Let's outline what is in this article. So, after reading this article, you'll get to know the key points highlighted below:

First but not least, we're explaining what operations are. So, you can learn more about goods in the supply chain. It links more about logistics processes and what they are.

So, by the second, in fact, we dive deeper into aspects of the management process in logistics to help you re-evaluate them. So, frankly, here you can find out what is behind processes such as inventory management, internal transport management, materials management, etc.

The third point that we want to outline is outsourcing in logistics. Here, you'll discover the key facets that help manage your carriers more effectively. We're also sharing useful tools needed to be more effective, such as software solutions today.

Let's buckle up...

What are logistics operations?

Logistics operations are the collection of complex processes concerning operations in supply chain segments, such as transportation, and all that is included in the warehouse, such as distribution. All that we share here comes from the most successful logistics management companies.

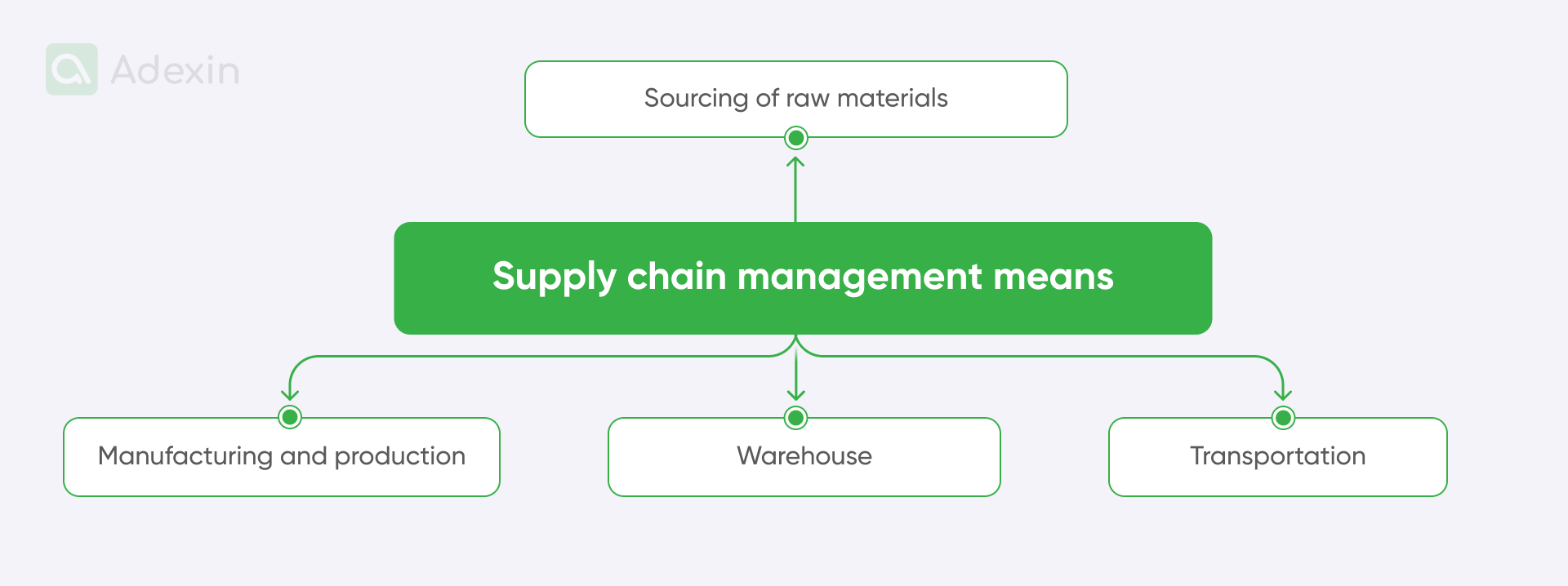

Supply chain management means

If we focus solely on the supply chain, then we perceive logistics operations from the perspective of interconnected elements and stakeholders. We can see that the supply chain management includes components such as:

Sourcing of raw materials. This part is about all that is related to extracting raw materials and delivering them to the manufacturing industry but also food production. In fact, that element can include mining companies, whatever that will be from gas & oil production (actually extracting), mining, etc. but also farms that need to harvest their natural crops for food production.

