Warehouse management systems, or simply WMS systems, are the software that companies use to manage their warehouse facilities. WMS supports a wide range of areas, with its main capabilities managing goods and material flow in a distribution facility. WMS software is mainly adapted by contract logistics, fulfillment logistics, and manufacturing companies that require warehouses to supply their production lines with raw materials and other components.

The range of adaptations for warehouse management software is very wide. We cannot close it in a few industries. Businesses that want to manage their inventory by picking and packing, getting real-time visibility into stock levels (inventory management), and controlling shipping volumes through outbound and inbound analytics will likely implement warehouse management systems software to gain total control over their operations.

WMS warehouse management system: all you need to know

Warehouse management systems software is a supportive system that enables warehouses to control their items digitally. Companies using WMS systems can manage their day-to-day operations more effectively by monitoring the ongoing material flow through their business cycle.

It is no coincidence that companies are adopting WMS systems globally. Research from several industries confirms that adopting a warehouse management system is a fast-moving trend. Based on Statista insights, the revenue of the e-commerce industry in the U.S. from 2019 to 2029 is significantly increasing, and during the mentioned decade, it will rise by over 200%, from nearly 550 billion U.S. dollars to almost 2,000 billion U.S. dollars by the end of 2029.

So, as stated, it is not a coincidence, because global demand for goods is still increasing. Looking at the UE market, despite many analysts talking about polarization in GDP per capita, demand for specific goods didn't decrease but even increased. Even during the COVID-19 crisis, the GDP per capita growth index for metropolitan regions (per 100 people) has shown nothing has changed. So, de facto, even despite the crisis, the economy hasn't suffered as much as the mass media proclaimed. In this case, the balance was secured by a shift from general e-commerce to healthcare e-commerce. The pandemic spurred SMB businesses and companies such as UPS from the U.S. and launched them to higher ground with services. USP's fourth-quarter 2020 consolidated revenue increased to $24.9bn, a 21% increase from the same period in 2019. FedEx and other giants were no exception in this case.

We need to be clear that many factors play a role in increasing business. However, according to UPS, the lowering of inventory roles in the supply chain characterizes the shift in business that reduced logistics costs and simplified fulfillment. This couldn't be possible without an efficient warehouse management system.

Need help with warehouse management system development?

Learn how we can boost your logistics processes

Explore moreThe main features of a warehouse management system

Well, adapting the warehouse management system by companies such as UPS seems to be an easy task. It is a global business, and they've already been on this train for a long time. It's different when you're a small or medium-sized business, where you must focus on the same factors as UPS. These are likely narrow margins, fuel costs, storage costs, fulfillment service costs, and the logistics a company may need. So, again, this all revolves around costs, costs, and costs.

To make business cost-effective, you cannot adopt a warehouse management system with a full range of features. You need a suitable solution for your factual warehouse operations. Thus, your WMS software should include five main features.

Here are the warehouse management system features:

Inventory Management. Tracks inventory levels and movements. Here, you gain real-time inventory insight to ensure accuracy and efficiency. You can also use asset-specific criteria such as FIFO, LIFO, FEFO, batch, pack size, storage areas, and warehouse.

Order management. Manages order fulfillment processes. It allows you to ensure accurate and timely order processing to meet customer demands.

Personnel management. Optimizes employee productivity. People come first, so you need to schedule and track employee activities and help allocate resources efficiently. Workforce management is a key player for SMBs in this case.

Receiving and putting away. This function manages the receipt of goods and their placement in the warehouse. A core function is to ensure efficient and accurate putting away to optimize space utilization and inventory availability.

Reporting and analytics. Provide insight and performance metrics. Assists in decision-making by offering insights into performance indicators, trends, and areas for improvement.

