Supply chain management digital transformation is about adapting modern, customized marketing and management tailored to technology in its broadest sense. This blog will reveal aspects of the digital supply chain management process and the benefits of digital transformation.

In 2026, supply chains are transforming not only for efficiency, but for resilience, regulatory compliance, ESG transparency, and AI-driven autonomy. After years of global disruptions, geopolitical instability, and supply shortages, digitalization is no longer a competitive advantage, it is a survival requirement. Companies now invest in end-to-end visibility, AI-powered planning, and autonomous execution to stay operational under constant uncertainty.

Today, we meet on the journey again, and based on our insights and firm market numbers, we present predictions for upcoming trends in digital transformation in logistics and supply chains in 2026. What has changed over the last year, and what advances in supply chain management now allow companies to customize their operations? You'll find the answers in this article. Join us on the journey, and let's dive deep into the recent trends in digital transformation across the value chain!

What is digital transformation in the supply chain?

The emergence of intelligent transportation systems drives the supply chain management digital transformation. These systems address the complexity of systemic barriers and help fully realize the benefits of business transformation. For example, as Logistics 4.0 unfolds, generating massive amounts of data presents opportunities and challenges. It is also tightly connected to better data management and usage, which must fully overcome existing obstacles. So to speak, digital transformation in the supply chain represents a paradigm shift in the digital world that is essential to boost operations.

Digital transformation for SC also involves the concept of digital supply chains. The digital transformation of supply chains involves integrating digital technologies into every aspect of supply chain operations. This isn't merely about digitizing existing processes; it necessitates a radical reimagining and reinvention of the supply chain to fully take control with the power of digital technologies.

As I already said, data is at the core of this digital revolution. By leveraging data-driven insights, supply chains can make informed decisions, along with more optimized operations, and last but not least, improve overall performance (here we can see a major shift in KPIs management). This approach can range from employing IoT devices to track inventory in real-time to utilizing AI and machine learning to automate repetitive tasks. Advanced analytics can also be used to forecast demand more accurately.

In practice, digital transformation in the supply chain means implementing control towers, end-to-end visibility platforms, digital twins of logistics networks, AI-driven demand planning, and autonomous execution systems that connect procurement, warehousing, transportation, and last-mile delivery into one data-driven ecosystem.

Top 20 areas of digital supply chain transformation for 2026

Digital transformation in moving around these areas:

#1. Last-mile delivery optimization improves efficiency and customer satisfaction in final-mile delivery for diverse business models. It involves strategies such as route optimization, real-time tracking, and flexible delivery options to meet the specific needs of different industries, from e-commerce to healthcare. Companies can enhance customer satisfaction and reduce operational costs by refining delivery routes and minimizing delivery times.

#2. Ubiquitous sensing enables autonomous vehicles to perceive and respond to their surroundings, enhancing safety and efficiency. By processing this data in real-time, autonomous vehicles can make informed decisions, avoid obstacles, and navigate complex traffic situations. It leads to safer and more efficient transportation, particularly logistics and delivery operations.

#3. Cloud computing. Leveraging scalable and flexible cloud infrastructure for logistics operations, reducing costs, and improving agility. By utilizing cloud-based solutions in 2025, businesses can reduce IT infrastructure costs. We have already seen how it improves operational efficiency and enhances team collaboration. Gartner forecasts that over 95% of new digital workloads will be deployed on cloud-native platforms by 2025, up from 30% in 2021.

#4. Augmented reality. Enhancing warehouse and logistics operations through real-time visual information and guidance.

#5. Advanced analytics. Utilizing data-driven insights to predict future trends, optimize decision-making, and improve logistics performance. By providing real-time guidance, augmented reality can improve accuracy. We're also talking about higher speed and worker productivity in warehouse environments.

#6. Edge devices. Processing data closer to the source for faster response times and reduced network latency. Keep in mind that edge devices can improve system performance and reduce network congestion by offloading processing tasks from the cloud.

#7. AI and machine learning. AI agents and applications for strictly automating tasks and optimizing processes are improving decision-making in logistics and supply chain management. We see this as a trend for whole areas far beyond SC and logistics.

#8. Blockchain. Ensuring transparency, security, and traceability in supply chain transactions, this all sounds repetitive, but blockchain technology provides an immutable and transparent ledger of transactions, making it ideal for tracking the movement of goods throughout the supply chain.

#9. Private 5G and satellite connectivity. In 2026, logistics operators will increasingly rely on private 5G networks and satellite internet for uninterrupted real-time data exchange in ports, remote areas, and cross-border corridors. This ensures stable connectivity for autonomous vehicles, cargo monitoring, and control towers.

#10. Smart warehouse management involves optimizing warehouse operations through automation, IoT, and data analytics. By looking back again at the data, businesses can optimize warehouse layouts. Further, it is about improving inventory management and enhancing overall efficiency.

#11. Additive manufacturing. Here, companies in the supply chain will focus more on producing goods on demand. This will reduce inventory and improve supply chain flexibility.

