed at all.

That’s right. Not all of the business units may require digital transformation. The entire process brings much more to the table, but the first step is to see the logistics constraints and understand the pain points of your personnel and processes. It's often said not to digitize processes in the logistics industry but to mobilize them and streamline the already established processes in logistics companies as much as possible with existing resources.

We will elaborate on this concept, one of those that may come from a deep analysis of each challenge of your business, but the main point is to outline the elements of digital ecosystems in logistics first. The digital ecosystem in the context of logistics involves a network of interconnected entities, technologies, and processes that together enable the efficient supply chain management and flow of goods and information throughout the supply chain. Here are the components of the digital ecosystem in logistics:

1. Stakeholders

This area encompasses the various stakeholders involved in the logistics process, such as manufacturers, suppliers, logistics service providers, carriers, wholesalers, retailers, and end consumers. Each participant plays a unique role in the supply chain and interacts with others to facilitate the flow of goods and information.

2. Technologies used by logistics companies

The digital ecosystem in logistics relies on a wide range of advanced technologies to support modern operations. These include cloud computing, artificial intelligence (AI), Generative AI, the Internet of Things (IoT), big data analytics, robotics, computer vision, digital twins, and blockchain. Together, these solutions enable real-time data processing, predictive analytics, intelligent automation, and autonomous decision-making, helping logistics companies increase visibility, resilience, and operational efficiency across the entire supply chain.

3. Platforms for logistics transformation

Industry-specific digital platforms are centralized hubs for managing logistics operations and facilitating stakeholder collaboration.

They are based on advanced custom software development. Some examples include fleet management systems (FMS), warehouse management systems (WMS), yard management systems (YMS), electronic data interchange (EDI) platforms for shipping, and e-commerce platforms, document management systems (DMS). These platforms provide tools to plan, track, optimize, and execute logistics processes and integrate various business units.

Need help with supply chain software development?

Learn how we can boost your business processes

Explore more4. Data analytics in the logistics industry

Data is the lifeblood of the digital ecosystem. The information collected provides insights that drive informed decision-making and further optimization. This includes data on inventory levels, shipping routes, demand forecasts, customer preferences, supplier performance, and operational metrics. Advanced analytical techniques extract actionable insights from this data, enabling continuous improvement and innovation.

In 2026, logistics analytics goes beyond descriptive dashboards. Predictive and prescriptive analytics powered by machine learning models enable companies to forecast disruptions, recommend optimal actions, and automatically trigger workflows. Real-time data streaming architectures allow companies to react within seconds rather than hours.

5. Integration in logistics companies

Logistics should be connected through seamless integration of systems and processes. This is critical to the smooth functioning of the digital ecosystem.

Integration enables the sharing of data and information across platforms and stakeholders, providing visibility and coordination across the supply chain. APIs (Application Programming Interfaces) and standardized data formats facilitate interoperability and enable efficient data exchange.

6. Interoperability in the transportation and logistics sector

Collaboration is the foundation of the digital ecosystem. The term Most commonly encompasses fostering collaboration among supply chain partners to achieve common goals. This includes sharing resources, information, and best practices and establishing strategic partnerships and alliances.

7. Innovation logistics sector

The digital ecosystem is characterized by constant innovation and adaptation to emerging technologies and market trends.

In a world where mobility is becoming increasingly universal, falling behind is not an option for any business.

Our years of experience have taught us that deploying custom software and mobile solutions can bring significant benefits in the years ahead. Changes in the logistics, supply chain, or transportation sectors typically do not happen quickly.

So, by providing a clear perspective on the long-term benefits of investing in custom software, you can clearly see that companies can ensure their continued success in the long term.

Digital logistics is a huge part of it, and companies within the ecosystem are investing in research and development to design new solutions and improve existing processes. This helps them stay ahead of the competition not only in logistics but the entire landscape of supply chains.

