Well, you may know that it all begins with a single package. A forward journey from the warehouse to the doorstep of every person. This process should be so well-oiled and efficient that we barely give it a second thought. But what happens when the journey isn't a one-way street? What happens when that package, for a myriad of reasons, needs to turn around and head home?

This is the story of logistics management based on years of experience of our staff, the intricate, often chaotic, and increasingly vital world of reverse logistics. It's the journey of a returned sweater, a recalled car part, or an end-of-life electronic device. For years, this process was seen as an expensive afterthought. But there is an evil in the supply chain process. And the numbers tell a different story, a story of a booming industry poised for immense growth.

In 2023, the global reverse logistics market was a staggering USD 768.59 billion. Think about that for a moment, a market of nearly three-quarters of a trillion dollars built on the back of products moving in reverse. But that was just the beginning. Analysts project this market to grow from USD 801.64 billion in 2024 to a colossal USD 1,166.81 billion by 2032, exhibiting a compound annual growth rate (CAGR) of 4.8% during the forecast period.

This growth is not uniform across the globe. The narrative of reverse logistics is a distinctly American one. In 2023, North America stood as the undisputed leader, commanding a dominant 48.72% share of the total market. And the momentum isn't slowing down. The U.S. reverse logistics market, a powerful engine of this regional dominance, is projected to reach an estimated value of USD 358.36 billion by 2032.

This is more than just a market trend; it's a fundamental shift in how businesses view their products and their relationships with customers. The once-neglected return is now a cornerstone of customer satisfaction, a driver of sustainability, and a new frontier for innovation. This is the story of reverse logistics, and it's just getting started.

Key categories of reverse logistics

The reverse logistics process is a systematic approach to recovering value from returned products. It begins with collection, where items are retrieved from customers and brought to recovery points with strict inventory management control and reverse distribution. After inspection, products can be reused, resold, or redistributed. If they are as good as new, they can quickly return to the market to achieve higher business value. Recovered products then reenter the supply chain to improve customer satisfaction and outbound logistics.

Unlike the traditional supply chain, which focuses on delivering goods to customers, reverse logistics manages the efficient movement of products back to the company to a centralized processing center to recapture value or ensure proper disposal. This process is essential for modern businesses, offering a structured way to handle returns, extend product life cycles, and maintain sustainability.

What types of reverse logistics do we have? Let's see more below:

Customer returns. This is the most common type of reverse logistics, dealing with the return of products from customers for reasons like defects, dissatisfaction, or order errors.. It's focused on handling the entire process efficiently, from receiving the item to processing refunds, exchanges, or repairs, to ensure customer satisfaction.

Distributor returns. This deals with surplus stock that has not been sold or has had poor sales. It involves strategies to redistribute, discount, or liquidate this stock to recover some value and prevent it from becoming a complete loss.

Remanufacturing. Remanufacturing involves a thorough process of restoring a used product to a like-new condition. Unlike simple repairs, this process often includes replacing components and ensuring the product meets original specifications for quality and performance, thereby extending its useful life.

Refurbishment. Refurbishment is a less intensive process than remanufacturing. It involves making minor repairs and improvements to returned products, such as fixing cosmetic damage or minor functional defects, to make them suitable for resale at a reduced price.

Recycling. This type of reverse logistics is dedicated to the collection and processing of materials from used products. The goal is to reduce waste, to recover valuable materials, and reintroduce them into the manufacturing process for new products, which is a key practice for a circular economy.

Waste disposal. This is the final stage for products that cannot be reused, refurbished, or recycled. It focuses on the safe and compliant disposal of items to minimize environmental impact, adhering to all relevant regulations and standards.

Product recall. Product recalls are a critical type of reverse logistics for retrieving products that are found to be faulty or unsafe. This process is often mandatory and focuses on quickly and safely removing the products from the market to protect end consumers and the brand's reputation.

