Trends in the supply chains aren't a temporary fad. The entire supply chain industry is undergoing a massive transformation toward digital solutions. The entire management approach in the supply chain is shifting, revealing thoroughly new trends in supply chain management.

In 2026, supply chains will no longer be focused only on digitalization. Businesses now expect supply chain systems to be predictive, resilient, and capable of operating under constant disruption. Geopolitical instability, regulatory pressure, rising costs, and data transparency requirements are forcing companies to rethink how supply chains are designed and managed.

Artificial intelligence has moved from experimentation to practical adoption in supply chain management. In 2026, AI will be embedded into planning, forecasting, execution, and risk management processes, helping companies make faster decisions, reduce uncertainty, and respond to disruptions in real time.

Discover the trends poised to reshape the supply chain landscape in 2026. Learn about recent developments in the business and the future of supply chain management. If you are managing supply chains, this article provides actionable insights for future strategies. Our findings are built on years of experience in software development for the supply chain industry.

What is the supply chain market outlook for 2026 and beyond?

We see 2026 as a more strategic approach by many stakeholders, where much higher diversification of sourcing and routing leads to the need for developing procurement strategies. This is not the only single driver, but it is facilitated by real business needs. Looking ahead in 2026, companies are expected to focus on several core priorities that shape modern supply chain strategies:

Investment in technology

Investing in technology can significantly boost a business's efficiency and competitiveness. Companies will adopt innovative solutions more broadly, such as AI-powered tools, where we can analyze vast amounts of data to identify trends, optimize operations, and personalize customer interactions. Recent developments in technology integration show that nearly 72% of companies have implemented end-to-end supply chain planning.

Building strategic partnerships

PwC.com strongly predicts that strategic partnerships will also be leading in 2026. Integrating them into the supply chain can provide numerous benefits, such as access to new markets, shared resources, and reduced costs. This aligns with an example given by 47% of leaders who have implemented certain solutions that provide more transparency with partners. By collaborating with other businesses, companies can strengthen their market position and increase their resilience to economic fluctuations.

Optimizing business processes

Optimizing business processes involves identifying and eliminating inefficiencies to improve productivity and reduce costs. Key techniques for process optimization include implementing warehouse optimization tools or Lean Manufacturing, a methodology focused on eliminating waste and maximizing value within the supply chain. A good example can be drawn from PwC.com research, where 42% of companies that have already implemented planning using omnichannel order management have seen significant benefits over the last year.

Today's trends in the supply chain tell us that digitizing is an absolute must. No matter where a company is, you should be aware that your competitors, who are early adopters of some of the new capabilities and trends, will most likely already be better adapted to future challenges.

So don't lose your chance to see where you might expect developments and where you may consider future investments in supply chain management.