#12. Drone operations. Efficiency in delivering goods is paramount. Today, we see numerous experiments with drone deliveries, especially in remote or congested areas. This trend also shapes the digital transformation expected in 2025.

#13. Robotics and dark warehouses. Automating warehouse operations improves efficiency and reduces labor costs. Robots can perform tasks like picking, packing, and transporting goods with greater accuracy and speed, leading to increased efficiency and reduced labor costs.

#14. Wearable computing. Enhancing worker productivity and safety through real-time information and task guidance. Wearable devices like smart glasses and watches can provide workers with real-time information, such as picking lists, inventory levels, and quality control guidelines.

#15. Big data analytics. Leveraging large datasets to identify trends, optimize processes, and improve decision-making. Businesses can gain valuable insights into their operations by analyzing vast amounts of data from various sources, such as IoT devices, sensors, and supply chain systems.

#16. Smart logistics and supply chain management. We focus solely on integrating digital technologies to optimize logistics operations and improve supply chain visibility.

#17. Procurement 4.0. Utilizing digital technologies to optimize sourcing is crucial for freight forwarders and distribution centers that experience high order fluctuations. As a result, procurement software platforms for managing supplier relationships are becoming more frequently used.

#18. IoT and smart transportation. As businesses get more complex due to the growing number of high-tech hardware applications, today's connecting devices and vehicles to collect and analyze data are crucial for improved efficiency and safety. We mentioned this above, but it's worth reiterating at the top.

#19. Cargo monitoring and digital containerization. The focus of digital transformation is on improving the tracking and monitoring of cargo shipments. This all needs to be handled in real-time to improve visibility and security.

#20. Autonomous control towers. In 2026, supply chains will increasingly rely on AI-powered control towers and autonomous agents that continuously monitor operations, predict disruptions, and automatically trigger corrective actions across procurement, warehousing, transportation, and last-mile delivery. These systems enable real-time decision-making with minimal human intervention and significantly improve resilience and response speed.

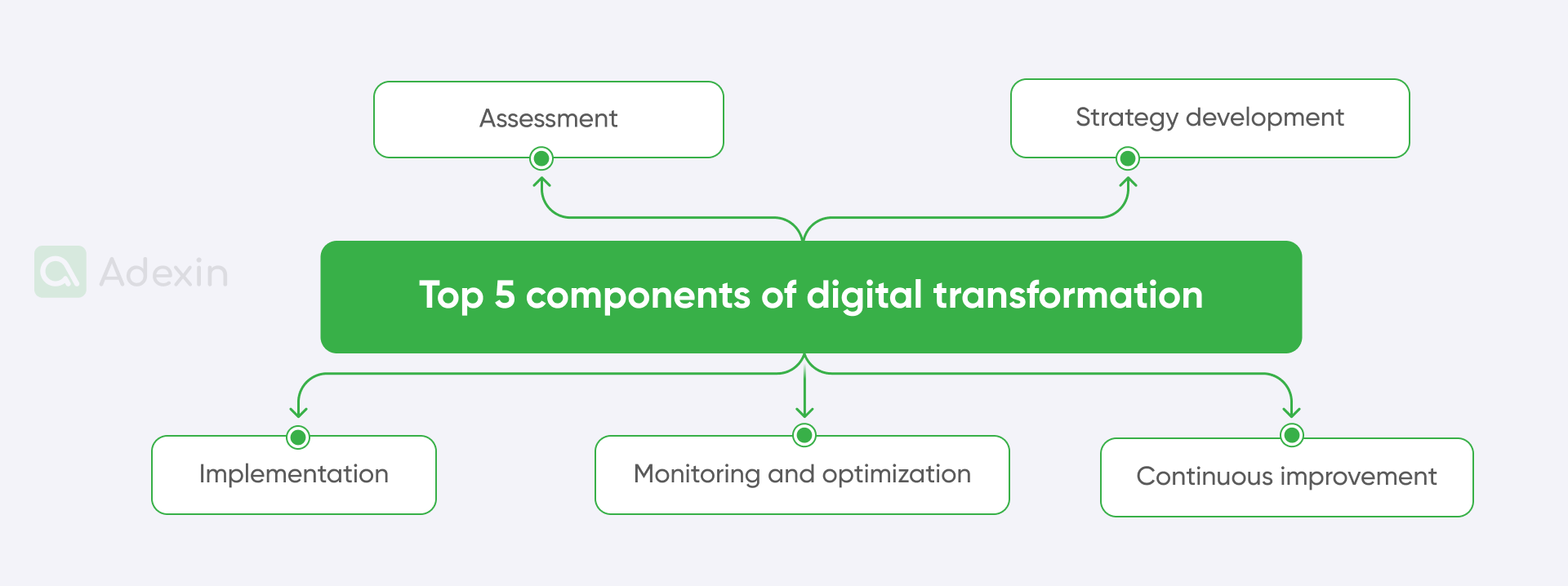

5 steps of the digital transformation process in the supply chain

Digital supply chain management involves a series of steps requiring careful planning and execution. It's not just about implementing new technologies but also changing how the organization operates and thinks.

