This article will explore the world of logistics and supply chain management (SCM) more deeply. We use direct experience from our work in the field of software development for logistics and SCM, as well as knowledge from business process management and how it adapts to software solutions. We serve useful insights for global logistics managers and also small business operators that need to meet customer's requirements in today's global economy. This article can also give supply chain analysts or procurement managers many interesting tips, especially if your business is beginning to transform and expand operations.

We were able to outline these two key players in delivering products to the home and in B2B structures. We can see that they have some things in common, but they still operate at different levels within the overall system. Here, you can learn about logistics and SCM. We are also telling you about the main architect of the product journey. It is a strategic approach that oversees everything involved in bringing a product to life, from sourcing raw materials to production, distribution, and warehousing.

We're going live with an explanation of logistics management, an efficient operator responsible for the daily execution of the movement of goods within a specific segment of the supply chain. Learn about transportation (road, air, sea), warehousing (storage, picking, packing, shipping), inventory management, and finally, order fulfillment.

What is logistics and supply chain management?

Supply chain and logistics operations have common sense, which is defined by its operations. In short, here are the definitions of both:

Supply chain management (SCM) is the strategic planning and management of the entire flow of a product or service, including how the goods are handled from raw materials to the end customer.

Logistics management focuses on detailed planning and execution of the physical movement and storage of goods, which is based on a supply chain.

You need to move further throughout this article to see the difference more clearly. But you can think of it that way: building a very complex organization or developing a program. SCM, which means supply chain management, can be the architect, where you design the blueprints and source materials and coordinate different experts to support that project, while logistics is the contractor. This contractor must ensure the materials arrive on time and are stored properly. It focuses on using it efficiently to finalize that project and shape the organization's structures according to the plan.

Understanding the distinct and complementary roles of SCM and logistics can help companies ensure a well-profiled business system. Along with this, deep know-how about the industry is required to provide SCM and logistics services. With this approach, you can finalize and move with an efficient and cost-effective flow of goods. It's all about ultimately satisfying customers.

Logistics vs supply chain: main differences

For the managers and supervisors, it will be no challenge to differentiate between the terms "logistics" and "supply chain." Both are often used simultaneously in the business because the operation modalities overlap. You cannot say that logistics will fall apart from the supply chain because the supply chain cannot exist without logistics. However, there's a crucial distinction between them. Here's a breakdown to clarify the difference:

What about logistics? Let's start with its focus

The focus of logistics is devoted to the physical movement, storage, and coordination of goods within a specific segment of the supply chain. So, this is the first link where you can find something in common. This operation involves warehouse management, transportation (road, air, sea, intermodal transportation), and order fulfillment. The last one is very characteristic of contract logistics.

Here, we can outline the scope of logistics management. Logistics is a more narrow concept. Its scope is the practical execution of getting goods from one point to another within a specific timeframe and budget. However, it will most likely be narrowed to this, including intralogistics and warehouse operations.

See what example we have on logistics management

First of all, I have worked in a supply chain business that offered logistics services within contract logistics. We managed a warehouse based on a distribution center, efficiently receiving goods, picking and proper packaging orders, and shipping them to customers. This is the realm of logistics, so you can see where it was narrowed down.

Taking this example from the European company that produces bicycles, we can focus more on the operations related to what is happening under the warehouse's roof. So, a manufacturing warehouse in China accepted parts to assemble a bicycle that was shipped to Europe, where they were stored and shipped to the end customers from the distribution center.

See what is its focus of effective supply chain management

The supply chain is the entire network of activities that bring a product from its raw materials, integrating with production planning and shipping to the end customer. It is a very long way for all stakeholders in the business, and it works the way around. So then, the supply chain can be involved in reverse logistics, which means that we also have return processes here. It encompasses everything from sourcing, manufacturing, and warehousing to transportation, distribution, and customer service. It's a bit of everything, but I am not sure it means that it is the same as logistics.

What is the scope of the Supply chain? The scope of supply chain management is a broader concept than logistics handled by supply chain managers. We need to see it as different management approaches and administration. So, to better operate in supply chain management, we need to understand it holistically with all supply chain partners, by using supply chain data.

