A custom lightweight WMS developed for a manufacturing company in the MENA region to support multi-warehouse inventory control, component traceability, and scalable logistics operations.

Consulting

We can consult on constructing a practical and beneficial technical solution for your product.

Custom software

We deliver highly specialized, cutting-edge solutions for all niches of the logistics industry.

Dedicated teams

Jumpstart your long-term projects with a team of hand-picked professionals powered by AI.

Services

Technologies

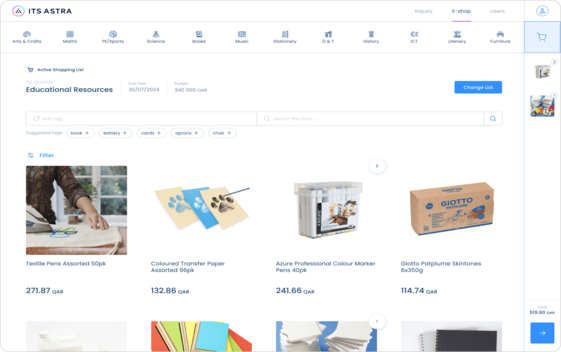

Lightweight WMS for manufacturing operations

- RegionMENA

- Duration2024

- Services

- IndustryLogisticsIntralogistics

Scaling multi-warehouse operations with a future-ready WMS

Developed with growth in mind, this implementation delivers digital clarity and operational control with over five core modules covering everything from material tracking to internal workflows. With unlimited users, fully digital inventory records, and a built-in barcode-ready architecture, this system is built to adapt and grow.

The solution serves as a centralized warehouse management platform for manufacturing-driven supply chains with complex internal logistics.

Here’s what the numbers say about the deployment:

- 4 main warehouses in the MENA region are already operational

- 5+ core operational modules providing logistics and inventory control

- Unlimited users supported through multi-role access

- 100% digital record keeping with barcoding and features

- 3-month accelerated development with Adexin Tools Framework

What were the operational and technical challenges?

The core challenge was building a system from scratch, as no digital inventory or warehouse tools existed. The initial setup was focused on multiple locations with scalability and visibility across the organization in mind.

Hardware integration, like barcode printers and scanners, was undefined, delaying automation. Without mobile apps, all stock tracking and transfers between warehouses were manual. Additionally, the system had to manage complex logistics, including components movement, quarantines, and production workflows, all within a scalable and flexible framework.

Client overview

The client is a manufacturing company (under NDA). With its main operations and warehouses in the MENA region, the company supports its manufacturing operations with fast, reliable logistics and rapid response to all customer requests.

Their operations are based on production, storing, and shipping orders within tight lead times. Effective inventory control is critical to the mission, making the move to a digital warehouse solution a key step in improving traceability, speed, and scalability of operations.

The company’s warehouse operations play a critical role in ensuring production continuity and meeting tight delivery timelines.

