The optimization process in logistics and transportation is helping us deal with various challenges along the supply chain planning journey. If warehousing is tightly connected to manufacturing planning, the delivery of goods from the warehouse to the shop floor should be well-optimized to save costs and decrease inventory volumes. In the case of manufacturing companies collaborating with various suppliers, there is a high demand to keep deliveries on time and just-in-time.

Nevertheless, coordinating such a process requires a connection between suppliers and smooth data exchange. This can be facilitated by custom software that provides your business with comprehensive features for handling shipments in the Just-in-Time model. In this article, you can learn more about how your transportation can be improved across the supply chain with custom software for just-in-time shipping.

What is just-in-time shipping?

Many business processes and systems are dedicated to transport optimization to improve delivery to end customers. However, along the journey to the customer, many stages in transportation and logistics may require optimization and are tightly connected to supply chain planning. With the topic of optimization in mind, we can refer to a much broader perspective that includes more transportation improvements from many different angles.

One process that helps companies continuously optimize transport is just-in-time (JIT) delivery. JIT involves connecting with your suppliers, regardless of their location, and enabling your business with perfect forecasting for on-time delivery. This process can help you keep your business up and running by preventing shortages of goods in distribution or production.

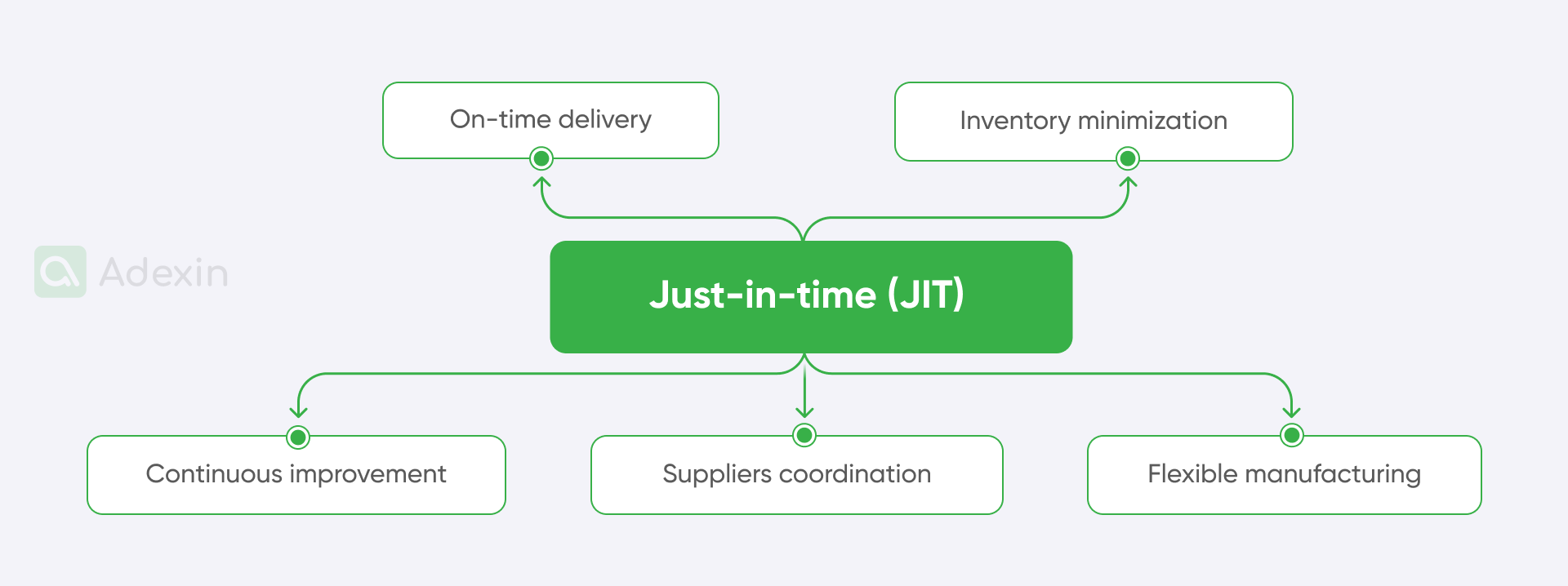

Just-in-time (JIT) includes the following principles:

On-time delivery. JIT emphasizes delivering products or materials exactly when they are needed in the production process.