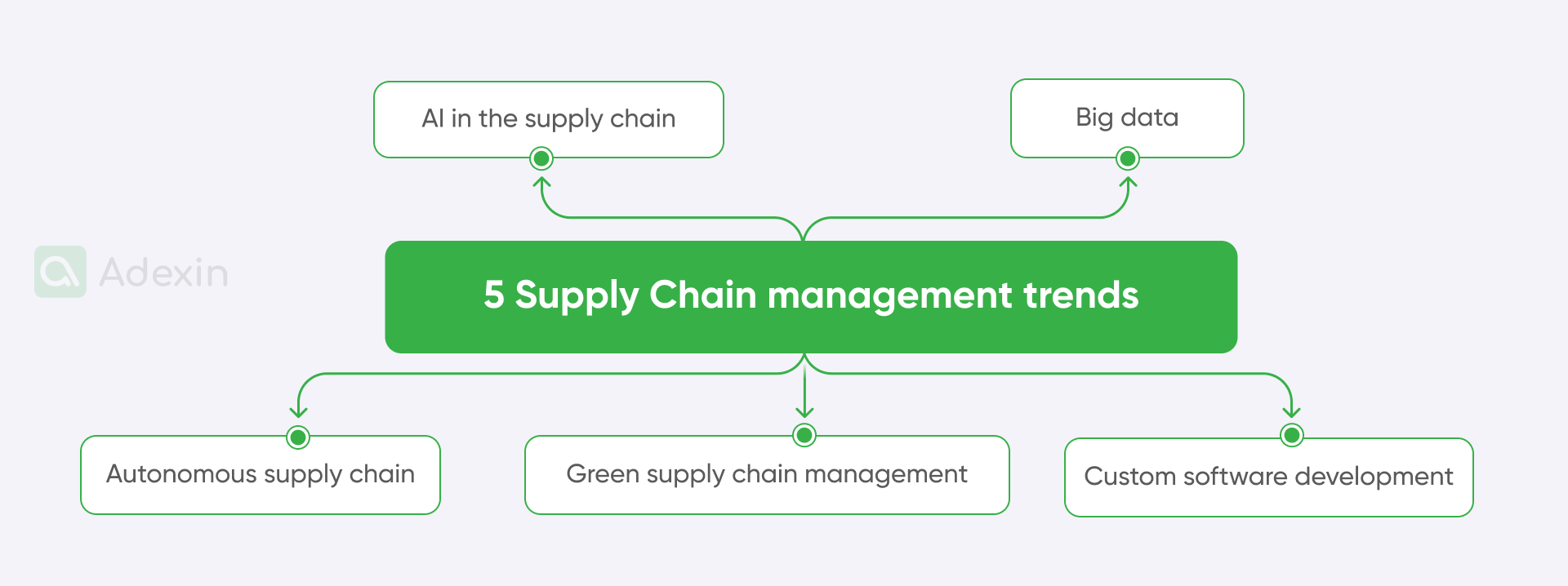

5 supply chain management trends in 2026

Today’s trends in the supply chain involve using technology foremost in every aspect of operations. They also involve gaining more informative insights from all angles of the supply chain business, whether related to logistics, warehousing, distribution, or transportation.

When you think about supply chain trends, you need to have a holistic view of supply chains and a completely fresh perception of the interconnected network. Cooperation and data exchange between different units of the supply chain have become so important that there is no more room for silos where one part of the business falls apart only because it consumes different resources.

Leveraging technological advancements and supply chain software development is one of the leading future industry trends in management. The future of the supply chain lies in technology that brings cost-benefit. That’s the leading goal companies would like to be focused on.

According to sources, one strong trend in the supply chain for 2026 is supply chain resilience, which can be provided by the green transition. We are discussing independence from energy sources and verifying the trucking industry here. So don’t lose your chance to see where you might expect developments and where you may consider future investments in supply chain management.

1. Generative AI in the global supply chain

Generative AI has already significantly impacted supply chains and stands as one of the most critical trends in the industry for 2026. According to one of the supply chain professionals, Michael Biwer, CEO of CAVALLO (ERP system provider), AI (support artificial intelligence) is now providing capabilities that allow operations to process 7x more orders without extra staff, data analytics for a 2-10x profit increase, reduce manual errors by 90%, and cut order processing time by 80%. The impact of AI on SCM performance revolves around revealing blind spots, helping to identify previously invisible areas, and enabling control tower supply chain operations and advanced analytics capabilities.

When utilizing AI in SCM performance, we focus on measurement tools that consider crucial indicators such as lead time, load rate (LTL, etc.), fuel pricing, inventory management, and on-time performance. These standard data volumes can be easily gathered in-house to encompass the full scope of the supply chain and help with risk management. And taking this data from all stakeholders in the supply chain is also crucial.

The role of AI in measuring effectiveness among many supply chain trends is to handle massive amounts of data and calculate outcomes quickly, providing users, which means logistics planners, managers, and others, with suggested prompts for action.

AI offers accurate forecasts of future trends in supply chain behavior and can manage complex algorithms that reduce wasteful inventory expenses, optimize poorly planned routes, and even guide drivers on how to behave behind the steering wheel.

In 2026, companies will also be paying more attention to how AI decisions are governed and controlled. Transparency, data quality, and human oversight are becoming critical, especially when AI is used for planning, forecasting, and operational decision-making. As a result, many supply chains will adopt human-in-the-loop approaches, where AI supports decisions, but final responsibility remains with people.