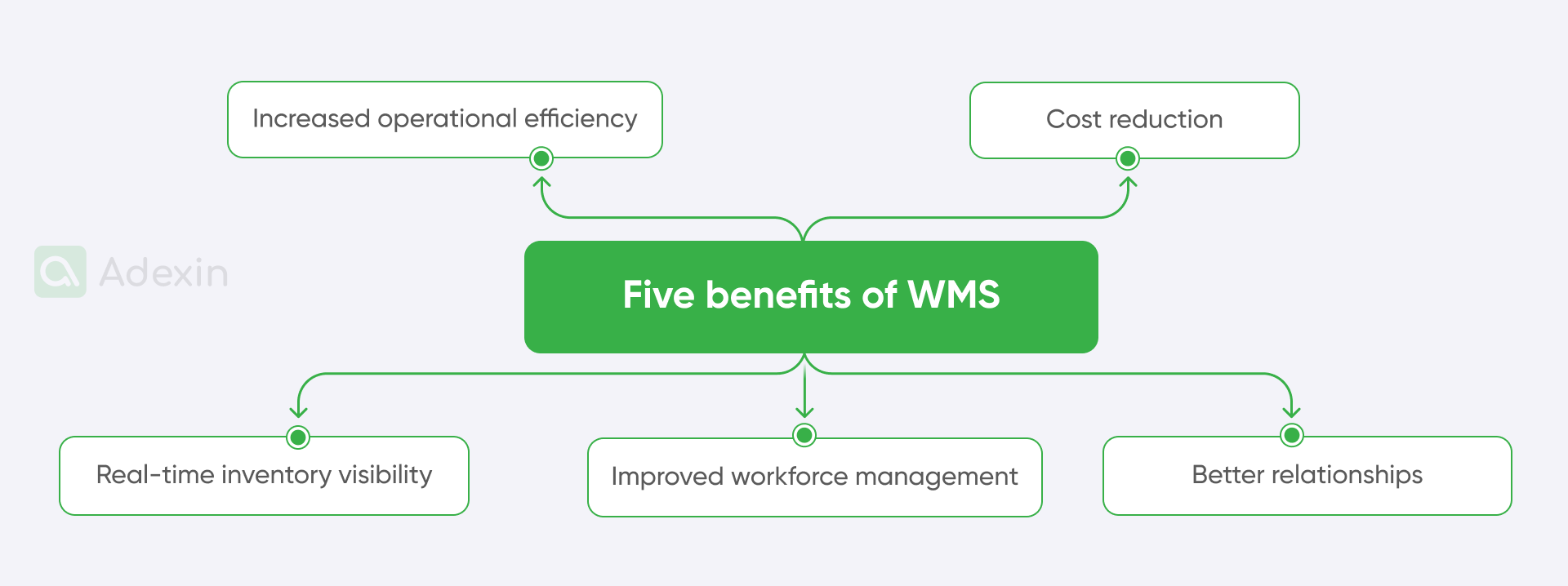

Main benefits of a warehouse management system for small and medium business

SMBs can benefit in a variety of ways from a WMS system. The main benefits are naturally converting their financial systems into more cost-effective ones. Companies can keep low stock volumes (inventory management), replace much manual work, etc.

Here are five benefits of WMS software for small and medium-sized businesses:

Increased operational efficiency. WMS systems automate warehouse processes from receiving to delivery, increasing efficiency, minimizing errors, and integrating with ERP and fleet systems to ensure smooth operations.

Cost reduction and waste management. WMS software optimizes inventory handling of perishable goods, minimizes waste, and maximizes warehouse space efficiency through advanced simulations, saving time and costs.

Real-time inventory visibility. Using barcodes or RFID, the WMS provides instant visibility into inventory movement, supporting accurate forecasting, just-in-time strategies, last-mile delivery, and improved traceability during recalls.

Improved workforce management. The WMS forecasts labor requirements, optimizes schedules and routes, and assigns tasks based on skills and proximity, supporting a productive and organized workplace.

Better relationships with customers and suppliers. Customers benefit from accurate orders, faster deliveries, and better service, while suppliers experience streamlined operations and better collaboration, improving overall relationships.