Manufacturing and production. This part is very broad, but it's mostly based on production, goods assembly, and food production. Manufacturing is essential for supply chain management, and here, raw materials are shaped into a product and shipped further within the supply chain to distribution centers or direct recipients. The same is related to the food industry, where meals or animal food are produced.

Warehouse. This is a vast element of logistics operations and supply chain management. All raw materials and products should be stored in warehouses. Wherever the goods are going to be shipped, they need to be properly stored. Warehouses also serve as distribution centers where goods are not only stored but also managed internally, and this also links to warehouse operations explained below.

Transportation. All goods, whether from a mining facility or production or if they are already shipped to end customers, are transported in various ways. Companies are using trucks and trailers, sometimes, these are smaller delivery trucks for small packs in B2C and e-commerce. Transportation companies include various modalities such as rail freight, air freight, sea transport, etc. Goods can be transported by intermodal transport on long distances worldwide or in short delivery modes such as B2C.

Warehouse operations means

Logistics operations include warehousing. Here, we think strictly of the, which completes the entire supply chain management, but its complex internal requirements create a completely new area of operations, which is still part of logistics. Warehouse operations are included in:

Material handling. Efficiently move, store, and control materials using conveyors and forklifts.

Shipping (outbound logistics). Transporting finished products to customers, ensuring timely and cost-effective delivery within the outbound logistics process.

Receiving (inbound logistics). Receiving and processing incoming materials, verifying accuracy, and updating inventory within inbound logistics.

Order picking. Picking products from inventory to quickly and accurately fulfill customer orders.

Packaging. Preparing products for shipment using appropriate materials to protect products during transportation.

Planning the layout of the warehouse. Organizing physical space to ensure maximum efficiency and safety, optimizing storage and workflow.

What we're saying here above is about major means in warehouse operations that require supply chain management. Just imagine that every aforementioned part of logistics operations here requires people's involvement, so it's about human resource management, asset management, and process management, which may include, last but not least, risk management, return management, last-mile last-mile delivery management, and so on. Look at the next part of this article to learn more about logistics operations and management.

Logistics operations and management: become a key player in logistics

Logistics management is about controlling all the means of supply chain management operations and warehousing. By looking at our internal experience, we can say that good management facilitates how companies turn their efforts into revenues.

I have seen logistics operations where technology adoption was very low, but people could work efficiently with a good network management approach. I mean people because this trait will not leave us long and will remain a huge part of logistics for years.

In the company where I worked, the logistics managers were professional when it came to managing people. One of their skills was a holistic approach that allowed them to see the business both vertically and horizontally while finding a balance between all means. So, they were able to integrate working hours planning with selecting the right people to manage.

Whatever I could say, the business where I worked at the time was lacking high-tech advanced systems. There were systems for transport management but not for managing warehouse operations, such as a Warehouse Management System. So, in fact, we still faced many manual errors, which, based on performance monitoring, were continuously improved and eliminated. So, again, people management.