McKinsey & Company has revealed that AI in the supply chain helps organizations tackle challenges arising from the complexity of product portfolios. Therefore, based on this statement, with AI, we don't have to worry about the vast amount of very diverse stocks characteristic of eCommerce.

Taking another example from eCommerce in the supply chain, AI can ideally help with document management, which is very saturated and becoming complicated regarding cross-border shipping.

Issues with document compliance in eCommerce are frequently faced by the biggest logistics companies, such as FedEx, that support eCommerce in their routine shipping. But AI can also solve that.

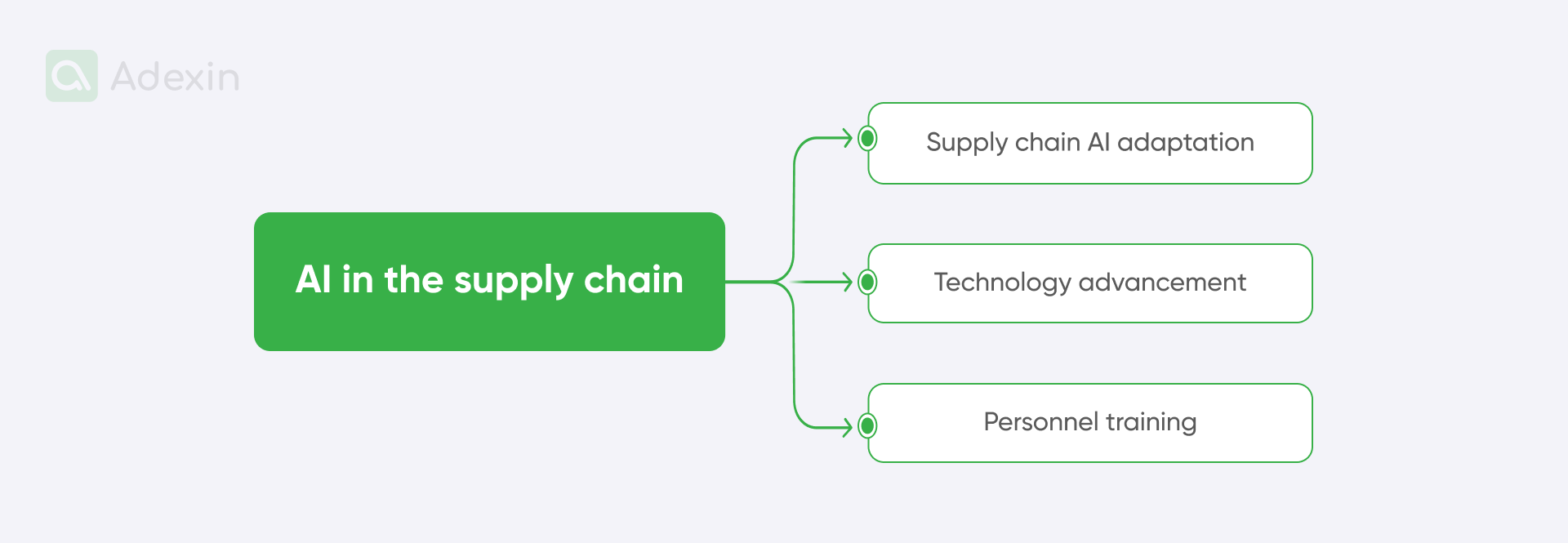

What should be considered when using AI in the supply chain:

Supply chain adaptation for artificial intelligence. Ensure that your Company can adapt AI extensively and avoid shortcomings, as using data partially from one or two stakeholders might not be enough to make the right decisions in supply chains.

Artificial intelligence and technology advancement. Determine if your business can utilize AI in daily operations and ensure sufficient knowledge and technology, such as mobile devices and IoT connectors or integrations with advanced systems that allow for smooth data collection.

Personnel training. Ensure that your staff can use data correctly. Changing people's logistics and supply chain habits is challenging, and it might often be related to difficult hiring decisions.