Top 5 challenges of reverse logistics

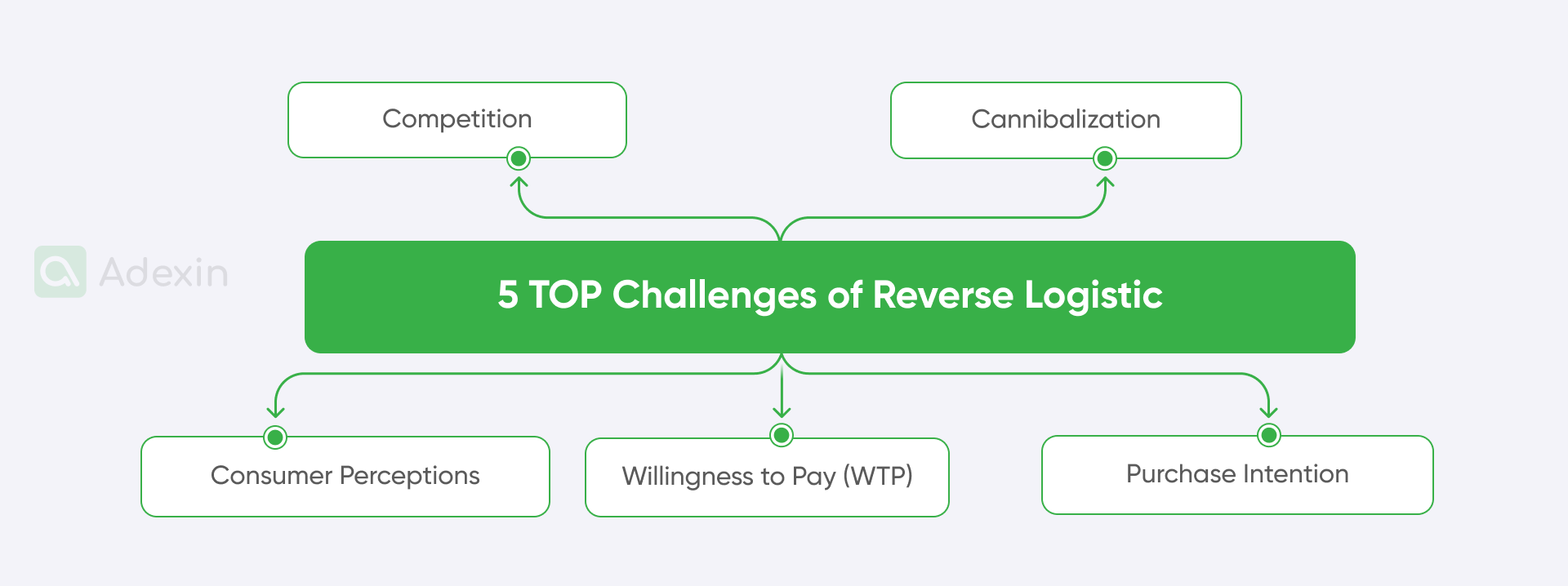

Challenges in reverse logistics research have historically focused on the supply side, such as collection and remanufacturing. However, future challenges are increasingly centered on the demand side, specifically how recovered products are reintroduced to the market. Researchers agree on the need for more interdisciplinary work with marketing and accounting to validate assumptions in closed-loop supply chain (CLSC) models. This new frontier explores how to effectively re-market recovered products.

Let's look at five major issues with reverse logistics:

1. Competition

This challenge examines how remanufactured products impact market competition. Studies show that direct competition between original equipment manufacturers (OEMs) can affect remanufacturing profitability. Remanufactured products can help an OEM compete for price-sensitive consumers. Some companies may even sell new products at a loss to create a supply for more profitable remanufacturing operations.

2. Cannibalization

Cannibalization is the risk that a remanufactured product sale will displace a new product sale. Many managers fear this, often without empirical evidence. Research suggests this risk is minimal in B2C markets but may exist in B2B markets. It's a key area that needs more empirical research to move beyond conventional wisdom.

3. Purchase Intention

Consumer purchase intention is influenced by a complex mix of factors. While lower price and environmental benefits are motivators, a surprising negative correlation exists between product knowledge and purchase intention. This is often due to consumer distrust of the remanufacturing process. Brand image and societal norms also play a significant role, with consumers more likely to buy a remanufactured product from a brand they trust. So, this is the way that helps build customer loyalty and decrease the impact when there is a delivery failure from fulfillment centers.