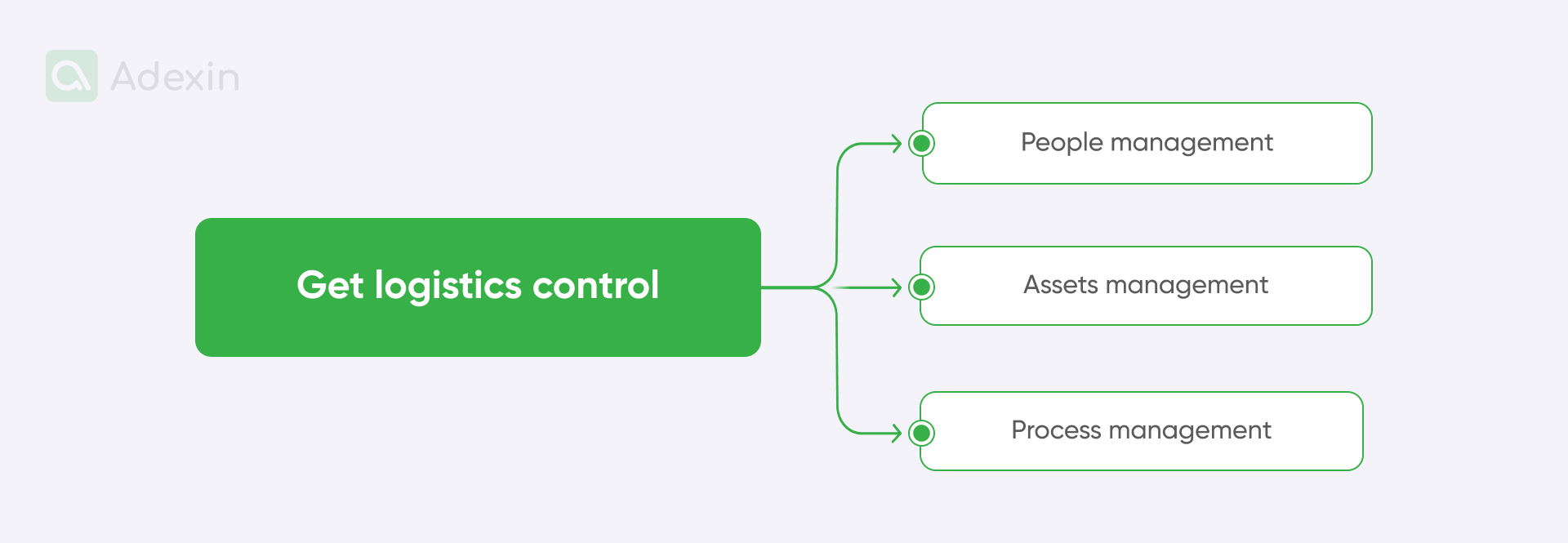

Get logistics operations management control

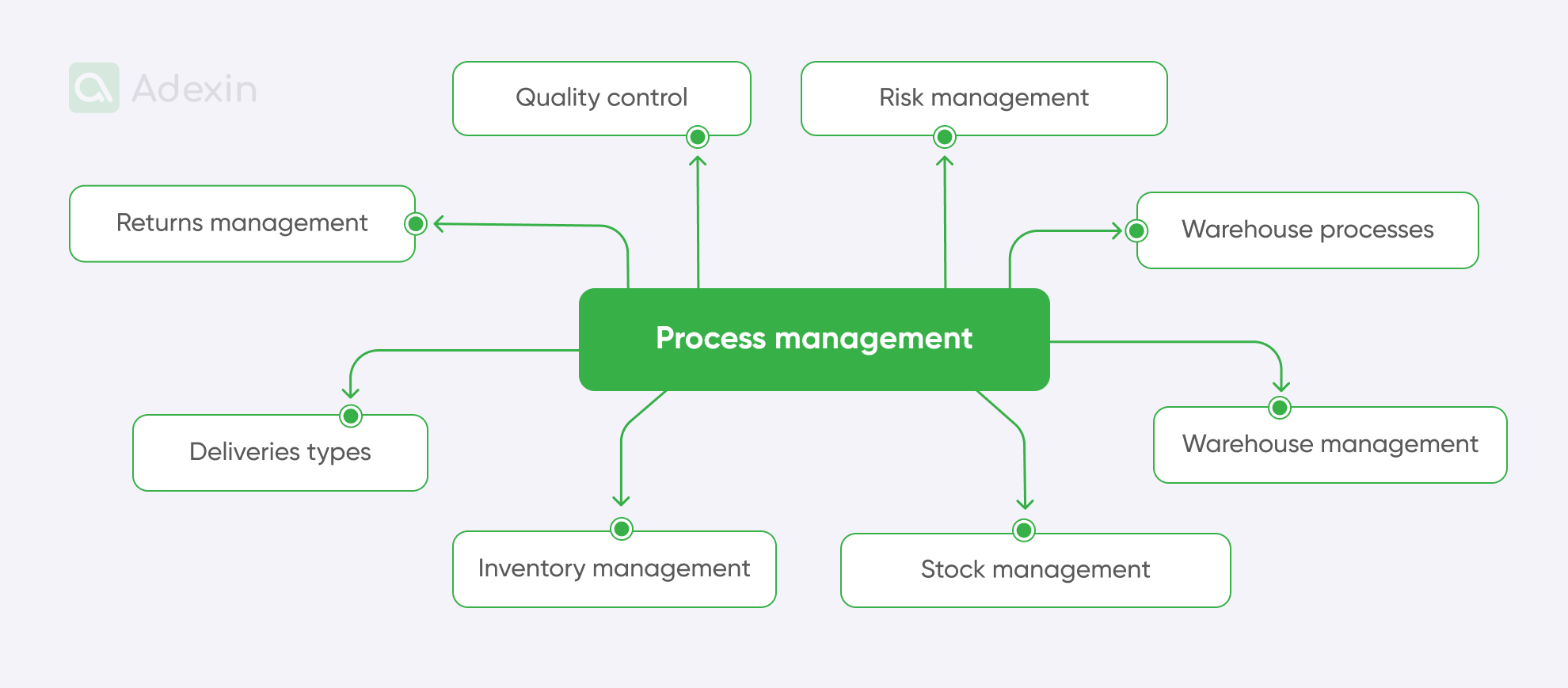

Below, we have outlined the more consistent elements of logistics operations management. As we said above, we have divided them into three groups: people management, asset management, and process management. This configuration makes it easier to explain what is involved.

But nothing gives you more insights than life-case examples. We already put our hands on many projects in our niche, which is logistics, and helped companies to be game changers in their industry. Of course, it's all about gaining control. You need to believe that this is possible in today's logistics operations. Management not from yesterday depends on data but today technology enables you possibilities more than ever.

Here are two cases where we implemented solutions for logistics that helped gain better control:

Shipping document management platform - in the case of this client, you can see that we provided a DMS system to help the company manage its freight documents. Using blockchain technology together with the eTEU team, we were able to develop an excellent solution for maintaining paperless documentation and completely transform the document flow in the company.

Truck owners assistance application for truckers and trucking businesses aimed at optimizing business processes.