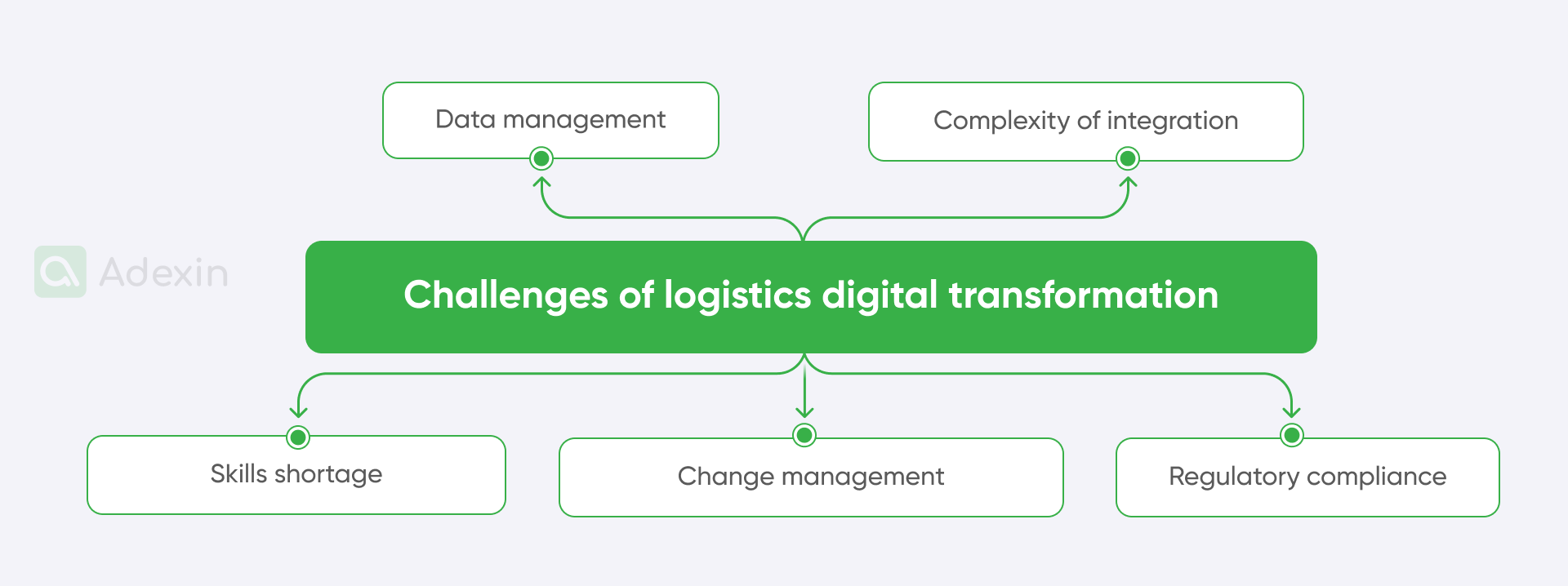

Challenges of logistics digital transformation

The digital transformation of logistics brings several challenges that companies must address to successfully adapt to the changing logistics landscape. These challenges include:

Complexity of integration in the logistics industry

Integrating different digital technologies, systems, and platforms across the supply chain can be complex and challenging. Achieving seamless interoperability between legacy systems and new technologies requires careful planning and investment and, more importantly, better collaboration among stakeholders. It may also require partnering with a custom software development partner in the long run.

Data management

Managing the large amounts of data generated by digital technologies such as IoT sensors, RFID tags, and GPS locators creates challenges related to data storage, security, quality, and privacy. This makes it a major challenge to ensure data accuracy and integrity across business units.

Companies also need to ensure regulatory compliance, which requires robust data management processes and technologies.

Over the years of experience, we have deployed many custom data management solutions, such as web cloud transformations, mobile and web applications, and data integration of different formats. Our digitalization consulting has enabled our clients to deploy affordable solutions through MVP development services that often progress to full-scale implementation.

But what exactly is data management in digital transformation, based on our experience? There are several important stages here that can bring the data of a company of any size into complete order, and which we have gone through more than once:

Modern data transformation in logistics relies on AI-based data validation, anomaly detection, and automated data enrichment rather than manual structuring processes.

In most cases, such transformations entail additional costs and resource requirements for companies. However, we use solutions that seem initially costly but subsequently bring processes to an advanced level.

Skills shortage and staffing shortage

The digital transformation in warehousing, supply chain, and logistics requires employees to have skills in new technologies such as data analytics, artificial intelligence, blockchain, and automation. IT experts are needed to implement these technologies in their operations.

However, there is often a need for more talent with these specialized skills. This leads to a skills gap in the industry, so you may need to find qualified experts and provide training to lower-level employees responsible for data management.

Change management

Implementing digital transformation initiatives involves significant organizational change. Employees must adapt to the changes, which include changes in processes, roles, and sometimes even culture.

Resistance to change from employees, stakeholders, and partners can hinder adoption and implementation. Effective change management strategies are essential to overcoming resistance and fostering a culture of innovation and collaboration.

Regulatory compliance

The logistics industry is subject to various regulatory requirements and compliance standards, which can vary by region and jurisdiction and, of course, by country.