Here are the critical steps involved in this process:

1. Assessment. The first step in the digital transformation process is to assess the current state of the digital transformation of the supply chain. It involves understanding the existing processes, technologies, and capabilities and identifying the gaps and areas for Improvement. This step also involves understanding the business objectives and aligning the digital transformation strategy with these objectives.

2. Strategy development. Once the assessment is complete, developing a supply chain strategy is next. It involves defining the vision and objectives of the transformation, identifying the key technologies to be implemented, and outlining the roadmap for the transformation. The supply chain planning and strategy should also include a plan for managing change and ensuring buy-in from all stakeholders.

3. Implementation. The implementation phase involves deploying the identified technologies and transforming the existing processes. It could involve implementing a new supply chain digital transformation, integrating IoT devices for real-time tracking, or leveraging AI and machine learning for predictive analytics. This step also involves training the staff on the new technologies and processes.

4. Monitoring and optimization. Once the new technologies and processes are in place, it's important to monitor their performance and make necessary adjustments. It could involve tracking key performance indicators (KPIs), conducting regular audits, and continuously optimizing the processes for better efficiency and effectiveness.

5. Continuous improvement. Changes in supply chains are not a one-time project but a continuous journey. It's important to stay updated with the latest technologies and trends and continuously improve the supply chain processes to stay competitive.

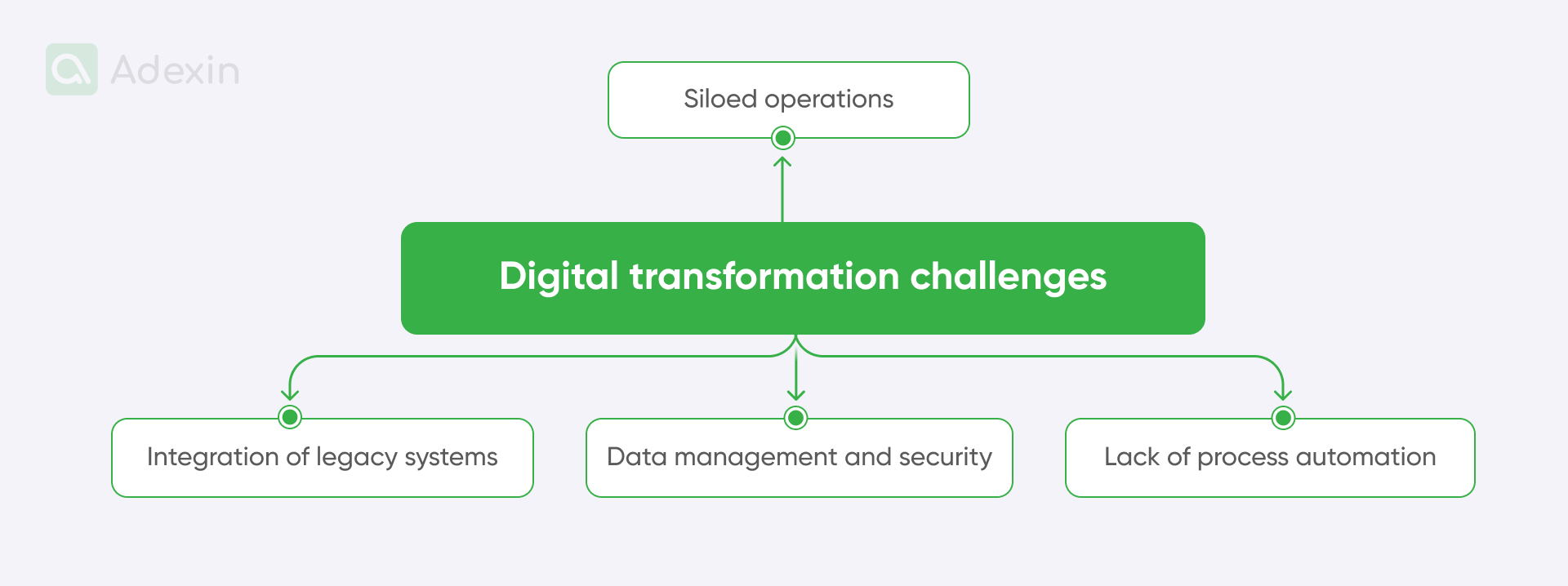

Key resistances to implementing digital transformation in the supply chain

Implementing digital transformation in the logistics and supply chain can come with several challenges. These could include resistance to change, lack of digital skills, data privacy and security concerns, and high costs of implementation. Here, you should pay attention to the Research on the Influence of Supply Chain Finance on Enterprise Operation Performance Under the Background of Digital Transformation.

So, let's look at what resistances are most often encountered:

Overcoming resistance to change

Change can be unsettling for many people, and employees who are comfortable with the existing processes may resist it. This can be overcome by communicating the benefits of the transformation, providing adequate training, and involving the employees in the transformation process.