2. Big data for the supply chain managers

Big data in the supply chain involves fast data processing and the ability to exchange data, allowing supply chain managers to make informed decisions. It also ensures transparency in your business, which is critical to maintaining smooth operations. Research, including 2026 year on procurement from SAP, an ERP provider, shows that advanced analytics, including should-cost analysis, can reduce the cost of component products or services by up to 40 percent.

Data transparency has become a critical requirement in modern supply chains. Companies increasingly expect reliable, timely, and structured data from their partners to improve planning accuracy, reduce risks, and ensure operational stability.

Mutual trust is crucial, but keeping an eye on firm numbers when facing doubts is even better. Therefore, using big data in the supply chain, you can leverage your analytics, which utilizes data collected from all stakeholders and calculations to improve decision-making for all operations across the supply chain.

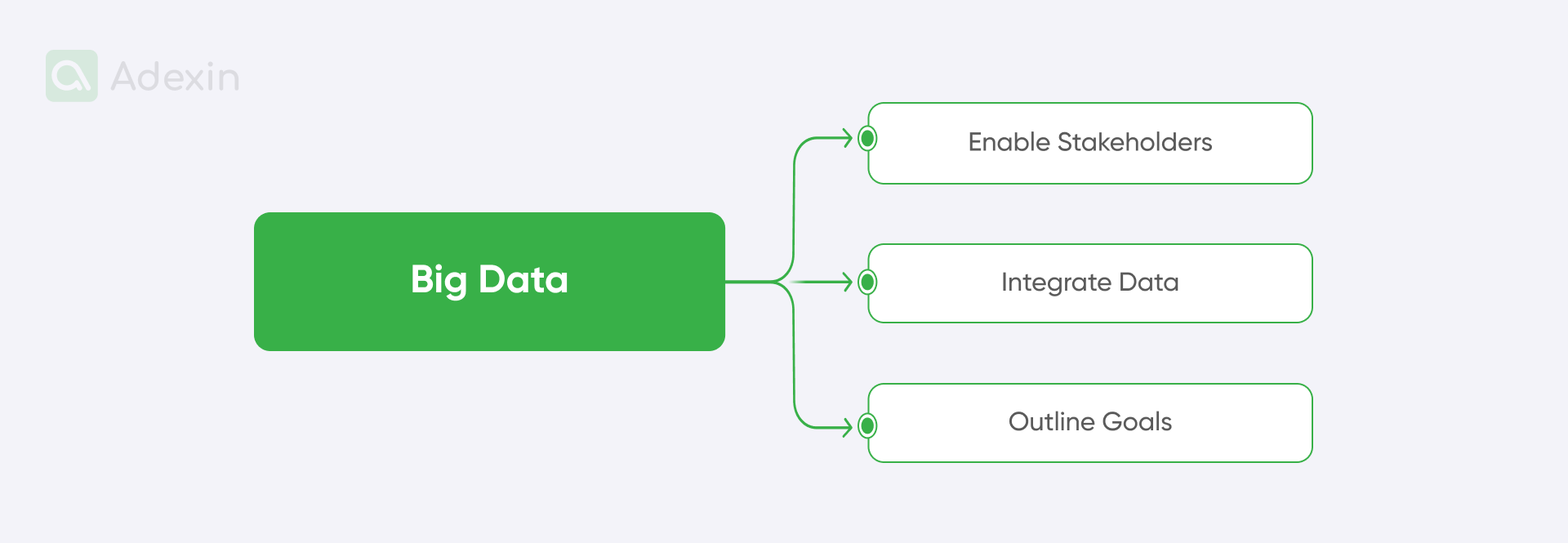

What should be considered when utilizing big data in the supply chain:

Enable stakeholders with data. Ensure that your supply chain counterparts can provide the required data.

Integrate data. Connect all databases and facilities, as well as operations from distinct entities, transportation, and logistics, to ensure you have a comprehensive view of the entire supply chain components.