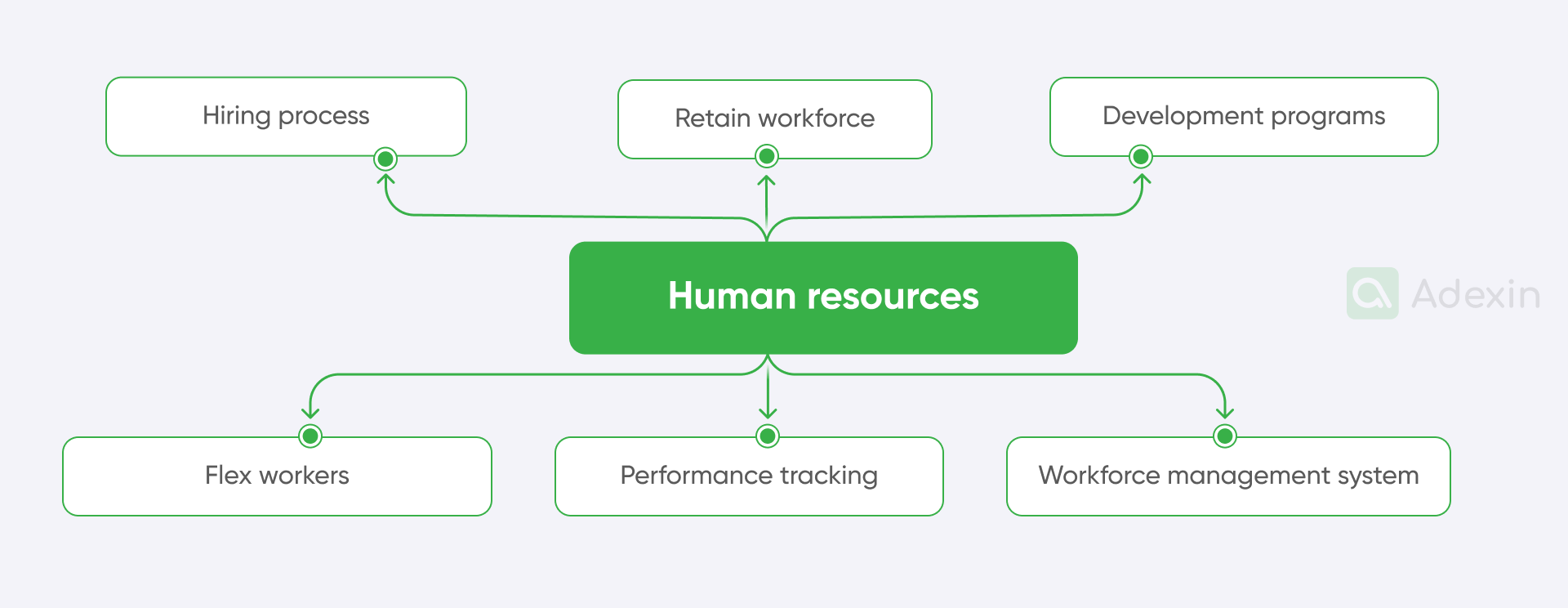

Human resources like a part of logistics operations management

People management here is about logistics workforce management. There are several key points that, as a manager, you should keep under your leans, and here they are:

Hiring process

Targeted recruitment. Your goal is to attract and recruit top talent for your warehouse team. You should understand the specific skills and experience needed for each function's logistics. It's a good time to utilize job boards and industry resources to attract suitable candidates.

Skills assessments. At that point in hiring process management, it is worth implementing aptitude tests with your HR team to evaluate the potential for picking, packing, or operating machinery. This might prevent future errors in your logistics operations per person.

Structured interviews. Design, together with your HR team, interview questions that assess problem-solving, communication, and teamwork abilities. Your HR team is mostly skilled in people, but they must know more about logistics, so don't let them work on their own.

Retain workforce

Competitive compensation and benefits. Consider how to minimize turnover and build a loyal, experienced team. To attract and retain employees, you should offer competitive wages, better healthcare plans, and fair-paid time off.

Positive work environment. This is all about your personal skills. You should foster a culture of respect and collaboration with your team leaders and supervisors. Maintain their safety and provide opportunities for feedback and growth.

Recognition and rewards. As everywhere, it is important to acknowledge and reward exemplary performance to motivate and incentivize employees.

Ensure development programs

Onboarding and training. Invest in continuous learning and upskilling and provide comprehensive onboarding programs. Keep in mind that ongoing training in safety procedures, equipment operation, and warehouse best practices can help you make work easier in the future (that is, error-free).

Cross-training. As a manager, you can think of developing versatile employees by offering training in multiple areas. In fact, this enables them to fill various roles and handle fluctuations in demand.

Career development opportunities. Split the teams and offer mentorship programs and leadership training paths. This will motivate employees and build a strong talent pipeline.

Flex workers

Temporary staffing agencies. Leverage contingent labor to meet peak demand periods. You should partner with agencies to fill temporary positions or address seasonal spikes in workload.

On-demand staffing platforms. Utilize online platforms to access a pool of qualified temporary workers.

Effective scheduling. Become more strategic and schedule flex workers to support peak periods and ensure smooth operations.

Need a dedicated team to develop your project?

Learn how we can boost your business processes

Explore moreWorkforce management system

Real-Time Visibility. Harness technology for efficient workforce optimization by monitoring employee activity or tasks completed and even identifying areas for improvement.

Labor Scheduling and Optimization. Use digital systems to create optimized schedules based on workload, skills, and employee availability.

Performance Tracking and Reporting. Track individual and team performance metrics to identify strengths, weaknesses, and opportunities for improvement.

Individual performance tracking

Quantifiable Metrics. Measure and monitor performance to ensure accountability and provide feedback. Set clear and measurable performance goals based on picking accuracy, packing speed, and adherence to safety protocols.

Regular Feedback. Provide regular performance reviews. Here, you should discuss strengths and areas for improvement. This is a time every year to highlight individual contributions to team success.