Addressing skill gaps

Digital transformation often requires new skills that the existing staff may not possess. It can be addressed by providing training and development opportunities, hiring new staff with the required skills, or partnering with technology providers who can provide the necessary expertise.

Ensuring data privacy and security

With digital transformation, the amount of data collected and processed often increases, raising concerns about data privacy and security. For example, data authorization access is quite important in this context. When you're using paperwork in your warehouse management and exchanging it with carriers, you may need a document management system (DMS). The DMS can use single authentication for each user who wants to access documents, so not everyone who was previously handling shipping documents will be able to see their content. It is crucial, especially with high-value cargo, to protect your customers against theft.

Managing costs

Implementing new technologies can be expensive. However, the cost can be justified by the long-term benefits of increased efficiency, improved customer service, and competitive advantage.

The best way to assess if you can get ROI is to map out all your operations to determine where they actually bring value by digital transformation value chain creation. In most cases, there are tangible and intangible values, but in one way or another, they can be measured based on financial outcomes.

When we implemented a mobile app for truckers, the first step was to satisfy a reasonable management assessment. In the second tier, we truly helped truck drivers in their daily work, but it wasn't measured in any way. We heard that they were satisfied, but you can also put more emphasis on this and see what the intangible ROI is.

Need help with custom mobile app development?

Learn how we can boost your logistic business processes

Explore moreWhat are the supply chain digital transformation challenges for 2026? Is inflation a risk?

We're talking a lot about system challenges and technology, but we need to focus on how inflation can affect supply chains. Of course, by deploying technology, we can also overcome inflation challenges. In 2026, the main risks for global supply chains are increasingly shaped by geopolitical conflicts, sanctions, trade restrictions, reshoring strategies, and regulatory fragmentation, rather than inflation alone.

And at the same time, inflation can significantly impact supply chains:

Increased input costs. Rising prices for essential materials like energy can erode company profits.

Price adjustments. Companies need to focus more on maintaining profitability, so there is no doubt that companies may need to increase their product prices and services, which in SC can be distribution costs and transportation.

Needs for strategic negotiation. Organizations need to develop better negotiation skills to proactively address supplier price increases by employing negotiation strategies. McKinsey outlined this in their report from 2022, which also outlines recent developments for 2025.

However, moving on a digital transformation journey has its challenges. Companies often need help with resistance to change, data security concerns, and the need for significant upfront investment. Based on our experience, we know what challenges companies can face while adopting new solutions. We have already handled many projects in which we introduced new business approaches to companies according to their expectations.

A good example of such a project was our participation in the development of a shipping document management platform. In this project, we took into account all the customer requirements, and our team was involved in the development of custom software for the document management system for eTEU. EU is a digital platform that makes creating, editing, and sharing documents easy through an easy-to-use management system.

As with any project, including this one, there were many challenges. Considering challenges from this project and others we have successfully overcome, we outline several major obstacles while moving in digital transformation in the supply chain.

The initial catalyst for this project was effective change management. This ability to adapt and pivot is a significant challenge for supply chain organizations in 2025. A robust change management strategy is crucial to ensuring the transformation is completed successfully, as the final 20% of paper-based processes often prove to be the most difficult to eliminate. Organizations can inspire employees at all levels to fully embrace a paperless future by prioritizing change management.

Here, we outlined several other challenges for 2026:

Siloed operations in supply chains

The lack of integrated supply chain technology between a company's systems and processes is a significant obstacle for companies that want to start digitizing. Every company needs to address this in advance. Siloed operations hinder effective communication and collaboration between departments, leading to inefficiencies and chaotic processes.

You need to think ahead to 2025 and plan for the complete operational transformation. For example, according to McKinsey research, we can share a case of a chemical company that historically responded to commodity price drops by downsizing and cost-cutting, which often led to organizational upheaval and short-lived results. Along with the cross-functional transformation, the company successfully weathered a 20% commodity price decline while maintaining a 40% EBITDA margin (a financial metric that measures a company's operating profitability). This transformation also positively impacted employee engagement and business wellness.

For the next example, we want to share closely the case of warehouse management operations that should be integrated with shipping in the context of loading capabilities. Previously, companies could only recognize a fraction of the information carriers that had been handed to distribution centers. It was like telling warehouse personnel something like, "Okay, we have space for one euro pallet on the trailer." Still, the lack of communication between truck drivers, the control tower, and its carrier transit planner showed that the trailer was complete when the truck arrived.

It is only a very small example of how businesses faced communication problems, but could not measure everything without asking anybody. A better solution is for anyone to see that there is still room for an extra pallet in the truck instead of just assuming it may be possible. Overcoming supply chain challenges while embarking on the digital transformation can increase supply chain visibility.