Inventory minimization. JIT seeks to minimize inventory levels by ensuring that goods are received or produced exactly on time.

Continuous improvement. JIT encourages a culture of continuous improvement in all aspects of the manufacturing process.

Suppliers coordination. Coordination of the suppliers and partnering with them is critical in JIT. You can build strong relationships with suppliers to help ensure reliable and timely delivery.

Flexible manufacturing. JIT promotes flexibility in production processes to quickly adapt to changes in customer requirements.

Quality control. Quality is a fundamental aspect of JIT by ensuring that each component or product meets high-quality standards.

It's worth noticing that transport optimization is an ongoing trend in the supply chain anticipated by many CEOs. Regardless of the size of your business, whether small or medium-sized, as many logistics and transportation CEOs now recognize, you may also consider new approaches to building a case for supply chain digitalization. One way is to implement processes for transport optimization. One of those is JIT, which is one of the most effective, especially when utilizing custom software development.

What are just-in-time delivery examples?

Just-in-time (JIT) shipping is about delivering goods to production from the warehouse at the time when they are needed. We can imagine a large facility that is busy producing furniture, such as IKEA. A company like this will have several warehouses and production lines in different locations. They may be required to integrate the entire shipping process across various channels to receive different components on time in their manufacturing facility. For this purpose, they will need software that can coordinate shipping times and deliveries (ETA) from each warehouse to the shop floor facility.

Another example is a small manufacturing company that depends on delivering raw materials to its facility from external suppliers. For this purpose, the company needs to keep an eye on each delivery stage, from loading to collection time, to ensure that competent raw materials will be delivered on time. By using custom software that integrates shipping operations from various suppliers, a small manufacturing business will be able to prevent production delays.

These two examples provide a clear perspective on how Just-in-Time should work. It can be good for small and medium-sized businesses as well as for larger companies. To implement such a process in transportation and logistics, the company will require custom software to integrate different business parts. Such a system will provide the company with extensive capabilities for optimization and forecasting, for example, blockchain-backed custom DMS, which simplified the client’s operations significantly and saved a lot of time on processing and approval of documents, thereby reducing delivery. Along the way, you can get a lot of benefits that can definitely increase your efficiency.

Need help with document management systems development?

Learn how we can boost your business processes

Explore moreBenefits JIT delivery

There is no doubt that JIT belongs to one of the ways of transport optimization alongside improvements for deliverability along the entire supply chain. Here, we highlight some of the most important benefits of JIT delivery:

Improved production control. You can effectively manage production by controlling output and quickly adjusting to spikes in demand with just-in-time (JIT) deliveries.

Avoiding waste. JIT inventory management protects your company from unwanted products, damaged parts, and wasted materials by ordering materials as needed.

Lower warehousing costs. JIT delivery saves on warehousing costs because products are produced and shipped only when they are needed.

Lower shipping costs. With lower shipping frequency, you can reduce transportation costs.

Just-in-time in logistics: Implementation

To start with the implementation of JIT, you need to be sure that you have the right partner that understands the complexities of the supply chain. Here are the elements that are important for JIT implementation in your transportation and logistics operations:

Conduct in-depth process analyses.

Establish trust with contractors, especially for future sharing of up-to-date order information for quick readiness.

Adopt appropriate information technology, including EDI and SCM systems, based on custom software development.

Please include in your process attention to suppliers' shifts beyond pricing (it might be controlled stakeholders' business operability based on carrier audits).

Select storage systems and warehouse layouts to minimize routes for equipment operators.

Use tools and software features for conveyor loops, mini-load warehouses, overhead shelving, and racking, providing flexibility in handling goods based on rotation and shipments.

Strategic planning of a warehouse's loading docks is critical for efficient receiving and shipping.

Investing in analytical tools supported by custom software for predicting demand.

What are the problems with JIT implementation?

Companies that want to implement JIT should be ready for digitization. The lack of experience with software solutions for this purpose is the biggest challenge. If your business needs software for transport optimization, that may also cause problems arising from uncertainty. The last challenge is the most common one among small and medium-sized businesses.