Outline goals. Data collection is only the first step, the more complex aspect involves analytics, which should provide answers to minimize pain points, ineffectiveness, and additional unnecessary expenses.

3. Supply chain future with custom software development

Custom software development outlines the future of the supply chain by better aligning with specific business needs. Referring to a recent brochure from PwC.com, we see that the trend toward custom software development will strongly compete with low-code solutions. It is clearly stated that 61% of companies leading in the market achieved much stronger results in their development performance while spending 4% less on R&D. This aligns with a better understanding of the supply chain industry. That basically only confirms our approach at Adexin, where we have devoted more than 10 years to achieving the right results by listening to the needs of our customers and employing firsthand expertise from the supply chain.

In both cases, companies in the supply chain can obtain the most suitable solution for supply chain leaders on the journey of digital transformation. Still, custom software development like TMS and Fleet MS development is far more advanced and better tailored to their business complexity.

We enable businesses with not only web but also mobile development using technologies based on React Native, Flutter, and others. By using various approaches, we ensure agility with projects that require connecting with legacy systems. From our experience, we know that mobility plays a crucial role in today's transportation industry.

For example, drivers use a mobile app to access the system. Shortly after authentication, they are available to connect with the portal. So, they can send updates about delivering cargo in real-time. Many more events occur in the background of such an easy task as confirming digital proof-of-delivery (POD).

Here we suggest getting acquainted with one of our custom mobile applications for truck owners, which allows optimizing business processes in real-time, as well as simplifying the document flow for delivery operations.

Need help with custom mobile app development?

Learn how we can boost your logistic business processes

Explore moreNevertheless, custom software development in the supply chain is now exclusively for large companies. The accessibility of custom software development services has become so widespread that many companies in the supply chain landscape are more likely to choose a custom software development partner to obtain an agile solution that will be profitable for them for years and secure their business in the uncertain future.

The choice of custom software development provides resilient supply chains and ensures supply chain agility. Supply chain resilience has its superiority among today's business operations.

Companies today opt for custom transportation management system (TMS) development to enhance overall supply chain activities. While there are numerous benefits associated with custom TMS development, it's not the only example. Custom software development facilitates the integration of multiple systems and solutions, including route planning and document digitization systems.