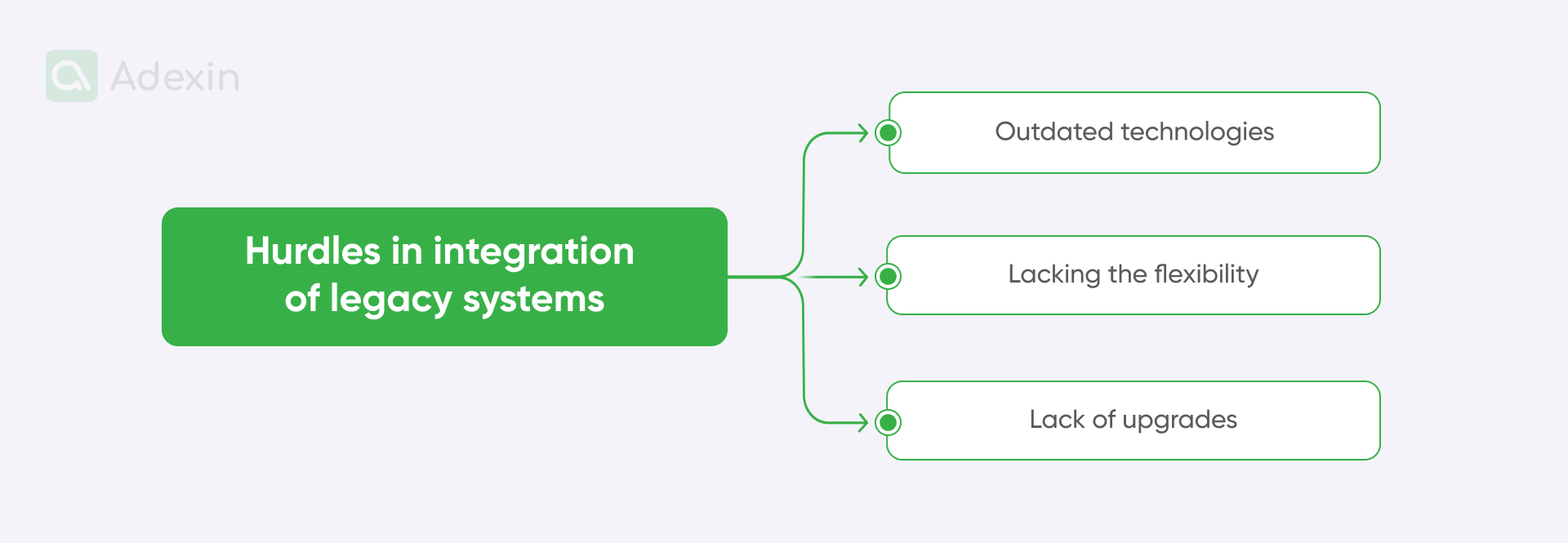

Integration of legacy systems

Organizations often need help with the complexity of integrating new digital technologies with existing legacy systems. This clash between old and new can hinder a smooth digital transformation. Older systems, often built on outdated technologies, can be rigid, lacking the flexibility needed to adapt to the demands of modern digital solutions.

Many organizations still operate on legacy ERP systems, including older SAP versions. In 2026, the focus is shifting toward API-first integration, migration to SAP S/4HANA, and cloud-based iPaaS platforms that enable gradual modernization without full system replacement.