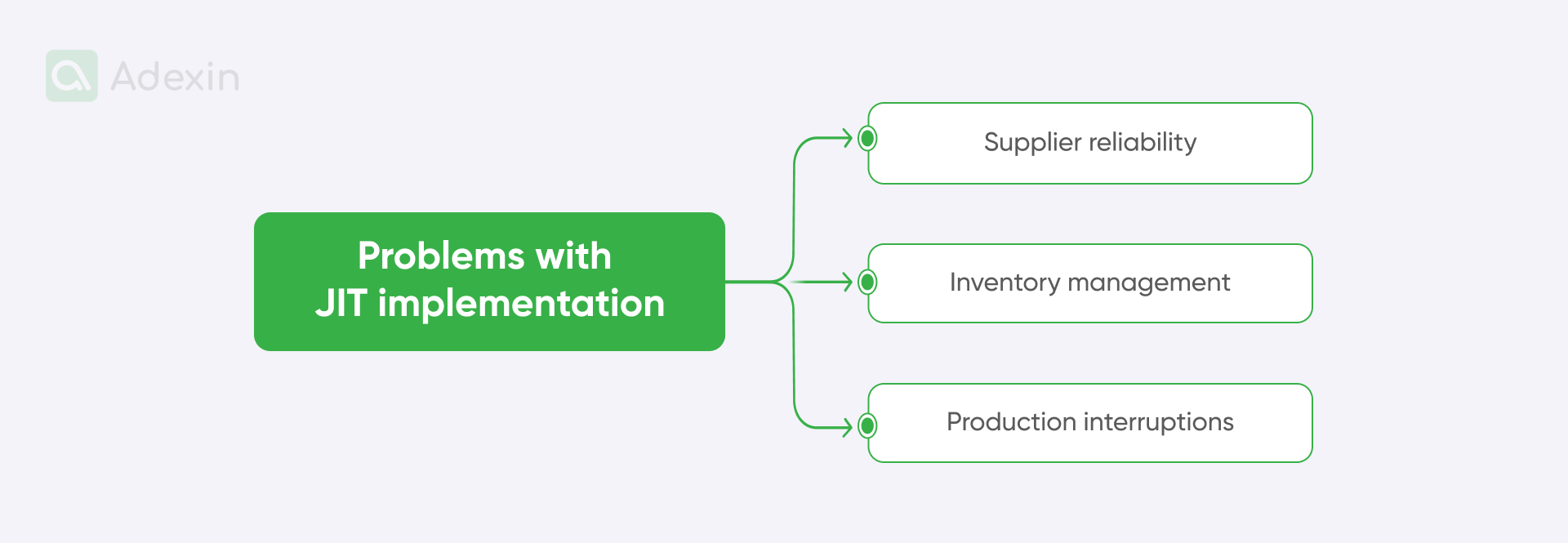

Here are the three main problems with JIT implementation:

Supplier reliability

Dependence on the timeliness and consistency of suppliers can be a risk. If suppliers fail to deliver components or materials on time, it can disrupt the entire production process.

Inventory management

Keeping inventory levels low leaves little room for error. Any unexpected increase in demand or disruption in the supply chain can lead to shortages, affecting production schedules.

Production interruptions

JIT is based on a smooth and continuous flow of production. Any disruption caused by machine breakdowns or unforeseen events can halt production and affect delivery schedules.

To cope with this problem in the best possible way, engage in cooperation with a software company that understands the complexity of transportation businesses. Because many aspects of transportation optimization come into play, it might be challenging for startups. However, the most important aspect is that cooperation with a custom software development company can bring long-term benefits to the business in a relatively short time.