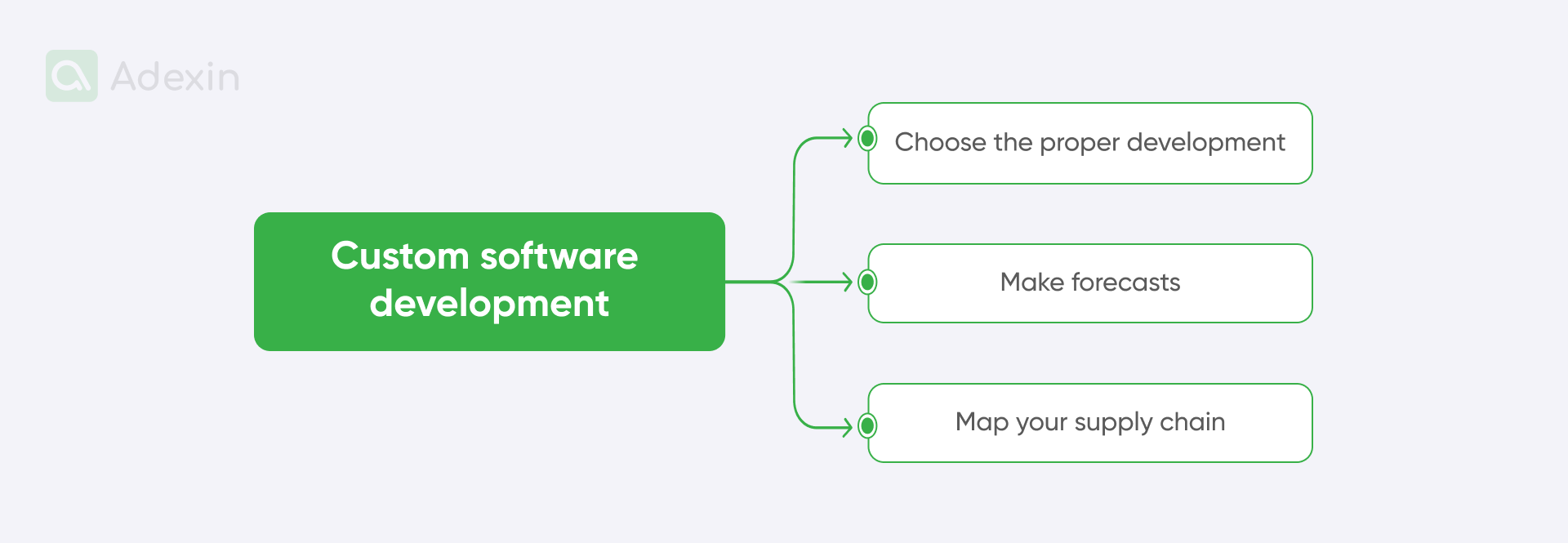

What should be considered when implementing custom software development in the supply chain:

Choose the proper developer. Select a software development partner with extensive experience and expertise in the supply chain who utilizes the required technology.

Make forecasts. Elaborate on a long-term plan for extending your custom software with additional features that will enable your business to tackle the future challenges of the supply chain and help with supply chain planning.

Map your supply chain. Ensure that you have mapped all supply chain activities that must be integrated and digitized by the custom software.

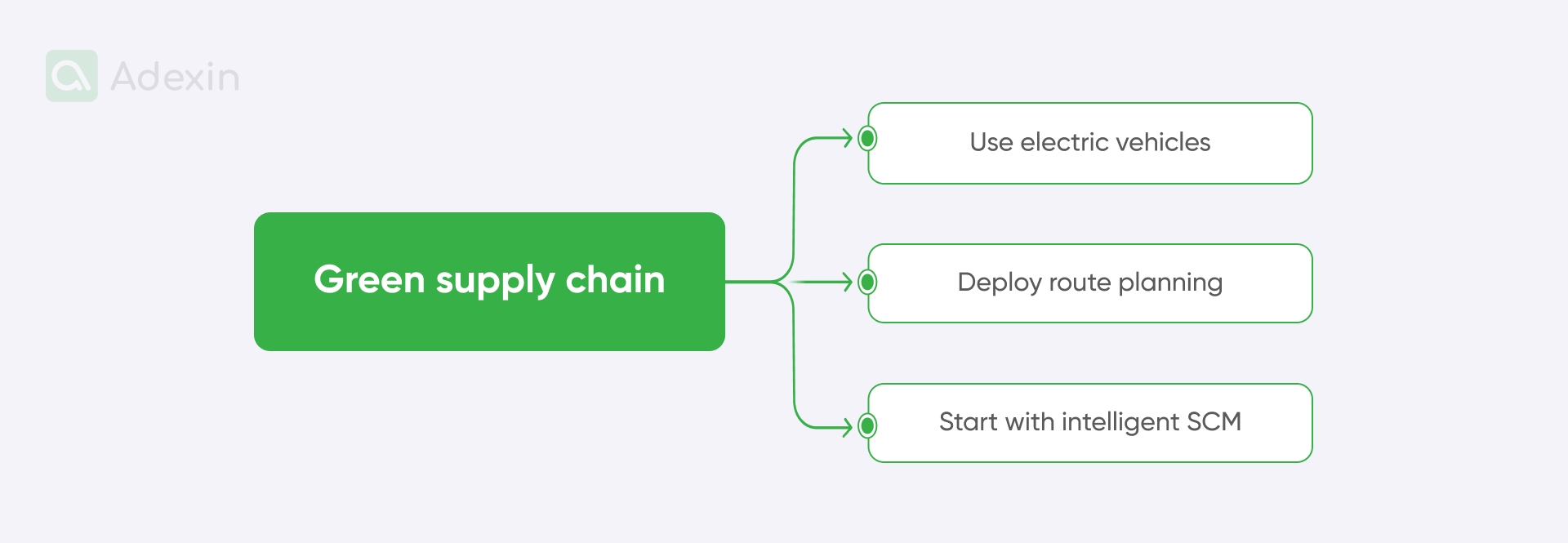

4. Green supply chain management

Green supply chain management involves implementing sustainable practices within the supply chain to mitigate environmental issues. Reducing CO2 emissions emerges as a prominent trend in supply chain management, indicative of its future trajectory.