Ensuring compliance with data privacy, security, environmental sustainability, and trade regulations can be challenging for companies operating in many markets. So, a significant challenge is complying with the many administrative changes and integrating them with physical assets.

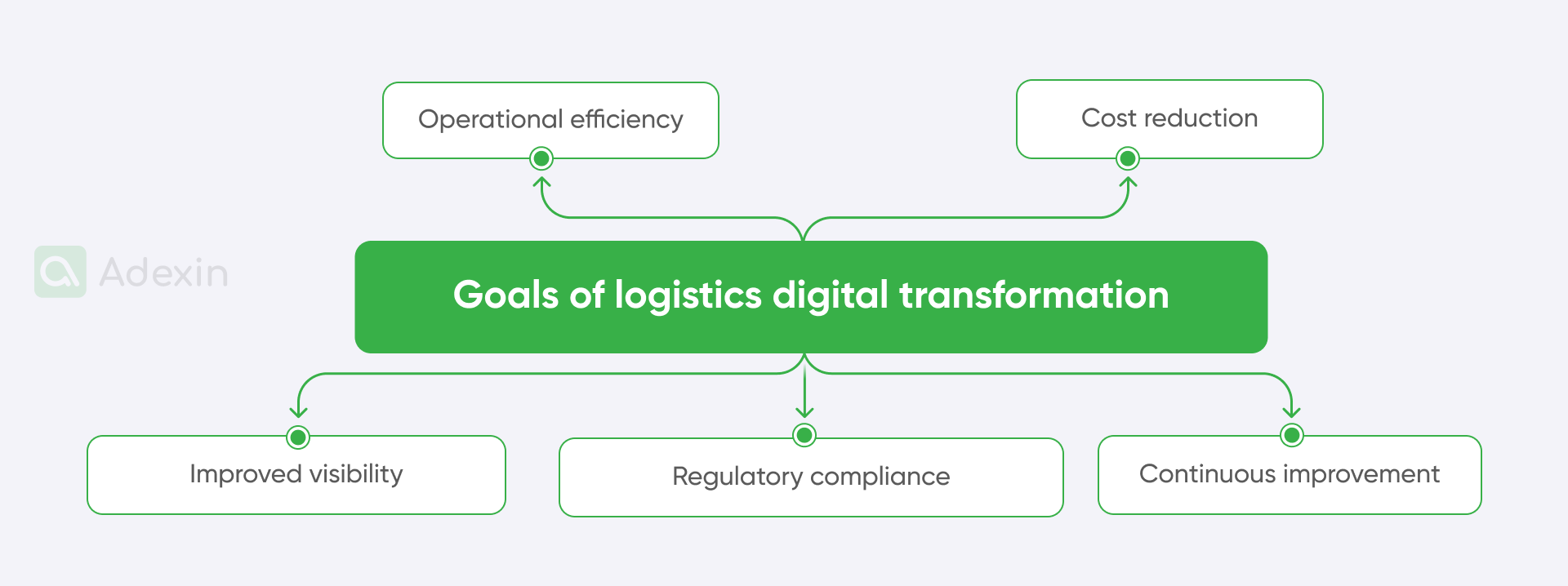

Top goals of logistics digital transformation

Digital logistics transformation has become essential for companies seeking to remain competitive and resilient in today's rapidly changing area of business operations. Here are some of the goals in logistics and supply chain management for logistics firms:

Operational efficiency: Through task automation, route optimization, and digital technology integration, logistics processes are streamlined, increasing operational efficiency.

Cost reduction: Through better planning, forecasting, and resource allocation, digital transformation identifies opportunities to reduce costs, such as reducing inefficiencies and minimizing transportation expenses.

Improved visibility in the logistics business: Integrating data from multiple sources enables end-to-end visibility across the supply chain and enhances customer satisfaction. It provides real-time insight into inventory levels, shipment status, and production schedules.

Regulatory compliance and risk management: Ensure compliance with regulatory requirements and mitigate security, privacy, and data protection risks.

Continuous improvement: Drive continuous improvement and innovation by collecting and analyzing data, measuring performance metrics, and implementing feedback loops.

The most important digital technologies in logistics

Many companies worldwide are already in the profound process of digitalizing their logistics operations. The process has advanced so that particular practices, such as using spreadsheets, which were once extensively adopted across all logistics sectors, are now being phased out. Companies aspire to benefit from increasingly sophisticated solutions to minimize manual work.

There is significant competitiveness among various countries worldwide regarding digital transformation in logistics. Every country in the world sees that by enabling businesses with digital solutions, they can gain a competitive edge and become more successful. This digital race become crucial to overcome joint pain points for shippers and logistics providers.