Supply chain management encompasses all the interconnected processes and stakeholders that contribute to delivering a product. This is something that is laying down the responsibility of supply chain management professionals.

Let us see now one example of a supply chain

Let's take, for example, delivering goods from China's manufacturing facility to Europe Rotterdam and then to the end customers. So, the supply chain solution here will be maintaining transport modes from China to Europe and then to the distribution center (or assembly center) and customers. Consider a company that manufactures bicycles.

Their supply chain would involve sourcing raw materials like steel and rubber, manufacturing the bikes, storing them in warehouses, and transporting them to retailers. The shipment from China will most likely be via the Suez Canal with a container ship.

Then, a container with goods will be unloaded in Rotterdam and transported on truck trailers to the distribution center in the Netherlands. Thus, the supply chain will take care of transportation from China ahead of the Netherlands and further plan how it will be delivered to the end customers (mostly the trailers, etc.)

Need help with custom software development for your supply chain business?

Learn how we can help you

Explore moreWhat is an analogy between logistics and supply chain?

Let's shrink these two terms. Logistics is an execution within the supply chain, and the supply chain is a bigger picture, which encompasses all the steps that lead to delivering a product. We must consider the supply chain a complex process where each ingredient represents a different step (sourcing, manufacturing).

Logistics would be the act of following some part of that process. Logistics must ensure the ingredients are collected (warehousing), prepared (order picking), and delivered (transportation) to create the final customer. Looking at the example from the supply chain, logistics would be a crucial part of this supply chain, ensuring the smooth movement of bikes at various stages.

Logistics vs supply chain: main challenges

While both logistics and supply chain management deal with getting goods from point A to point B. They face distinct challenges due to their different scopes. It's more about what is explained above, but going deeper into the details, you'll be able to see what both areas are struggling with to remain, let's say, top businesses in the industry. We have broken down it into two groups of challenges, giving you, at the end of this section, major differences to see.