4. Willingness to pay (WTP)

Consumers generally have a lower willingness to pay (WTP) for remanufactured products because of perceived lower quality. Providing information about the product's environmental benefits can help, but it doesn't necessarily lead to a premium price. WTP varies significantly by product, for example, consumers are more willing to pay for recycled paper than for auto parts or electronic equipment.

5. Consumer perceptions

The core of these challenges lies in consumer perceptions. The ambiguity of the remanufacturing process (e.g., product age, component quality) leads to consumer mistrust and a reduced WTP. The identity of the remanufacturer (OEM vs. third-party) also influences perceived value. Marketing strategies must focus on key attributes like lower price and eco-friendliness to appeal to specific consumer segments and reduce the need for returns.

Need help with reverse logistics software for your business?

Learn how we can help you

Explore moreAccelerating reverse logistics with custom WMS solutions

Based on years of experience in logistics, transportation, and supply chain, at Adexin, we accelerate the reverse logistics process by leveraging our expertise in warehouse management system (WMS) development and its proprietary Adexin Tools Framework. The key is to integrate a comprehensive WMS that streamlines every stage of the returns management process journey.

Adexin's custom software includes features specifically for returns. By implementing a customized returns management feature, companies can effectively manage the influx of returned products. The use of a classification system like KLT (kind, length, and type of item or package) helps make the process more sustainable and efficient, which inherently speeds it up.

Let's look at the main software solutions that Adexin can develop to speed up reverse processes in companies:

Integrations of warehouse software

The guide highlights the importance of integrating a WMS with other technologies, such as barcode scanners, RFID, and packaging management. When a product is returned due to delivery refusal, these technologies can be used for rapid identification and data entry, immediately updating the inventory system. This removes the need for manual data input, which is a common bottleneck.

Improving product traceability

Adexin's software increases traceability of goods by tracking their movement from the moment they are received back in the warehouse. This is achieved using track-and-trace technology and digital proof of delivery (POD) within the product life cycle. In this way, the company is getting a competitive advantage and can truly save costs. Knowing the exact location and status of a returned item at all times reduces search time and eliminates errors, making the process faster and more accurate.

Implementation of the analytics function

Data-driven decisions are the key. The analytics and KPIs (key performance indicators) feature provides detailed dashboards with key metrics. By analyzing data related to returns, such as the most common reasons for return or the time it takes to process them, companies can identify and address inefficiencies. This allows for continuous process improvement, leading to a faster and more optimized reverse logistics flow.

Technology-driven reverse logistics solutions

Reverse logistics returns, repairs, refurbishment, and end-of-life recovery are the fastest routes to better margins and lower environmental impact. When done well, they return value, reduce waste, and extend product life. Up to ~40% of items can be salvaged in some flows. Digitization is the accelerator. Automated returns, real-time tracking, and data-driven consolidation cut handling time, lower miles driven, and reduce processing errors.

Below are three technology approaches that demonstrate how to speed up the reverse process in logistics, reduce costs, and improve sustainability performance.

1. Fully custom solutions

A fully custom reverse logistics platform is built around your flows, returns intake rules, condition assessment, disposition workflows, resale, repair, recycle, and carrier or routing logic. These reverse logistics systems can combine mobile apps for field collection, barcode and RFID scanning in warehouses, real-time vehicle and shipment telemetry, rules engines for automated dispositions, and analytics that forecast return volumes and identify bottlenecks. Custom systems maximize automation and consolidation, fewer trips, less idle time, and can embed sustainability KPIs directly into operational decisions. Expect higher up-front investment and a longer rollout, but the tight fit delivers the fastest throughput gains and best long-term ROI.

2. Hybrid solutions

Hybrid approaches extend existing TMS, WMS, and ERP platforms with custom returns modules and integrations. Instead of replacing core systems, you add targeted capabilities, automated returns routing, a returns portal, smart pickup batching, and APIs for third-party repair or remanufacturing partners. Hybrids are faster and cheaper to deploy than full rewrites, and they let you incrementally introduce features such as CO₂ or cost-per-return dashboards. The tradeoff is that integration complexity can create data silos if not developed carefully, so invest in a robust data model and middleware.