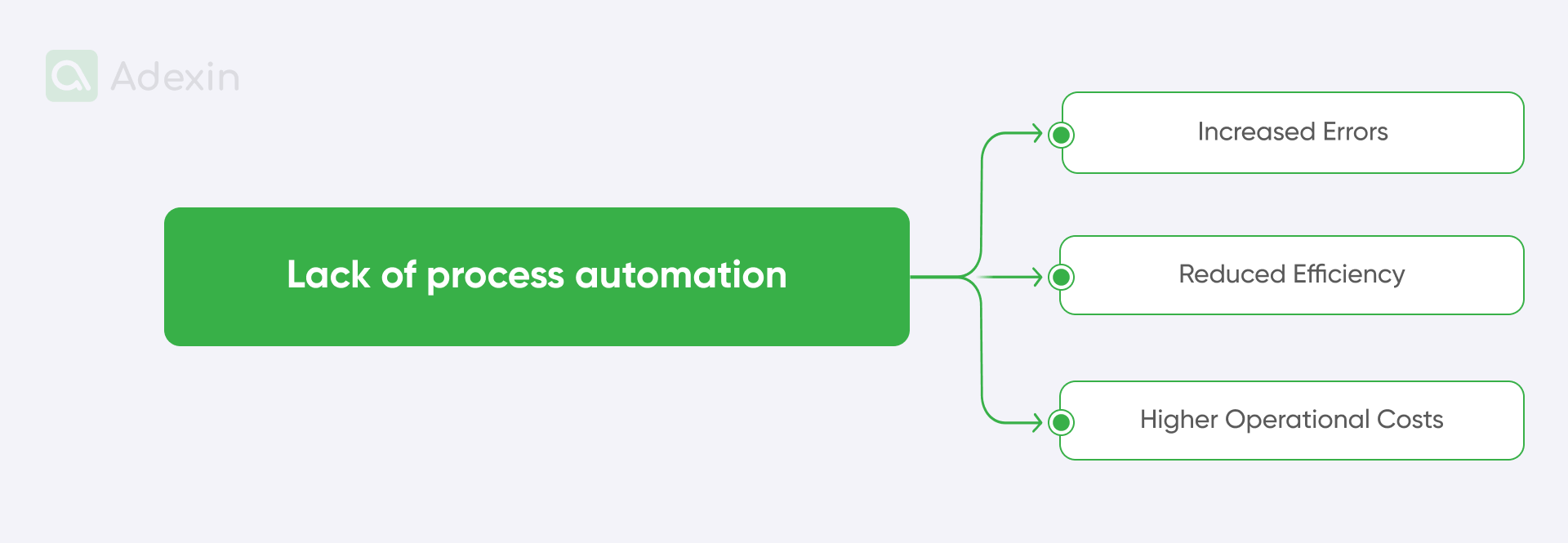

Lack of process automation

Without automated processes, companies have difficulty streamlining operations and fully utilizing digitization's benefits. Manual processes are prone to errors, delays, and inefficiencies, making it difficult to be productive, respond efficiently to market demands, and manage market segmentation.

McKinsey's recent Research indicates that 61% of respondents have achieved their automation goals. It underscores the importance of identifying the key factors contributing to successful automation. Notably, two-thirds of respondents are actively piloting automation initiatives in various business units or functions, a significant increase from the previous survey's 57%. This trend strongly suggests that the digitalization of supply chains will be a critical focus for 2026.

For example, companies that have adopted autonomous vehicles can minimize manual input in digital transformation projects. While working in the warehouse at the receiving station, which may still require people to book newly arrived stock with barcode scanners, autonomous vehicles can take care of the putaway process. It can save a lot of time, but also minimize the need for people to travel in the halls between shelves in the warehouse. It is where hundreds of injuries happen, as there is little space for moving around.

Data management and security

Proper data management and security measures are critical to a successful digital transformation. Data breaches, cyber-attacks, and privacy violations can damage reputations, incur legal consequences, and undermine customer trust. Organizations must invest in robust cybersecurity measures and establish a comprehensive data governance framework to mitigate these risks.

In 2026, most supply chain organizations will adopt a Zero Trust security architecture, AI model protection, and strict data residency policies to protect operational data and prevent large-scale cyber incidents.

Since data is integral to every decision, interaction, and process, companies that leverage data effectively will gain a significant competitive advantage. Organizations already realizing a 20% EBIT contribution from AI are more likely to prioritize data practices that support these capabilities. Based on these insights from McKinsey, data management will be a critical factor in driving success in 2025.

For example, data authorization access is quite essential in this context. When you're using paperwork in your warehouse and exchanging it with carriers, you may need a document management system (DMS), and there is no need for any mass customization of your internal systems. The DMS can use single authentication for each user who wants to access documents, so not everyone who previously handled shipping documents can see their content. It is crucial, especially with high-value cargo, to protect your customers against theft.

"Leading the logistics industry into a climate-neutral future is a Herculean task to which we have given top priority as the Group's management team. In addition to long-term decarbonization goals, what counts most is what we can do in the here and now – in a pragmatic and goal-oriented manner." (…) -

Dr. Tobias Meyer, CEO of DHL Group

By embracing this trend, companies can unlock new opportunities for mass growth and innovation while also building a more sustainable and resilient supply chain for the future. As we move forward, it will be exciting to see how this transformation continues to evolve and shape the future of supply chain management.

Digital transformation in the supply chain and adaptation of green practices in 2026

Navigating the dynamics of digital technology is a current trend, reshaping the landscape of mass-scale global management and performance. As we navigate the digital era, companies increasingly recognize the importance of leveraging technology to streamline their supply chain operations. The mainstream today is leading in the area of green transition and sustainability.

For example, fast-moving consumer goods (FMCG) companies are leading the way to a sustainable future by revolutionizing their supply chains. Referring to McKinsey research, Henkel, a well-known German consumer goods company, is an example of this approach. By prioritizing sustainability, Henkel's Laundry & Home Care business has achieved a remarkable 65% reduction in its carbon footprint over the past 15 years. It is, with no doubt, a remarkable achievement that has been accomplished while increasing operational efficiency. And all that alongside reducing costs and minimizing environmental impact.

In 2026, sustainability initiatives are increasingly driven not only by corporate strategy but also by mandatory regulations such as CSRD reporting, Scope 3 emissions tracking, CBAM, and the upcoming Digital Product Passport in the EU.

Undoubtedly, companies that become early adopters are in a far better position than their competitors. The first to adopt technology has a significant advantage in any competitive landscape. Some technologies are fully compatible even in the early stages, so getting on that train before anyone else is much better.

These results are fairly high compared to the past several years. Thus, this shows that transformation is not merely a buzzword, for many companies, now, it's a strategic imperative that can drive efficiency, enhance transparency, and foster innovation in a rapidly evolving marketplace.

The role of supply chain digital transformation

Supply chain digital transformation and its management are multifaceted. One key role is enhancing visibility across the supply chain. With digital supply chain technologies, businesses can track and trace products in real-time, from the raw materials stage to the end consumer.