One key goal was transforming supply chain practices that harm the environment and society. Freight transportation, including warehousing and ports, contributes to greenhouse gas and soot emissions. If current trends persist, it will become the largest source of emissions by 2050. Overall, supply chains generate 60% of global carbon emissions. Thus, sustainable supply chains are crucial for achieving net-zero emissions.

Supply chain procurement often needs embedded green practices, necessitating companies to monitor suppliers for compliance with green policies.

Businesses strive for complete transparency in their processes to ensure they are not perceived as contributors to environmental degradation. For example, the recent “Poland 2025: Europe's new growth engine” brochure from McKinsey shows that EU emissions targets are based on a carbon price floor of EUR 20 to 30 per ton of CO2, which is set to rise progressively until 2030. Another initiative from the EU is its target to raise the share of renewable energy sources (RES) in total consumption to 19 percent by 2020.

In 2026, sustainability in supply chains is no longer optional. Companies are required to track emissions, report on their environmental impact, and ensure compliance across their entire supplier network. As regulations tighten, businesses are increasingly relying on digital tools to automate sustainability reporting and monitor their environmental performance.

In many jurisdictions, adherence to green policies becomes obligatory, compelling companies to comply with regulations to avoid penalties. Consequently, they are inclined to engage only with partners prioritizing environmental considerations.

Sustainable supply chains have become imperative as customers increasingly prioritize environmental awareness. Joint social commitments and governance initiatives will further strengthen this trend in 2026. Therefore, it's worth considering green logistics in your supply chain management.

What should be considered to comply with green supply chain practices:

Use electric vehicles. Utilizing electric vehicles can ultimately lower CO2 pollution. Therefore, consider incorporating electric trucks into your fleet.

Deploy route planning. Implementing software for route planning can help you reduce fuel usage by selecting the most suitable routes.

Start with intelligent SCM. Employ technologies such as AI, big data, and custom software development to achieve agile solutions and enhance decision-making processes that comply with green practices.