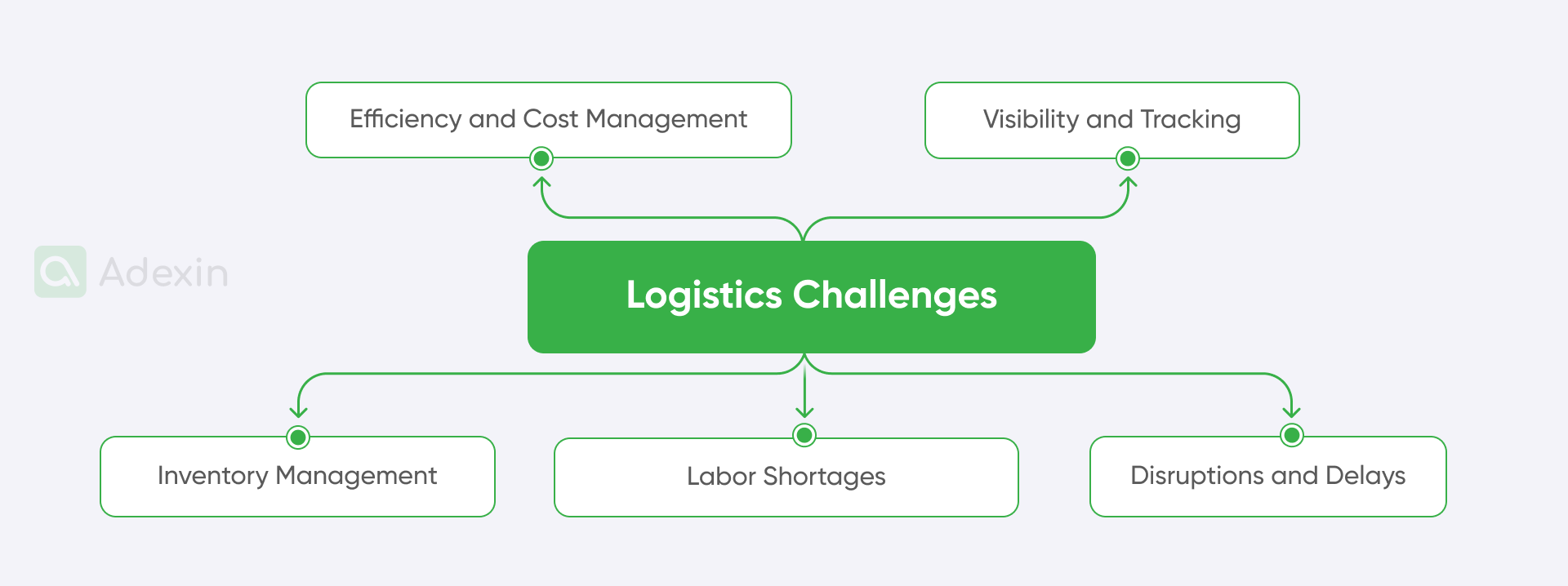

Logistics management challenges:

Efficiency and cost management. The first challenge is focused on optimizing transportation routes and warehouse space utilization. The logistics business runs on very small margins, so revenue strictly depends on a well-tailored pricing policy. There should be a balance regarding working hours, which means labor allocation to minimize costs and ensure timely deliveries.

Visibility and tracking. It's about keeping your customers informed about business transparency and making your actions visible to you. As a logistics manager, you must maintain real-time visibility of goods throughout the transportation network. This can be difficult and time-consuming without good software, such as a Fleet MS system or even a WMS system, especially for international shipments requiring complex supply chain insights.

Inventory management. Of course, the challenge is to strike the right balance between holding enough stock to meet demand and avoiding excessive inventory. In our article about logistics operations management, we have already written about FIFO, Just-in-Time, and Just-in-Sequence. All that management methods lead to storage costs and potential obsolescence that you don't want to.

Labor shortages. The growing demand for logistics services can be hampered. Hampered? Yes, it was very difficult in terms of how you handled people management. In some cases, you should invest in flex workers taken from the agency in peak seasons. Nevertheless, the skills are in the first place, and by a lack of skilled workers, like truck drivers (which is very common now) and warehouse personnel, you can lose your customers quickly.

Disruptions and delays. Things you cannot predict, like car accidents on the highway, can delay your shipping while your trailers are waiting in traffic jams. Moreover, unexpected weather disruptions, port congestion, or customs delays can significantly impact delivery schedules. Think about this as a big challenge that sometimes is even bigger when some work is based on paperwork instead of a well-settled document management system (DMS system).