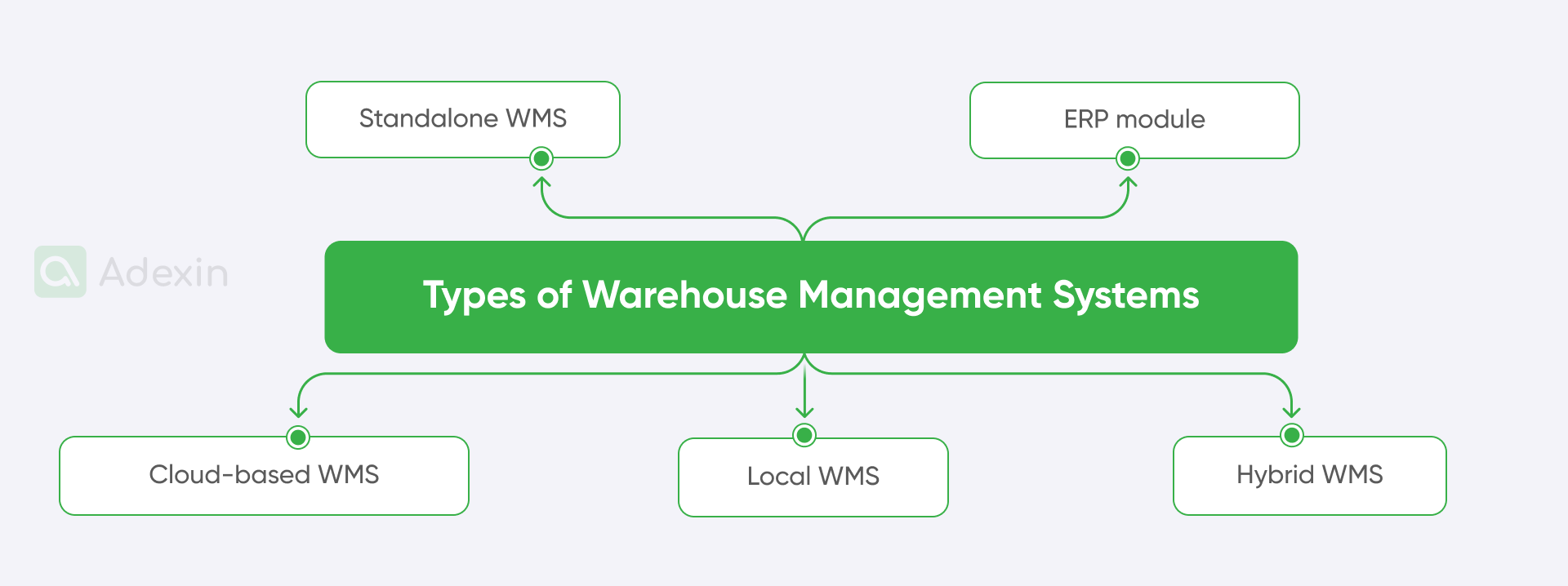

Types of warehouse management systems for inventory management and beyond

We can debate which system is most suitable for business, but from a technical standpoint, you can rely solely on three central adaptations.

Here are the several best-in-breed types of Warehouse Management Systems:

Standalone warehouse management system

Often referred to as an inventory control system. This type of WMS system is easy to implement and cost-effective but offers limited functionality. This type of WMS system gives the company complete ownership of the solution. It's much safer, but running application updates will be more complex. You need, most likely, someone from the IT system who will work solely on WMS to fix bugs and help you with further integrations. You may also choose and hire a custom software development company to build such a solution for you, and then you can rely on continuous support.

ERP module

This type of WMS software is integrated with larger enterprise resource planning (ERP) systems. So, frankly speaking, this type provides similar functionality to a standalone WMS but may have less robust capabilities due to the solution provider's broader focus on ERP modules. Here, for example, you can get one layer to your ERP that will work with WMS functions, but it will not provide you with full capabilities, such as building a WMS layer completely based on custom software development.

Cloud-based WMS

WMS cloud-based offers flexibility, scalability, and accessibility from anywhere with Internet access. It is ideal for companies requiring rapid deployment and minimal IT infrastructure. Cloud-based systems streamline warehouse operations without the need for extensive on-site hardware. Here, you instead rely much more on cloud environment providers, thus limiting your

Local WMS

For many SMBs, local WMS can be more suitable as it provides full control over hardware and software. This makes it suitable for companies with specific security or integration requirements that prefer in-house systems management. Local solutions allow customization and direct oversight of critical data and operations.

Hybrid WMS

You can extend your infrastructure and combine features of cloud-based WMS and on-premises systems; this type offers deployment flexibility and efficient data management. Hybrid solutions combine the scalability of cloud-based availability with the management control of core operations within an organization's infrastructure. It is a complex solution, but companies are deploying it to diversify their business and lower dependencies from a single software infrastructure. In many cases, deploying hybrid WMS is based on data flow throughout the organization.

Warehousing software for supply chain management

When considering a warehouse management solution for your supply chain, it's crucial to focus on critical elements that truly matter:

Scalability. Ensure your WMS can grow with your company's needs without compromising performance or functionality.

Integration. Compatible with existing ERP, and transportation management (TMS) to streamline operations and data flow.

Customization. The ability to customize and personalize the system to fit specific processes and warehouse requirements.

Ease of use. User-friendly interface and intuitive features that simplify training and daily operations.

Analytics and Reporting. Robust analytical capabilities that provide insight into warehouse performance and facilitate data-driven decision-making.

Support and maintenance. Access to reliable support services and ongoing system updates to ensure smooth operations and minimal downtime.