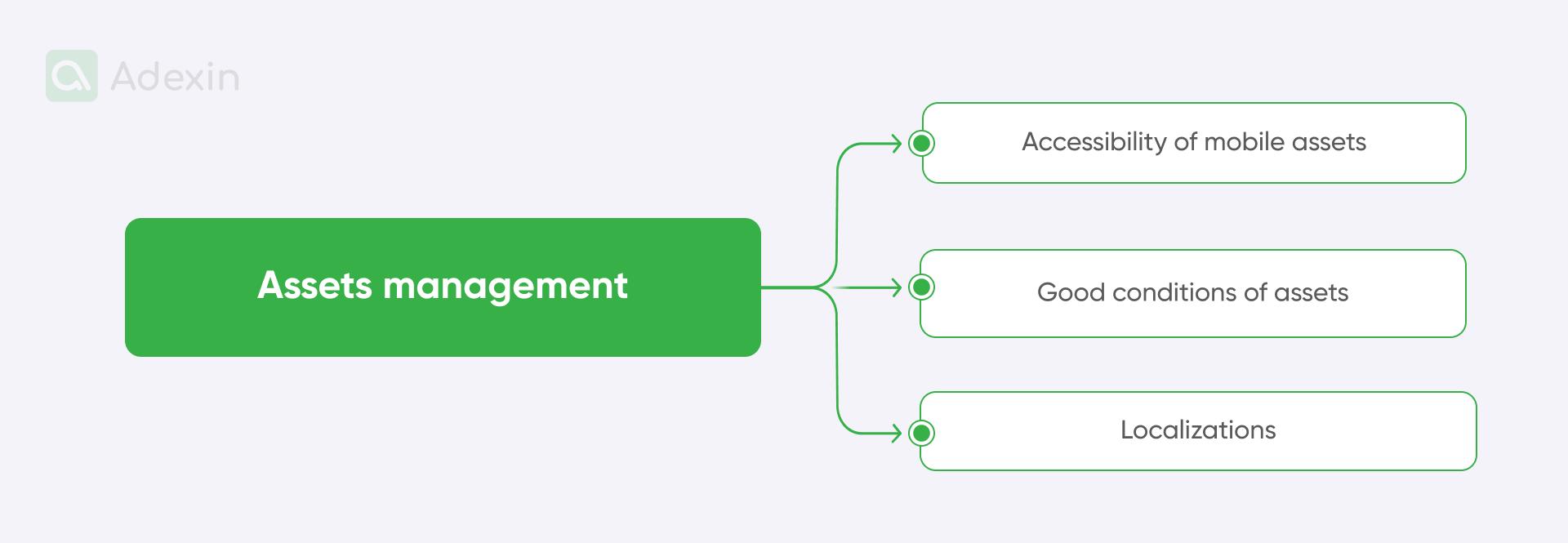

Assets management like a part of logistics operations management

Asset management manages all company assets, whether mobile assets, property, or equipment purchased exclusively or mainly for business use. Assets are mainly part of business accommodation valued in the balance sheet. We can frankly state that asset management is also one of the logistics operational processes, but because of its specific characteristics related to taxation, depreciation, life cycle, and wear and tear, it must be separated.

Regarding logistics operations management, managers are getting various assets to manage and keep them under control. What do you need for asset management?

Preserve accessibility of mobile assets. A logistics company can possess a fleet of trucks, trailers, containers, cars (when it comes to the rail industry), specialized tools and equipment, and internal logistics equipment, such as internal transportation (EPT trucks, forklifts, etc.), and schedule them for daily use for shipping or intralogistics operations.

Keeping good conditions of assets. Logistics management of assets involves taking responsibility for equipment conditions and certifications to keep them up and running. As a manager, you should keep equipment available within scheduled downtime dedicated to reparations and service, etc.

Localizations. If you have a fleet of trucks or several warehouses, it will be necessary to know the exact location of equipment in cases of internal movements for different facility uses. This is one of the key facts for better and more flexible asset logistics management.

Process management like a part of logistics operations management

Logistics operations are the combinations of various processes. From basic things such as managing floor layout where we can store goods without customs clearance to more advanced management techniques related to automation that require engineering knowledge. We need to know how to maintain processes, to set up the right troubleshooting for unexpected issues, but not only for these.

Here is the outline of what is covered by the most essential processes within logistics:

Quality control logistics management

Every logistics company should have a Quality Management System (QMS) in place to ensure that its products meet specific standards and prevent defective items from reaching customers. This can involve inspections at various stages, from manufacturing to warehousing. QMS is crucial in getting customers in because it can give some secure buffer for manual errors, etc.

Risk management for logistics operations

As a manager, you need to identify, assess, and mitigate potential threats throughout the supply chain. This could include anything from transportation delays to damaged goods. So, you're partially focused on what causes issues in the warehouse and administration if transportation means.