As outlined in McKinsey reports, supply chains of the future will prioritize agility, robustness, and sustainability. As product lifecycles accelerate, a hybrid "push-pull-flush" model is gaining traction with annual new product introductions in retail.

This model combines an initial "push" phase for the first three months, a "pull-based" approach for the next six months, and a final "flush" period of three months to prepare for the next iteration. This dynamic approach empowers supply chains to adapt to rapidly evolving consumer preferences and to be an answer to market conditions.

Understanding the impact of digital transformation and its most important role for supply chain leaders is improving efficiency. By automating routine tasks, businesses can free up their staff to concentrate on more strategic, value-added activities. Moreover, digital technologies can streamline processes, reduce errors, and increase productivity.

You can gain many benefits from digital transformation, but it is important to understand its role. According to recent Research titled Digital transformation: fresh insights to implement green supply chain management, eco-technological innovation, and collaborative capability in the manufacturing sector of an emerging economy", digital transformation plays a crucial role in implementing green supply chain management and eco-technological innovation. It highlights the potential of digital transformation to enhance environmental sustainability and competitiveness in the manufacturing sector.

In this context, supply chain software development plays a crucial role. These processes involve creating customized digital solutions designed to optimize various aspects of the supply chain, from procurement and inventory management to logistics and customer service. The goal is to create a fully integrated, end-to-end system that is more efficient and responsive to variations in supply and demand.

Working with a supply chain software development company can provide businesses with the expertise and resources they need to implement these digital solutions successfully. These companies specialize in developing software applications that leverage technologies such as artificial intelligence (AI), enhanced cloud computing, and blockchain supply chain operations.

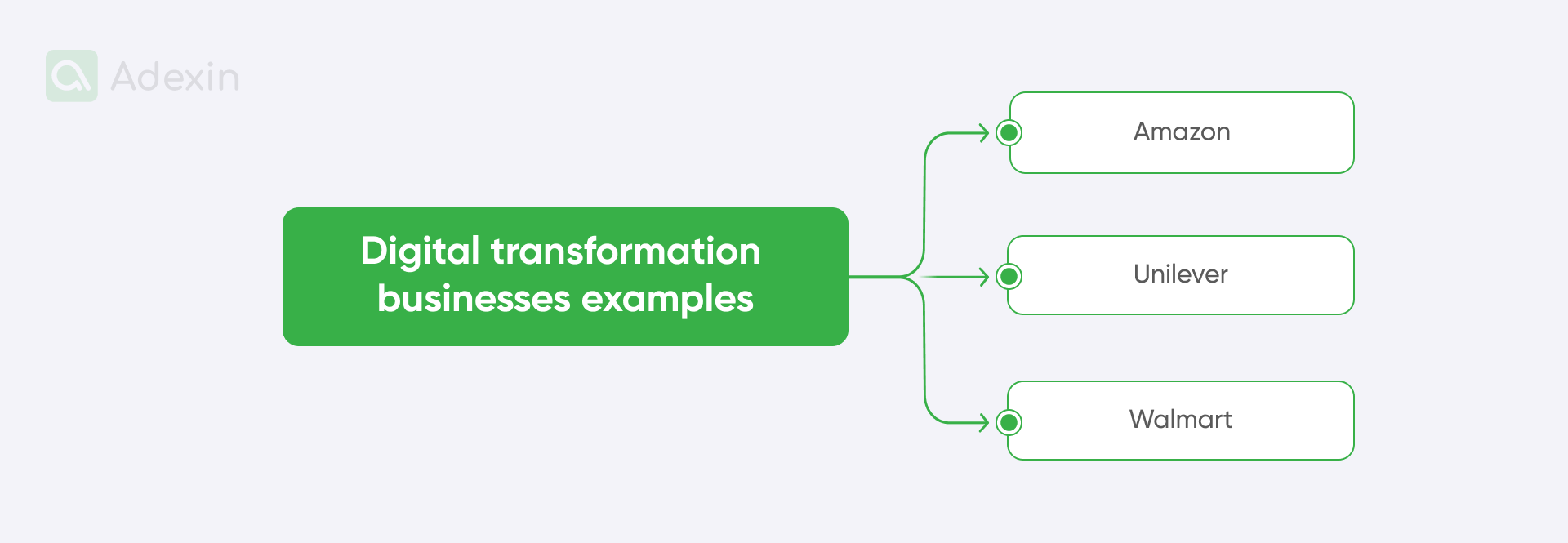

Examples of digital supply chain transformation

Digital supply chain transformation is a pivotal aspect of modern business operations. By leveraging digital technologies, companies can streamline their supply chain processes, improve efficiency, and enhance individual customer satisfaction. Here are a few real-world examples of an individualized approach from companies that have successfully implemented digital transformation in their supply chain.