Let’s find the right solution together

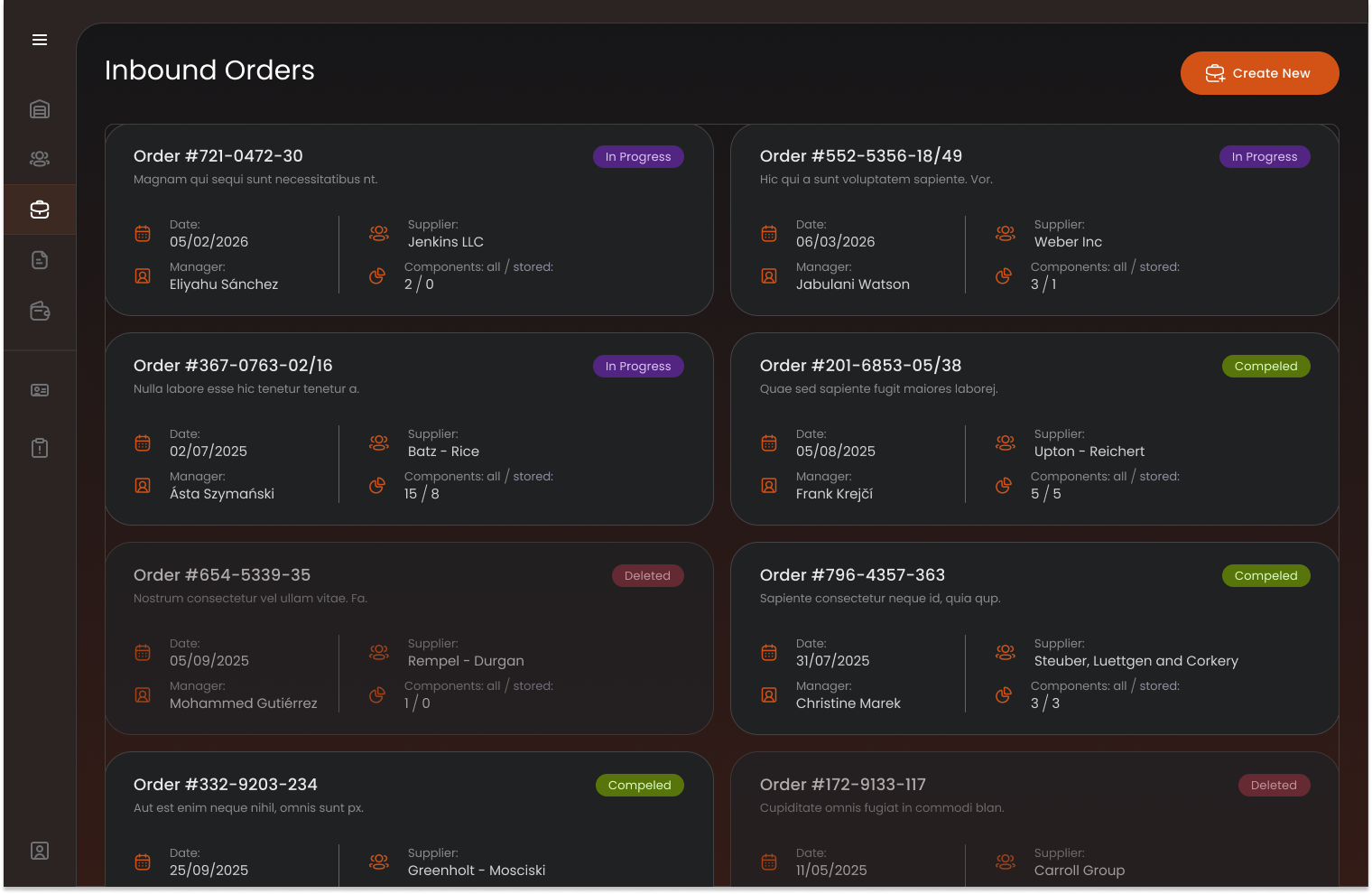

We delivered a lightweight WMS for scalable manufacturing logistics

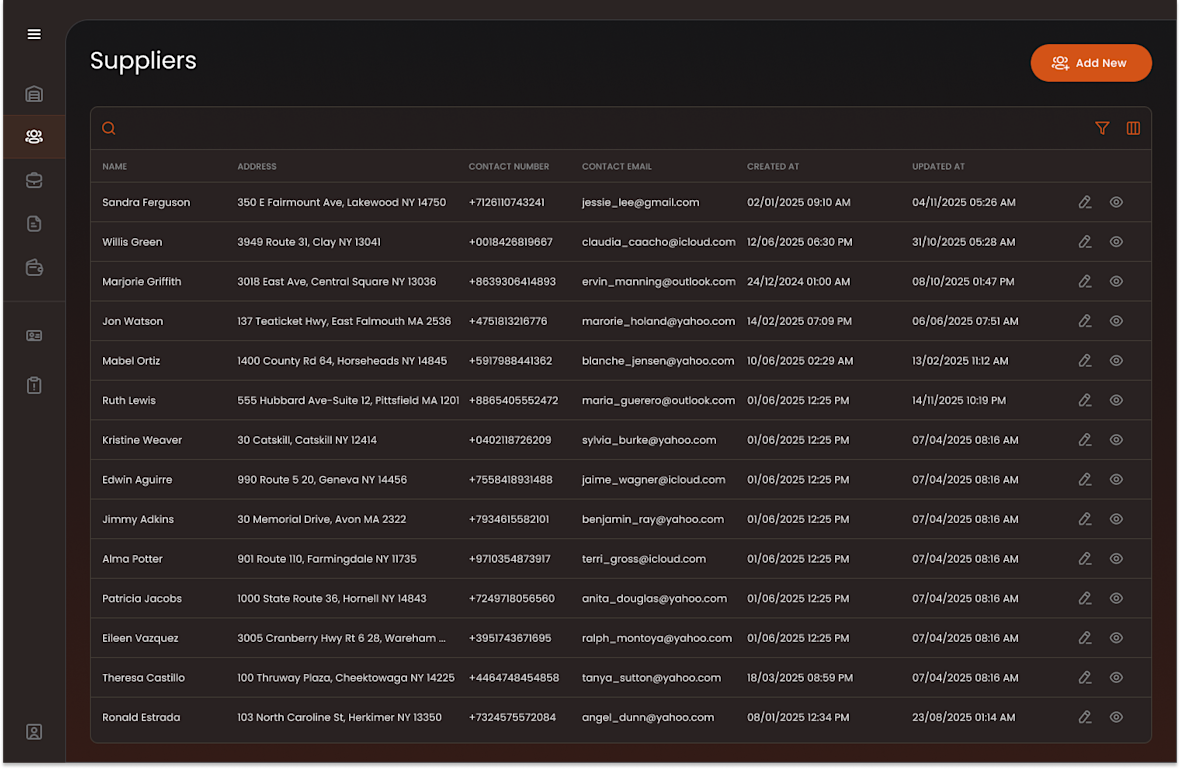

- A warehouse-centric inventory platform. Custom-built to support multiple warehouses and transfer components between them with a structure adaptable to future expansion.