3. Existing solutions

Pre-built returns platforms and third-party reverse-logistics services offer the fastest time-to-value. They provide tested workflows, carrier integrations, and customer return portals out of the box. Off-the-shelf tools are ideal when you need quick wins like automated RMA flows and consolidated carrier pick-ups, but offer limited customization for specialized disposition rules, on-site inspections, or multimodal consolidation. Many companies start here and graduate to hybrid or custom as volumes and complexity grow.

Our solid reverse logistics plan, from mobile apps that streamline pickups to lightweight warehouse systems that digitize inspections and returns, demonstrates how these principles work in practice. Each tool embodies technology-driven design, operational efficiency, and proven results. Together, they show how companies can move from theory to execution, speeding up reverse logistics while boosting sustainability and customer satisfaction.

Trucker assistance application

We built trucker assist, a mobile Android and iOS app, plus a web portal that streamlines pickups, deliveries, and returns for U.S. trucking fleets. Features like real-time GPS tracking, automated paperwork and signatures, integrated payment and proof-of-delivery, status notification, and load logging. By removing manual steps and centralizing data, the app shortens dwell times, reduces errors, and accelerates reverse pickups and returns processing.

Lightweight warehouse management system

Our lightweight WMS is a scalable, barcode-ready system deployed across four warehouses for a MENA manufacturer. It digitizes inbound inspections, labeling, putaway, stock transfers, and returns workflows, plus audit history and reporting. Built-in inventory traceability and batch processing speed reverse flows, enabling faster inspections, smarter disposition like resell, repair, recycle, and reliable restocking, while reducing manual reconciliation and mispicks.

The high cost of manual reverse logistics

Reverse logistics, once considered an afterthought, has evolved into a vital and rapidly growing sector. The global market is projected to surpass $1 trillion by 2032, with North America leading the way. This growth reflects a shift in business strategy, efficient returns management is now essential for profitability, sustainability, and customer expectations and satisfaction.

Failing to implement digital solutions such as a warehouse management software (WMS) in reverse logistics creates a cascade of problems that erode profitability and customer trust. Without a structured, technology-enabled approach, the reverse supply chain process becomes chaotic and inefficient:

Manual processes and a lack of real-time visibility lead to costly delays and errors.

Even centralized return centers cannot fully mitigate human error or data gaps.

Products often sit in limbo with their status unknown, delaying refunds or exchanges.

This inefficiency not only damages customer satisfaction but also diminishes the resale potential of returned items. Companies are left guessing whether returned inventory will be resold, refurbished, or recycled. This uncertainty results in missed opportunities for value recovery and turns potential assets into liabilities. In effect, not embracing digitalization makes the reverse logistics process a drain on resources rather than a strategic advantage.

Technology-driven approaches are the foundation of a faster, greener, and more profitable reverse logistics process. When businesses combine digital visibility and automation with sound operational practices, they achieve measurable gains such as shorter return cycles, lower costs, and reduced environmental impact. Logistics examples include:

Enhanced visibility. Real-time GPS tracking, shipment updates, and scan events enable faster batching and dynamic re-routing of pickups.

Automated inspection and sorting. Barcode scanning and standardized grading speed up disposition decisions and restocking.

Transport consolidation. Planning multi-stop routes and batching returns reduces mileage and emissions.

Predictive analytics. Identifying high-return SKUs, forecasting peak periods, and pre-positioning repair capacity prevent bottlenecks and improve resource allocation.

Digital transformation in reverse logistics isn’t just about technology, it’s about transforming operations to unlock value. Companies that invest in data-driven tools and process improvements can recover more value from returns, strengthen customer loyalty, and achieve sustainability goals. Those that don’t risk falling behind face higher costs, lower efficiency, and eroded market competitiveness.

Are you in search of a reliable tech partner?

Adexin can help with advanced logistics solutions

Contact usFinal takeaway

The reverse logistics process is no longer a back-office burden, it’s a trillion-dollar opportunity to improve margins, sustainability, and customer loyalty. By embracing technology-driven solutions like custom WMS platforms, companies can automate returns, gain real-time visibility, and recover more value from every shipment. Don’t let manual processes drain profits or damage your brand. Contact us today to discover how a tailored WMS can turn returns into a competitive advantage.