Amazon and its entire supply chain ecosystem

Gartner forecasts a significant surge in mass-scale global cloud industry spending, projecting a 41% increase from $257 billion in 2020 to $364 billion in 2022. This growth is evident in the strategies of e-commerce giants like Amazon, which has leveraged advanced digital tools powered by AI, ML, and robotics to automate warehouse operations, all underpinned by cloud technology. This automation has increased efficiency, reduced errors, and faster delivery times. Amazon's supply chain is also highly adaptable, enabling it to respond swiftly to fluctuations in demand.

Unilever with global supply chains

Unilever, a leading global consumer goods company, is at the forefront of sustainable supply chain innovation. The company is actively working to achieve its 2025 goal of making all plastic packaging reusable, recyclable, or compostable and incorporating at least 25% recycled plastic. Additionally, Unilever aims to reduce virgin plastic usage by 50% within the same timeframe. By implementing advanced technologies, Unilever has reduced its carbon footprint and enhanced overall supply chain efficiency.

Walmart's digital transformations and green transition

Walmart's recently released 2025 Commitments Fact Sheet highlights the company's strong focus on sustainability. As the first retailer with a Science Based Targets Initiative-approved emissions reduction plan aligned with the Paris Agreement, Walmart aims to reduce operational emissions by 18% by 2025 through energy efficiency measures and renewable energy adoption. Additionally, Walmart has embraced digital transformation to optimize inventory management by integrating customized marketing tools, demonstrating its commitment to leveraging technology for sustainable growth.

These examples demonstrate the transformative power of digital technologies in the supply chain. By embracing digital transformation, companies can improve their operational efficiency, gain a competitive edge in the market, and better tackle market segmentation.

Companies need to invest in upskilling their workforce, redesigning their processes to leverage digital technologies, and implementing the right technologies to deliver tangible business benefits. A recent study titled Research on Digital Transformation of Supply Chain Finance provides an interesting perspective on the supply chain digital transformation.

We don't necessarily need to provide examples; everything should be clear. If you have personnel working on inbound tasks who aren't particularly computer-savvy, their work can become error-prone over time. So, don't expect that digital solutions and mobile applications alone will help you avoid complete errors. You need people who can adapt. Similarly, regarding skills, even if your personnel aren't computer-savvy, they should be willing to upskill their work capabilities to use mobile apps, etc.

The future of digital transformation in the supply chain

The future of digital supply chain management is a topic of great interest and importance. As we move further into the digital age, the supply chain industry is poised to undergo significant changes driven by technological advancements and consumer behavior shifts.

One of the key trends in this area is the increasing use of artificial intelligence (AI) and machine learning (ML). These technologies improve efficiency, reduce costs, and enhance decision-making processes. For instance, AI in the supply chain can predict demand patterns, optimize inventory levels, and identify potential supply chain digital transformation disruptions before they occur. Machine learning, on the other hand, can analyze large amounts of data and identify patterns that humans might miss. It can lead to more accurate forecasting and better decision-making.

Another major trend is the rise of blockchain technology. Blockchain can provide a secure, transparent, and immutable record of all transactions in the supply chain digital transformation, from the raw materials to the final product. It can help to reduce fraud, improve traceability, and enhance accountability. Moreover, blockchain can also facilitate smart contracts, automating certain processes and reducing the need for intermediaries.

The Internet of Things (IoT) is another technology to transform the supply chain industry. McKinsey's recent survey indicates that 98% of respondents prioritize enterprise IoT initiatives in their strategic plans. Companies must implement an integrated program that drives value across the entire business to fully capitalize on these initiatives. IoT devices, capable of real-time data collection and transmission, offer valuable insights into the status of goods, equipment conditions, and process efficiency.

Also, digital twin technology in supply chain management involves creating virtual copies of physical supply chain assets and managing them in real-time. It can help improve operational efficiency, reduce waste, and enhance customer satisfaction. These trends are expected to have a profound impact on businesses and the industry as a whole.

Companies that can adapt to these changes and leverage these technologies effectively will likely gain a competitive advantage. They can operate more efficiently, make better decisions, and provide more customer service. However, these changes also pose challenges. Companies must invest in new technologies, train their staff, and adapt their processes. They will also need to navigate regulatory issues, manage cybersecurity risks, and deal with the cultural changes that come with digital transformation.

A recent research paper, Digital Transformation and Supply Chain Relationship-Based Transactions discusses the impact and mechanism of corporate digital transformation on supply chain relationship transactions. It provides insights into how digital transformation can alleviate information asymmetry and agency costs, thereby reducing the degree of supply chain relational transactions.

Are you in search of a reliable tech partner?

Adexin can help with advanced logistics solutions

Contact usFinal takeaway

The blog post has comprehensively explored the importance and benefits of digital supply chain management processes. The key points discussed revolve around embracing digital technologies to enhance efficiency, improve accuracy, and foster innovation in supply chain operations.

We encourage all readers to embrace digital transformation in their supply chain processes. It may seem daunting initially, but the benefits are worth the effort. Remember, the digital transformation journey is not a sprint but a marathon. There are no short-term results. Get to know more, get in touch with us, and let's talk about transforming your business together.