- Components and location visibility. Offers real-time tracking and categorization of stock across zones and storage types.

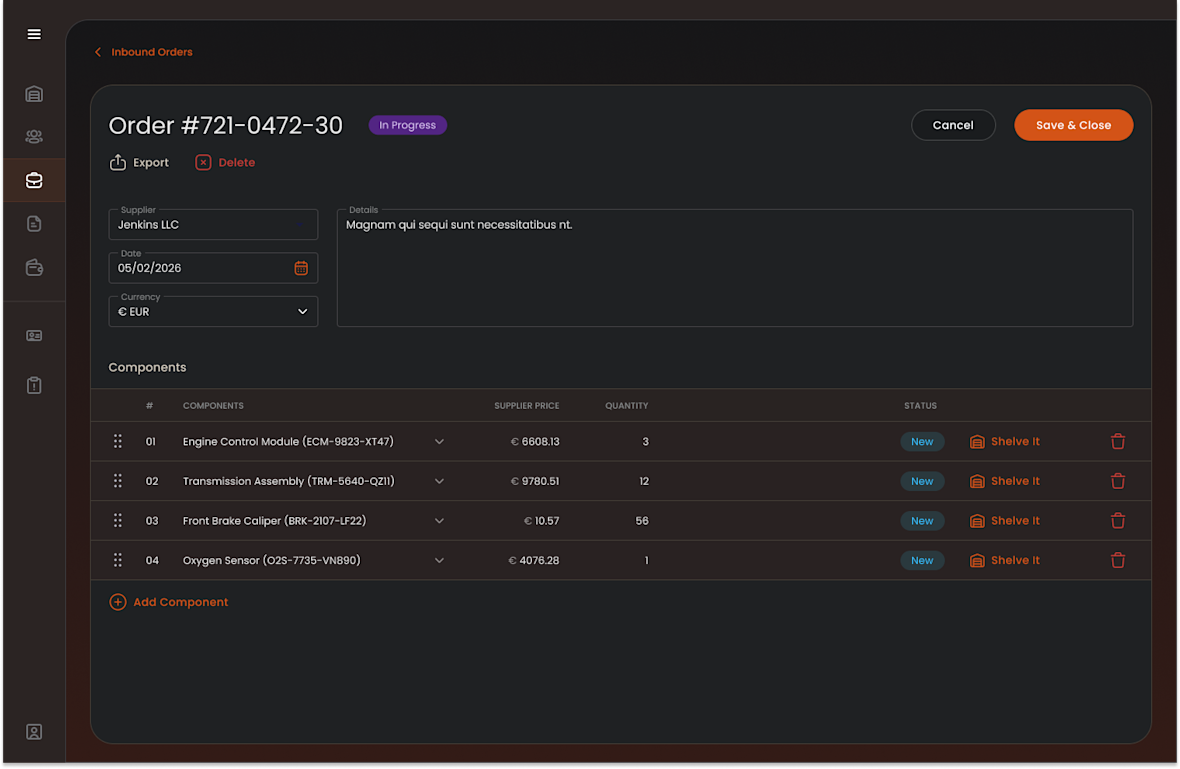

- Inbound and outbound logistics. Enables complete tracking of goods from supplier delivery to client dispatch, with full historical logs.

- Internal transfers to production. Supports seamless stock relocation between warehouses and zones while maintaining audit-ready movement history.

- Barcode-ready labeling. Generates print-ready labels in anticipation of full barcode integration for improved physical tracking.

- Flexible user management. Role-based access controls are created for operational efficiency and scalability.

Our team delivered and implemented a custom warehouse and inventory management platform tailored to the client's warehouse-centric operations. The system provides real-time visibility, streamlined logistics, and flexible user control, laying the foundation for scalable growth and efficient stock handling. The solution simplifies inventory oversight, facilitates logistics coordination, and ensures data accuracy across all movements between warehouses.

Project results

The digital transformation of warehouse operations marked a major milestone in the client’s manufacturing and logistics modernization journey. Key results of the project include:

- Replacement of manual processes with streamlined digital workflows

- Significant improvement in traceability across locations

- Increased team confidence in managing day-to-day logistics

- Enhanced staff effectiveness through a lightweight mobile application

- Full data accuracy and traceability maintained throughout operations

How it works

Technology stack

The combination of technologies we used to complete this task.

Not sure if Adexin is suitable for the task? Schedule a free consultation.

Other Case Studies

Here are more case studies to help determine if Adexin is the right fit for your business/project.