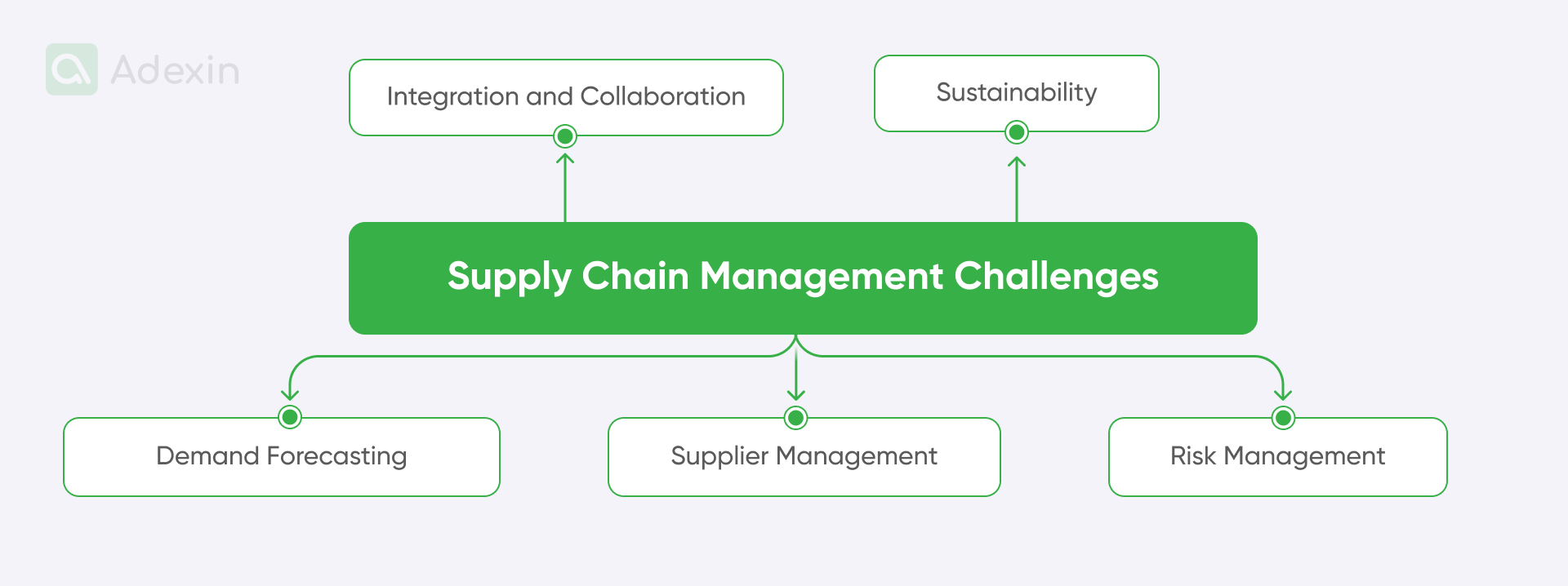

Supply chain management challenges:

Integration and collaboration. Coordinating and synchronizing activities across multiple companies and stakeholders. This is the top tier of Supply Chains but very difficult, especially within international trade, where you have slightly different approaches to handling shipments, laws, regulations, etc. This challenge is visible throughout the entire supply chain, and it can be complex. It tells us that SCM involves overseeing all that is going on from point A to B.

Demand forecasting. Another supply chain challenge is accurately predicting customer demand. To do this best, you need to overcome the challenges of dynamic market conditions, changing consumer preferences, and seasonal fluctuations. At the moment, the overall world economic situation and tensions in embargoes for some regions of the world are also having a huge impact on supply chain management.

Supplier management. Maintaining reliable supplier relationships and keeping good communication with all stakeholders is crucial. However, this challenge is again visible due to high diversification, not only based on the country but also related to technological advancement in the supply chain that some companies cannot cope with. So, the challenge is to ensure they can consistently meet quality and delivery expectations.

Risk management. Predicting what can happen in supply chains and how they are vulnerable to various risks is crucial to developing action plans and prevention. These issues in SC can include natural disasters, political instability, and raw material shortages. A good software development for supply chain management should mitigate these risks with proactive planning and contingency measures.

Sustainability. CO2 pollution and low regulations are pushing supply chains to be greener. Integrating sustainable practices throughout the supply chain is now crucial. Following ESG criteria (Environmental, social, and governance), such as reducing carbon footprint and minimizing waste, requires careful consideration and collaboration with many partners.