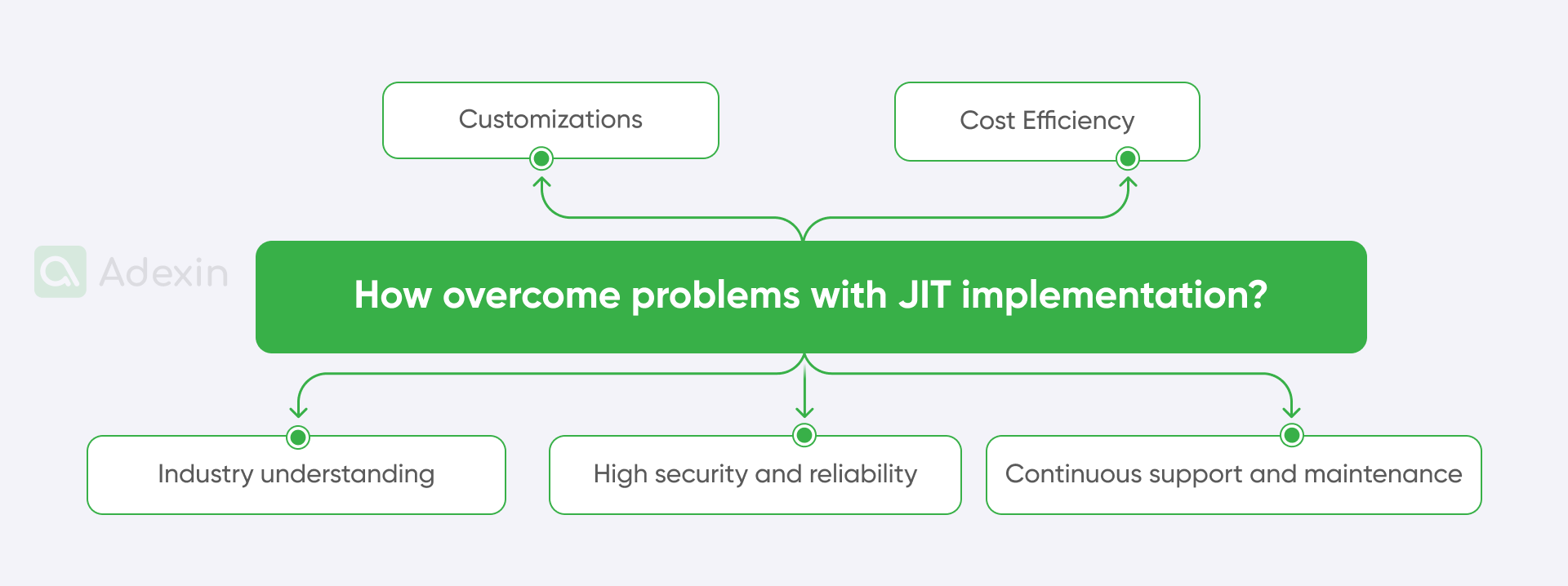

Here are the benefits related to cooperation with a custom software development business for transportation, logistics, and supply chain, that can help you also overcome problems with JIT implementation:

Customizations

Solutions tailored to specific business needs also allow for much faster transport or logistics operations scaling.

Cost Efficiency

Optimized processes lead to increased efficiency and long-term savings for your organization.

Industry understanding

Expertise in industry challenges that provide targeted transportation, logistics, and supply chain solutions.

High security and reliability

Strong security measures that protect sensitive data and ensure reliability within the organization.

Continuous support and maintenance

Ongoing support and timely updates minimize downtime and resolve issues quickly with dedicated teams.

How do you optimize just-in-time shipping and delivery?

By using JIT for shipping and delivery, you'll be able to optimize your transportation and logistics business processes within the supply chain. If your business has already implemented JIT, you may be able to reveal other benefits of that system. You can actually keep on going with continuous improvement for your just-in-time shipping and delivery. One of the ways is to use built-in functions from your custom software, such as the Transport Management System (TMS), that can implement JIT in your business.

Here are elements that help you optimize your JIT by using custom software solutions:

Data Optimization. You can use emerging data sources to comprehensively understand transportation. Moreover, you can evaluate data sets based on sample size, multiple sources, and regular updates.

Transparency of algorithms. Custom software can enable you to better understand transportation data algorithms for transparent data handling. You can utilize machine learning and deploy data science knowledge to drive higher revenues.

Visualization and sensors. Using advanced data processing algorithms for practical indicators connected by the IoT solutions. You can use sensors and tachometers to perform improvement data processing.

Are you in search of a reliable tech partner?

Adexin can help with advanced logistics solutions

Contact usFinal takeaway

Transport optimization includes many systems and processes that can elevate your business above leading transportation and logistics companies globally or within local supply chains. With just-in-time delivery, your business can become more effective and competitive, but this is just one aspect that customers truly appreciate when choosing a business partner.

There are multiple benefits to explore, and to ensure your business remains competitive, consider implementing transportation custom software. This software will provide flexible solutions to cope with the challenges of today's logistics and transportation.

Adexin is a custom node js development agency that develops solutions to help you implement transportation optimization practices, such as just-in-time delivery. You can benefit from our knowledge about logistics and transportation to get the best-suited solution for your business needs. Let's schedule an introduction call to provide you with more information about it. Contact us today.