Here are the technologies that are used for digital transformation in logistics:

1. Blockchain

Blockchain technology digitizes tracking goods and transactions throughout the supply chain. This is a major advantage for logistics that secures and ensures transparency and integrity of data. This facilitates efficient and trustworthy information sharing among all stakeholders.

2. Robotics and automation

Digital robotics and automation systems use high-tech sensors and control systems to perform tasks traditionally performed by humans. By digitizing manual work processes, robots optimize productivity and ensure the accuracy and productivity of logistics operations.

Increasingly, robotics systems are enhanced with computer vision technologies. AI-powered cameras enable automated damage detection, pallet identification, barcode recognition, safety compliance monitoring, and real-time inventory counting without manual scanning. This significantly reduces human error while accelerating warehouse operations.

Of course, there are some downsides involving changes in the use of human labor, which could affect the labor market.

3. Big Data Analytics

Big Data digital analytics often relies on software platforms integrated with IoT devices to collect, process, and analyze massive amounts of data from various sources in the logistics infrastructure ecosystem. Using advanced algorithms, predictive analytics, and machine learning techniques is an approach that can uncover valuable insights to improve decision-making and help more accurately allocate resources and operational efficiencies. These capabilities can be further enhanced by deploying features in the mobile app for data collection, a practice we have successfully implemented with some customers.

4. Cloud Computing

Cloud computing provides on-demand access to a shared pool of computing resources and services over the Internet. In logistics, it enables the deployment of digital applications, storage of vast datasets, and seamless collaboration among supply chain partners, driving agility, scalability, and cost-efficiency.

Based on our extensive experience, cloud computing could be cost-efficient, especially when utilizing servers from Amazon. This scenario is particularly suitable for small and medium-sized businesses.

5. Internet of Things (IoT)

The digital Internet of Things connects physical objects, devices, and sensors to the Internet, enabling real-time data collection, monitoring, and control. In logistics, IoT devices digitize the tracking of assets, monitoring of environmental conditions, and optimization of fleet and inventory management processes.

When combined with AI, IoT enables real-time anomaly detection in temperature-sensitive shipments and predictive alerts in fleet management.

6. Artificial Intelligence (AI)

AI technologies digitize cognitive functions such as reasoning, learning, and problem-solving. In logistics, AI algorithms analyze digital data streams to optimize routes, predict demand, detect anomalies, and automate decision-making processes, enhancing operational efficiency and responsiveness.

The next wave of AI in logistics includes multi-agent systems capable of collaborating across departments from procurement to last-mile delivery. These AI ecosystems reduce manual coordination and enhance cross-functional alignment.

7. Machine Learning (ML)

Machine Learning algorithms digitize the process of learning from data patterns and trends to make predictions and decisions. In logistics, they quickly enable the digital automation of demand forecasting, inventory optimization, and predictive maintenance, improving resource utilization and cost-effectiveness. ML is supported by the various platforms that improve over efficiency by executing business operations.

8. Autonomous vehicles in logistics services

Digital autonomous vehicles utilize advanced sensors, GPS, and communication technologies to navigate and transport goods without human intervention. Digitizing transportation processes enables logistic service providers with safety, reliability, and efficiency in logistics operations, especially in last-mile delivery and freight transportation.

In such instances, we have observed automated vehicles as most suitable for short-distance deliveries in well-secured areas, where there is minimal risk of potential dangers from autonomous vehicles to pedestrians on the streets.

Are you in search of a reliable tech partner?

Adexin can help with advanced logistics solutions

Contact usFinal takeaway

The companies that win in 2026 will not simply digitize processes, they will build adaptive, intelligent logistics ecosystems. The shift from manual coordination to AI-orchestrated operations defines the next stage of supply chain evolution.

Digital transformation in supply chain, transportation, and logistics comes with many opportunities and benefits, primarily including using technology to reduce business costs. Software integration is a significant component of this digitization. Companies can lay the foundation for a more agile and flexible supply chain by adopting customized software solutions tailored to their unique needs. At the same time, in a single line, these software solutions enable the seamless integration of various digital tools and technologies. Which, in fact, allows companies to optimize processes and respond quickly to changing market dynamics.

At Adexin company, we understand the importance of staying ahead of the digital transformation in logistics. Our custom software development services are designed to help companies unlock the full potential of digital technologies. We enable companies to grow in an increasingly digital world.

Become more resilient and thriving in an era of digital transformation. Let us work with you to fuel your logistics operations toward greater efficiency, tackle the complexities of logistics digitization, and capitalize on the opportunities it creates for your business.