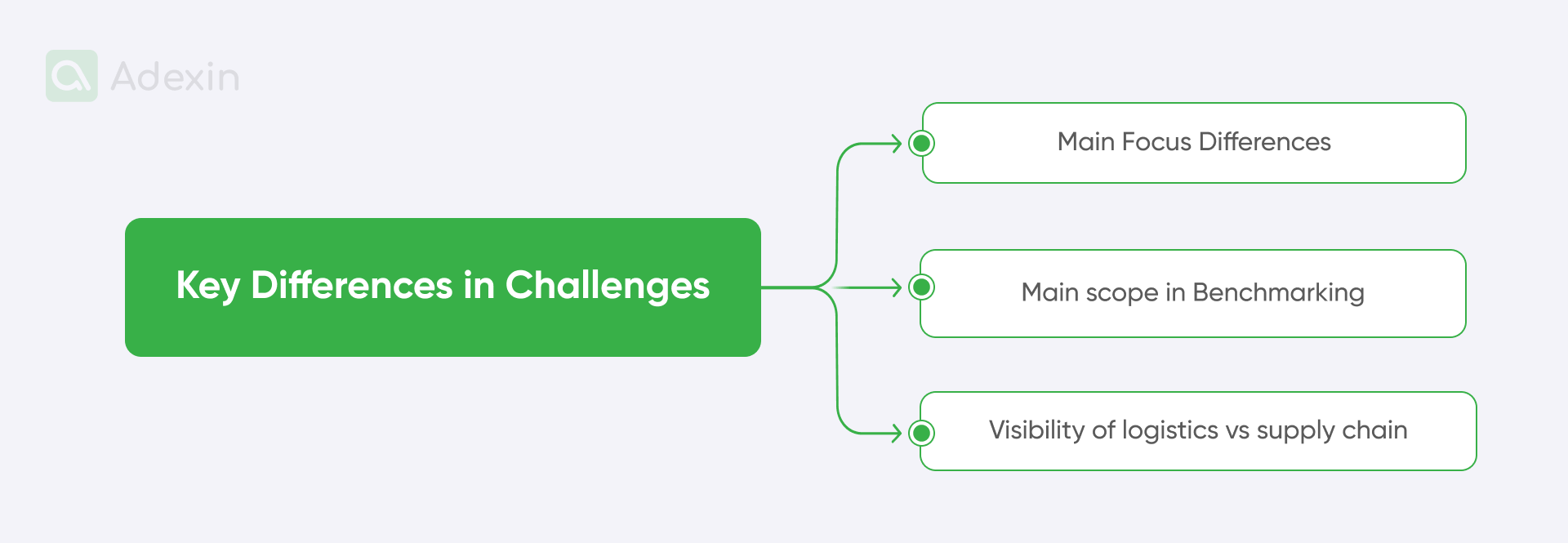

Key differences in challenges

Well, there is a crucial difference between these challenges in logistics and supply chain that can be difficult to spot. Below, we listed what is worth noting while benchmarking both areas of challenges for logistics and supply chain.

Main focus differences

Logistics challenges are more operational, and they focus on the efficient execution of moving goods within a specific timeframe and budget. Supply chain management challenges are more strategic. Here, you can see that they encompass broader planning and coordination across the entire product lifecycle.

The main scope of benchmarking

Logistics challenges primarily involve internal operations within a company or a specific supply chain section. So, they might be less saturated in terms of the number of stakeholders involved but still very complex in terms of processes. Supply chain management challenges involve a wider network of external companies and stakeholders. Here, you need to look at all those operations by mapping what is going on inside and outside the business.

Visibility of logistics vs supply chain

Well, it's important to see that logistics challenges deal with ensuring visibility within the transportation and warehousing processes. But, when we look at supply chain management, it requires broader visibility across the entire network. The supply chain goes from sourcing raw materials to delivering the final product. It is the whole logic, and we can specify this more based on certain examples.

You need to know that logistics and supply chain professionals can develop strategies to improve efficiency by understanding these unique challenges. They must mitigate risks and ensure smooth product flow throughout the ecosystem. This is also how you can gain a competitive advantage in your business operations.

For this purpose, these businesses are using various systems to improve their operations. One good example is the implementation of an assistance application for truck drivers. This is the case of one of our customers for whom we delivered full custom development for a logistics and transportation company. The application has improved and streamlined business processes, providing cost-effective services previously unattainable using existing tools.

Need help with custom software development for your logistics business?

Learn how we can help you

Explore moreFinale takeaway

We can say that we unpacked the distinct roles of these two players in your business. This article showed the fascinating logistics and supply chain management (SCM) world. We gave you a drawing based on our field experience and business process management expertise. We gave you a hint on how software solutions can streamline these crucial operations. So, we wanted to give you something that ensures efficient product delivery in both B2C and B2B environments.

We hope that you, as a small and medium-sized business, understand the distinct roles of logistics and SCM. Contact us if you're ready to explore how these insights can be applied to your business. With our knowledge, we can help you cost-effectively get on the right path and deliver your company's success, with increased customer satisfaction.