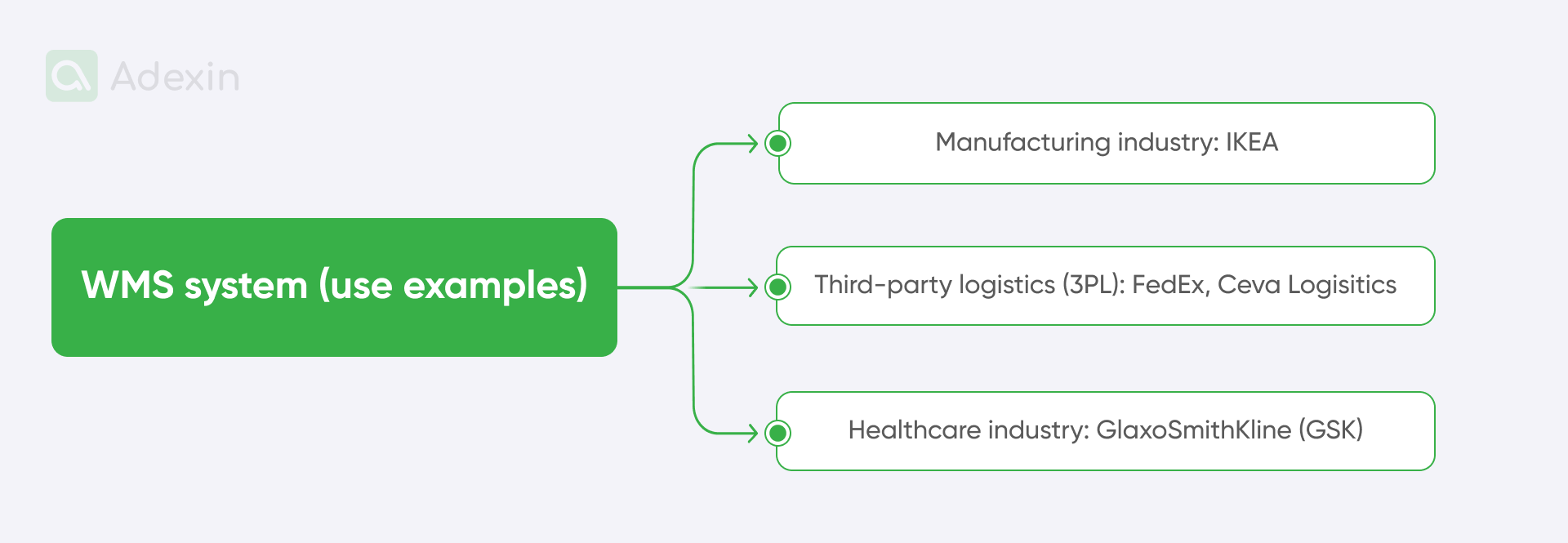

Who is using warehouse management system: life examples

Well, we have worked with companies that are deploying warehouse management systems, and we clearly state that these tools are essential in almost every industry. Despite that, they're never deployed alone on the premises and are often supported by other solutions like truck owners' assistance applications, paperless DMS, parking management systems, etc., which we successfully implement and thereby help businesses accelerate and increase their income.

Warehouse management systems software is commonly utilized by more prominent distributors, e-commerce fulfillment centers, fourth-party, third-party logistics (3PL) providers, contract logistics, and many others. We can often see WMS deployment among those managing multiple warehouses and SMBs focused on business quality delivery. That might be an extensive business, from healthcare to high-tech and chemical, that integrates with transport and logistics systems to enhance efficiency.

Here are examples of businesses that are using the WMS system:

Manufacturing industry

Companies like IKEA from Scandinavia work with various stakeholders and own manufacturing facilities worldwide. They're using the WMS system for their distribution centers, supply chains, and manufacturing facilities.

Third-party logistics (3PL) companies

Third-party logistics companies are companies that extensively provide contract logistics services, for example. Companies such as FedEx, CEVA Logistics, and DSV from Scandinavia provide their services all over the world by using integrated WMS that can collect data from multiple warehouses.

Healthcare industry

In this case, we can mention companies focused solely on storage and transportation solutions, like UPS Healthcare, which provides pharmaceutics storage. Inventory management and transportation often require fridges and other areas that can be ensured. On the other hand, GlaxoSmithKline (GSK) is using WMS in its production facilities while other logistics companies are still doing warehousing and deliveries.