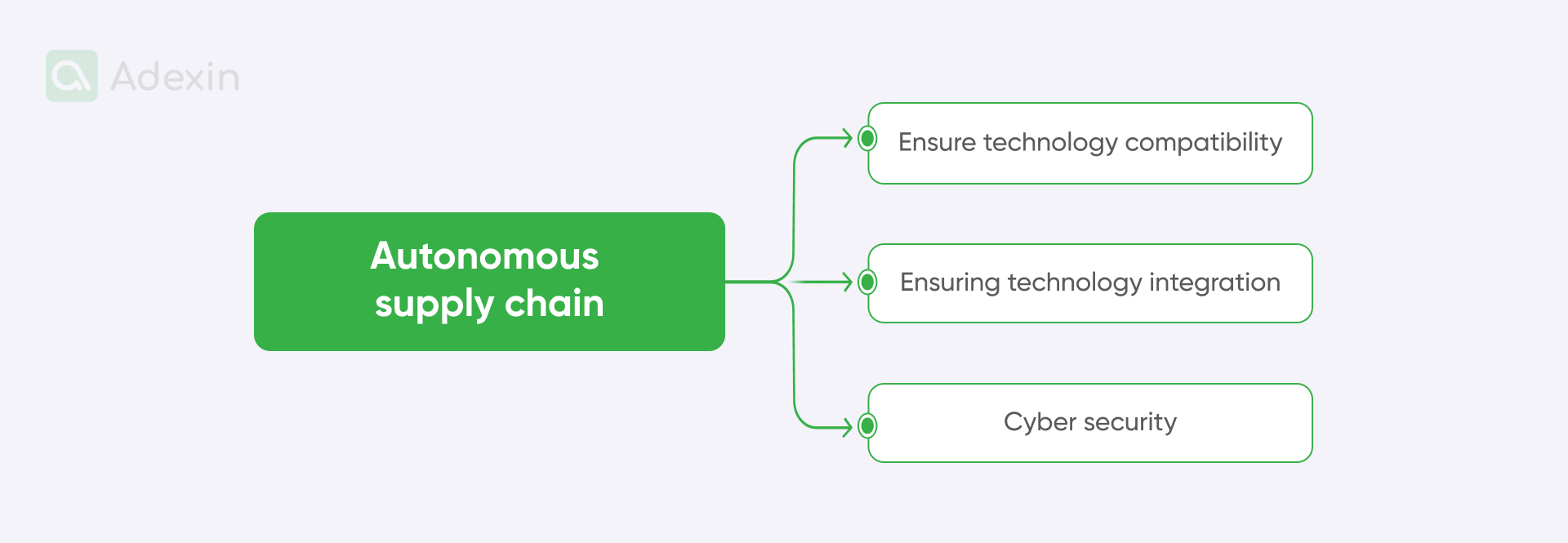

5. Autonomous supply chain

An autonomous supply chain involves embedding robotics and automation in your supply chain operations. This trend is moving towards autonomous vehicles in warehouses and distribution centers. Relying on the “MRO 2025: The Future of Digital Supply Chain is Now” report, digital technologies can improve the productivity of purchasing organizations by 33% while improving flexibility and overall efficiency.

Simultaneously, this is integrated with software that collects data from technological components, retrieves data from vehicles, IoT connectors, and sensors, and later processes data on orders and more.

Looking through our experience, we can give an example of integrating telematics systems via API. Other examples are related to connecting third-party dash cameras, which allow, for example, detecting drivers' violations of the road rules, such as not following the speed limit or not stopping at a red light. Cameras integrated with the software can help spot any event on the road. Of course, all these features require suitable configuration to trigger the right system actions; for example, when the driver's speed exceeds 20 km/h, the system admin can collect data on these violations.

Automated processes are expected to expand significantly in 2026. This will address personnel shortages and training requirements as well as technological advancements. The US is encouraging companies to onshore semiconductor production and has taken steps to address supply chain issues. Intel is investing $20 billion in a new chip manufacturing facility in Ohio, scheduled to start production in 2026.

A great example is the UPS SCS warehouse transformation from a distribution center in the Netherlands to a fulfillment center. Here, shelving was partially replaced with modern automated warehouse modules. It represents cutting-edge retail and integrated manufacturing support, facilitating efficiency across all warehouses and enabling seamless eCommerce fulfillment.

What should be considered when implementing an autonomous supply chain:

Ensure technology compatibility. Ensure your staff is qualified to work with automated technologies such as machines, tools, and robots in your supply chain and manufacturing. Additionally, ensure that technological advancements do not adversely affect less modernized parts of your business.

Ensuring technology integration. It is essential to ensure the seamless integration of different technologies within the autonomous supply chain. This includes the integration of hardware, such as robotics and automated vehicles, with software systems for data collection, analysis, and decision-making.

Cybersecurity. With the increasing reliance on digital technologies and interconnected systems, cybersecurity is becoming a primary goal. Implement robust cybersecurity measures to protect the autonomous supply chain from cyber threats and data breaches.

Are you in search of a reliable tech partner?

Adexin can help with advanced logistics solutions

Contact usFinale takeaway

The supply chain is entering a new phase focused on resilience, automation, and data-driven decision-making. Companies that invest in adaptable technologies and flexible software solutions are better positioned to handle disruptions, regulatory changes, and evolving customer expectations.

Software plays a crucial role in this transformation. Businesses can ensure future flexibility and resilience by investing in customer software development. Start by identifying and implementing one of the key supply chain trends to disrupt your current processes and drive improvement.

At Adexin, we strive to provide most logistics-related services. Custom node js development services can help you be more agile and adapt to supply chain trends seamlessly. Find out more about future trends in supply chain management with us.