Returns management and reverse logistics

Reverse logistics is the process of handling returned items, including receiving, inspecting (checking quality goods), and moving back to the area of inventory management. If goods are okay to be accepted upon return, refunds should be issued. But again, it all depends on the customer's situation.

Deliveries within types of logistics management

Last-mile delivery. The final route of the delivery journey from the distribution center to end customers. So, as it's said, it typically leads goods from a distribution center with truck deliveries to the customer's doorstep or collection points.

First-mile delivery. This is the initial movement of goods from the origin, such as a manufacturer or supplier, to a collection point or distribution center, where they are then distributed to the customers.

White glove delivery. This is often a premium delivery service that involves installing, setting up, and removing debris for complex items like appliances or furniture.

Same-day delivery. Expedited service where goods reach the customer within the same day of purchase.

Overnight delivery. Fast delivery option where goods arrive at the destination the following business day.

No contact delivery. This method minimizes physical interaction, often involving secure drop-off locations or lockers.

Inventory management with warehouse management systems

Just-in-time (JIT) delivery. This is most likely a manufacturing stock management process. It's about receiving inventory only when it's needed for production or sales, minimizing storage costs.

Just-in-sequence (JIS) delivery. The same here, as the JIS delivery of components in the exact order and sequence needed for assembly, which is about maximizing efficiency.

Stock management and inventory control

First-In, First-Out (FIFO). This process in supply chain management is also used in manufacturing warehousing, where it first prioritizes the sale or use of older inventory. Of course, it's also used in the food industry to ensure fresh products for customers and avoid stock expiration.

Warehouse management

5S & lean management. 5S, or even now 6S or 7S, with lean techniques are methods focused on optimizing warehouse space. This is all about organization and processes to improve efficiency and eliminate waste.

Procurement management. This is the process of outsourcing in logistics. It's about acquiring goods and services needed for a business, including sourcing, negotiating contracts, and managing supplier relationships. So, it's all about outsourcing services.

Carrier management. As a logistics manager, you must focus on selecting, negotiating with, and managing transportation providers to ensure efficient and cost-effective delivery. This is one of the most important processes in logistics and supply chain management, and it requires a lot of knowledge about side effects that can occur during transport.

Warehouse processes management

Shipping. Preparing and sending out orders to customers.

Packing. Securing items in appropriate packaging for safe and secure transportation.

Order picking. Selecting and retrieving items from the warehouse to fulfill customer orders.

Data entry. Updating warehouse management systems (WMS) with details like received items, quantities, and storage locations.

Put-away. Strategically placing items in designated storage bins, shelves, or racks based on size, weight, and demand.

Inspection. Carefully examine incoming goods for damage and discrepancies in quantity or specifications compared to packing slips.

Documentation. Verifying paperwork such as bills of lading and invoices to ensure accuracy. For this purpose, companies use document management systems.

Receiving. Processing incoming goods, verifying quantities and quality, and storing them in the appropriate location within the warehouse.

Selection. Choosing the appropriate packaging materials, such as boxes, bubble wrap, or void fill, to ensure secure transportation.

Packing station ergonomics. Designing workstations to minimize physical strain on workers who pack items.

Weight & dimensioning. Accurately measure and weigh packages to ensure proper shipping costs and efficient handling.

Labeling. Attaching clear and accurate shipping labels with customer details, tracking numbers, and handling instructions.

Order selection. Using the WMS, identify orders and the items required to fulfill them.

Are you in search of a reliable tech partner?

Adexin can help with advanced logistics solutions

Contact usFinale takeaway

Logistics operations are the engine of any successful supply chain. By understanding the intricacies of warehouse management, transportation options, and process optimization, you can organize a smooth flow of goods and maximize efficiency. All of this brings tremendous ROI and enhances customer satisfaction.

We offer a comprehensive suite of custom software development services for logistics and resources to help you achieve your logistics goals, from implementing an effective WMS and carrier software management strategy for transportation costs or custom software features for optimizing your warehouse layout. We can guide you every step of the way for all that is needed in supply chains. Contact us today for a free consultation, and let's work together to unlock the full potential of your logistics operations!