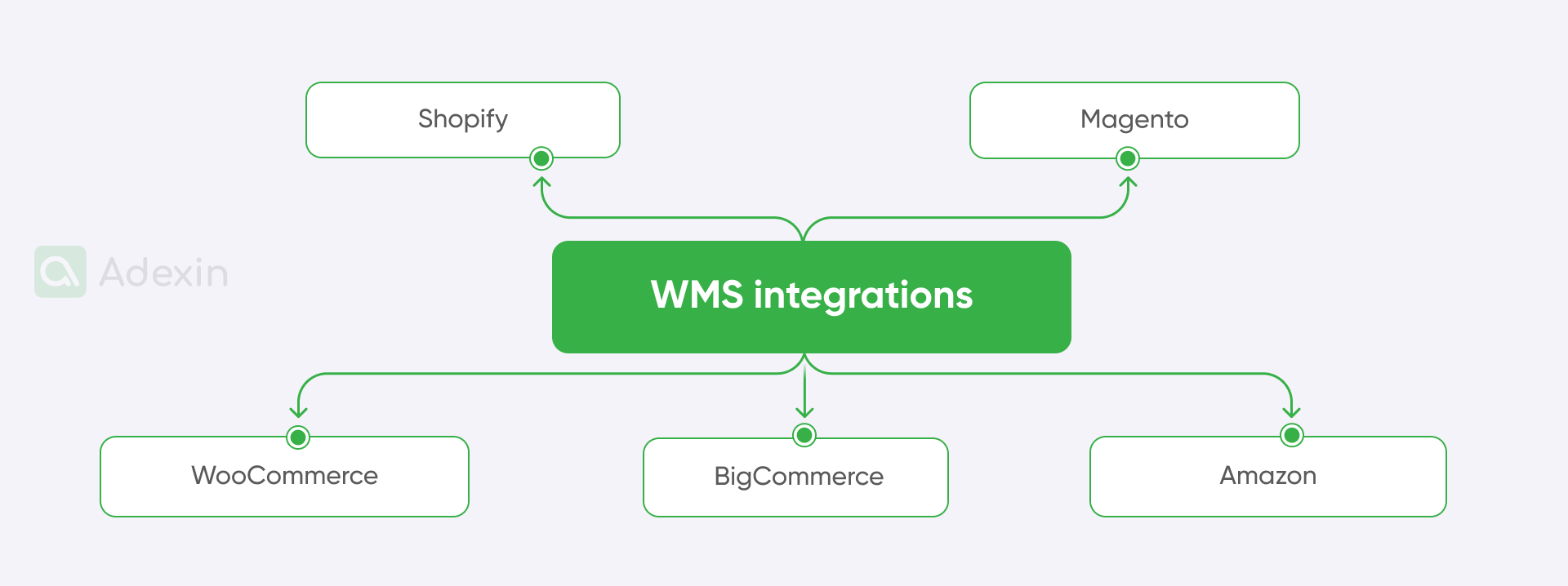

WMS integration with marketplaces: who should use it?

The WMS system should complete to some point your entire landscape of distribution processes. In most cases, system WMS integrates with eCommerce platforms to streamline operations and support order fulfillment.

How does it work? Let's take an example of the company Bang & Olufsen, which is a producer of high-quality sound systems. The company originally comes from Denmark, but not many know that its distribution center is located in the Netherlands. They’re using external services for order fulfillment, like a warehouse with a WMS system to run their distribution.

There are other examples of such cases and various companies are integrating different platforms. For small and medium-sized businesses the same as much bigger companies in eCommerce becomes important to integrate external platforms from online stores.

Here are some common examples of integrations of WMS with external platforms:

Shopify: A popular e-commerce platform that allows companies to create online stores and manage products, inventory, payments, and shipping.

Magento: An open-source e-commerce platform known for its flexibility and scalability, ideal for businesses with more complex requirements.

WooCommerce: A customizable open-source e-commerce plugin for WordPress, making it easy for businesses to add e-commerce features to existing WordPress sites.

BigCommerce: A robust e-commerce platform that provides businesses with tools to create and manage online stores, offering strong SEO and multi-channel sales capabilities.

Amazon: One of the largest online marketplaces in the world, offering companies the ability to sell products to a global audience with integrated fulfillment services through Fulfillment by Amazon (FBA).

Are you in search of a reliable tech partner?

Adexin can help with advanced logistics solutions

Contact usFinale takeaway on warehouse management

By implementing a WMS, businesses can gain a significant competitive edge. Improved efficiency, cost savings, and enhanced customer and supplier relationships contribute to more successful and sustainable operations.

Looking for the perfect WMS? Consider these key factors: scalability, integration, customization, ease of use, analytics & reporting, support & maintenance.

Don't let size hold you back! WMS solutions are perfect for businesses of all sizes, including small and medium-sized businesses (SMBs), distributors, eCommerce, 3PL providers, manufacturing, and healthcare.

Ready to unlock these benefits? Learn more about WMS solutions from the experts in your industry. We have been working in custom development of web solutions for logistics, transport, and supply chain over the past years and will help you implement ideas, expand your business, and gain additional profit. Get a WMS or other systems suitable for your business.